Heat shield element for compressed air bypass around combustion chamber

A heat shield, combustor technology, applied in the field of combustors, to solve problems affecting gas turbine power, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

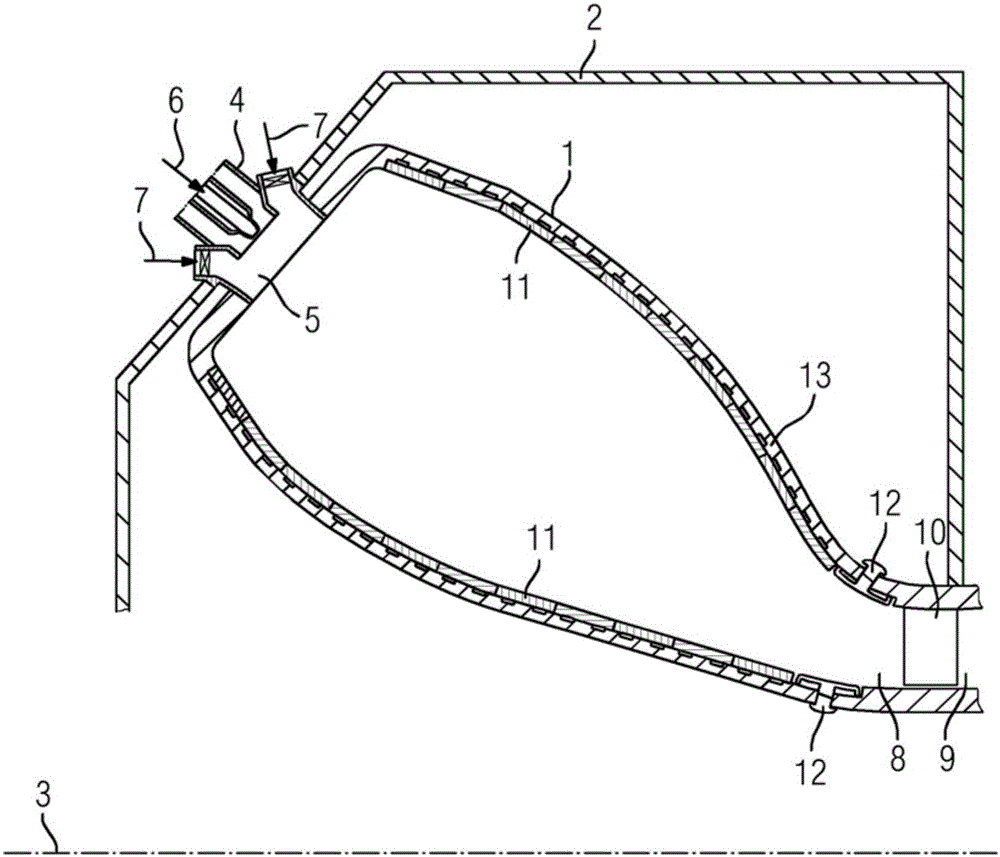

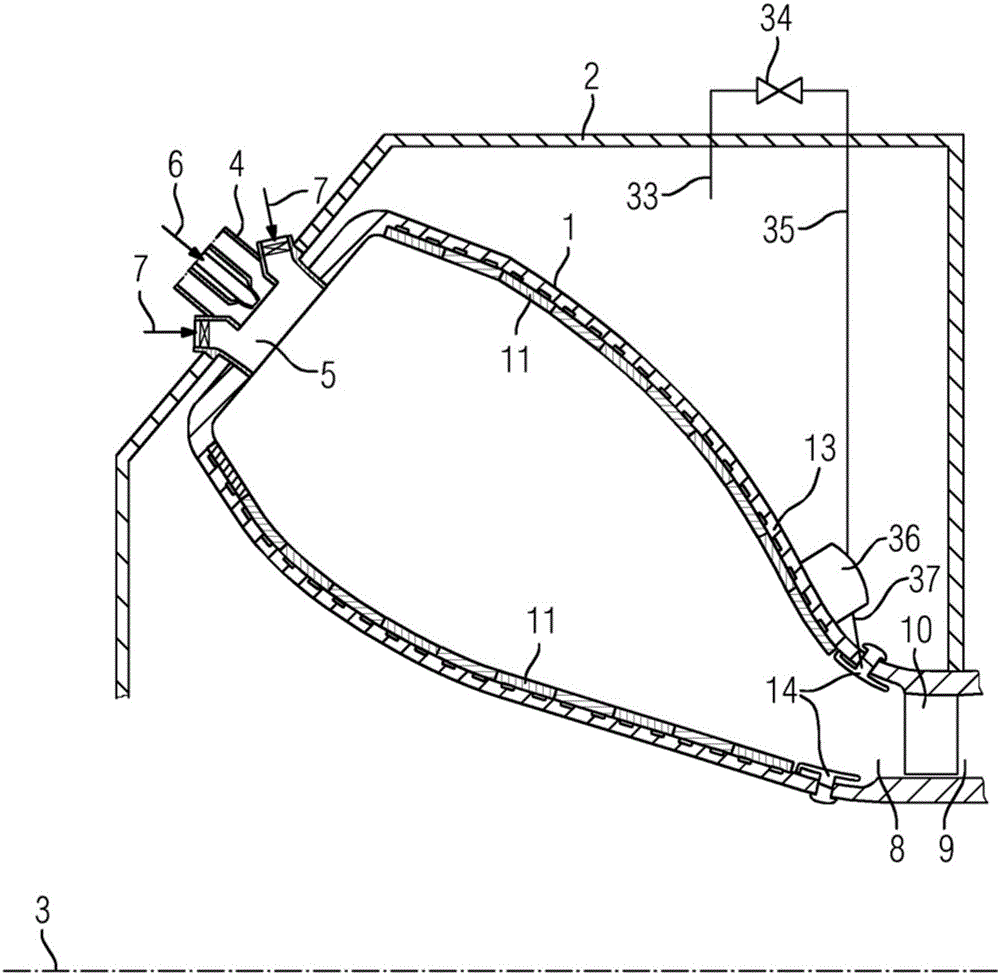

[0026] figure 1 The combustion system of an annular combustion chamber 1 according to the prior art is shown schematically and by way of example in a housing 2 . The annular combustion chamber 1 , which is formed as a closed ring, is arranged around the axis of rotation 3 . The burner 4 is arranged in the inlet 5 in the upper region of the combustion chamber 1 . There, fuel 