Transparent low-colour lithium aluminium silicate glass ceramic and the use thereof

A glass-ceramic, transparent technology, applied in the field of LAS glass-ceramic, low-color lithium aluminosilicate glass-ceramic, can solve the problem of not providing devitrification resistance and transparency, and achieve low melting and forming temperature, devitrification resistance The effect of short sex and high light transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0136] The invention will be elucidated based on the following examples.

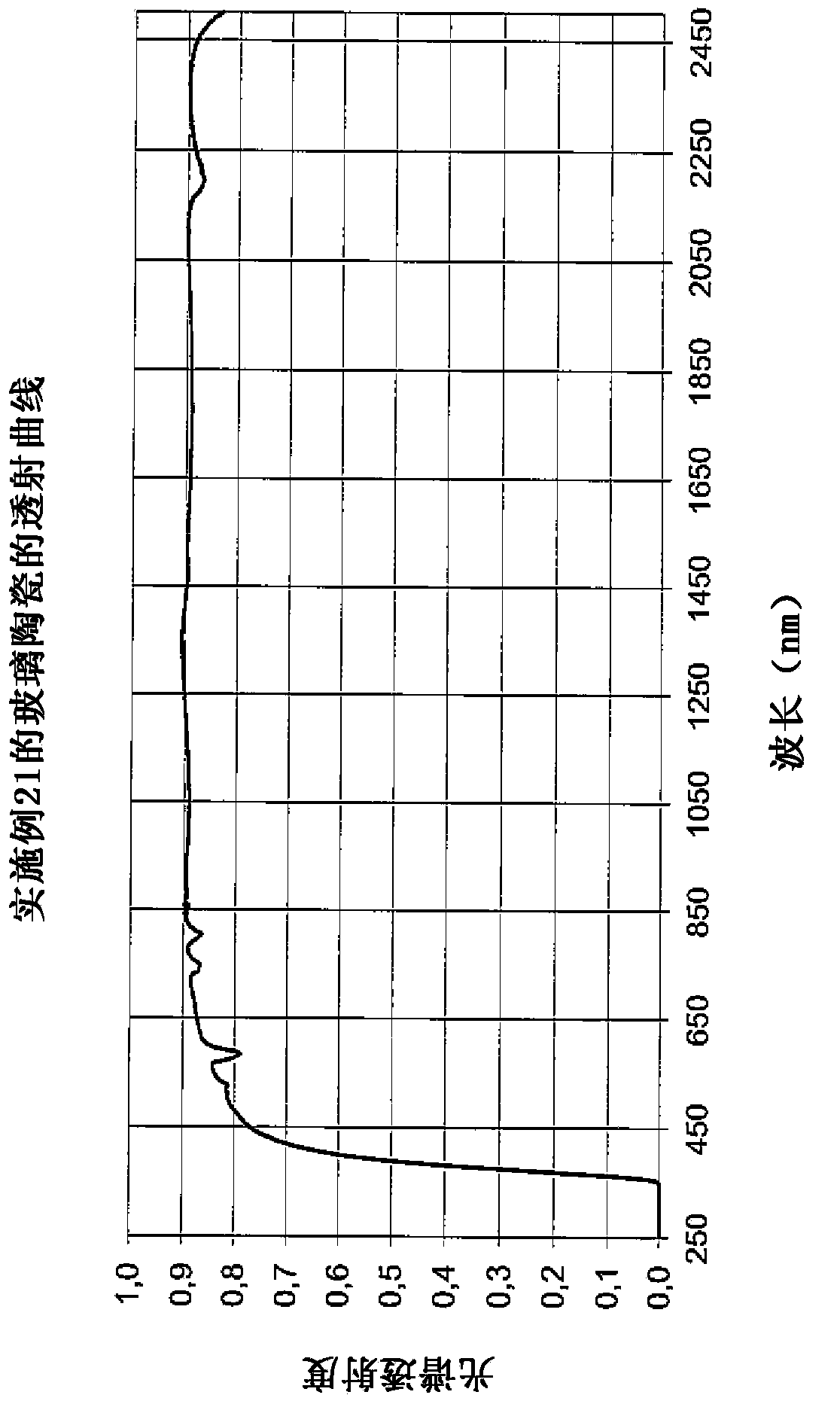

[0137] The transmission curve of the glass-ceramic of Example 21 is shown in a single figure.

[0138] Starting glasses from common raw materials in the glass industry were melted at a temperature of about 1620° C. for 4 hours. After melting the batch in a sintered quartz glass crucible, the melt was cast into a Pt / Rh crucible with an inner quartz glass crucible and homogenized at a temperature of 1550° C. for 30 minutes with stirring. After this homogenization, the glass was refined at 1640° C. for 2 hours. Subsequently, cast about 140×140×30mm 3 size and cool it down to room temperature in a cooling oven starting from 660 °C. Divide the casting into the dimensions required for research and for ceramization.

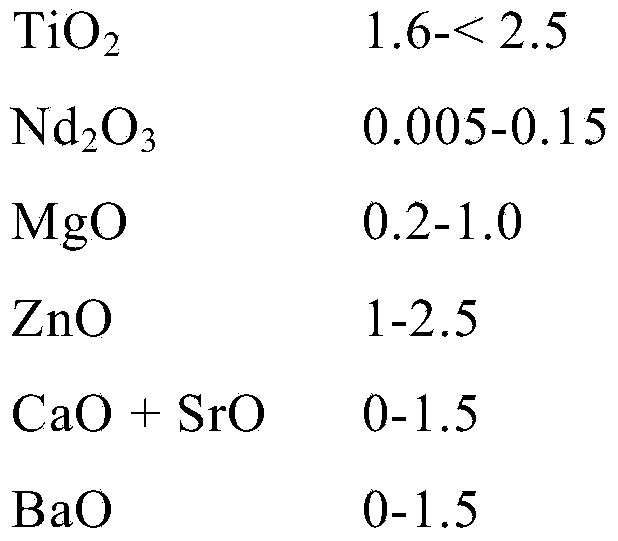