6 is mixed with compressed air 7 . Combustion itself takes place in the combustion chamber 1 . The hot combustion gases enter the turbine 9 through an outlet at the turbine-side end of the annular combustion chamber 1 , where they come into contact with the first blades 10 . For protection prior to ignition, the annular combustion chamber 1 is lined with ceramic heat shield elements 11 and metal heat shield elements 12 , which are fastened to the combustion chamber wall 13 .

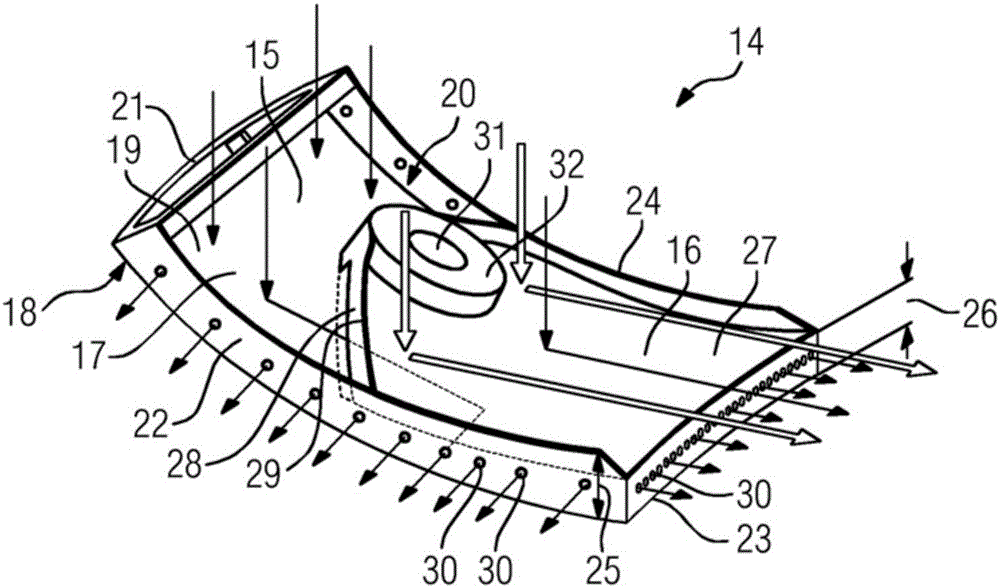

[0027] According to the invention, the introduction of the bypass air should be carried out in the region of the metal heat shie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com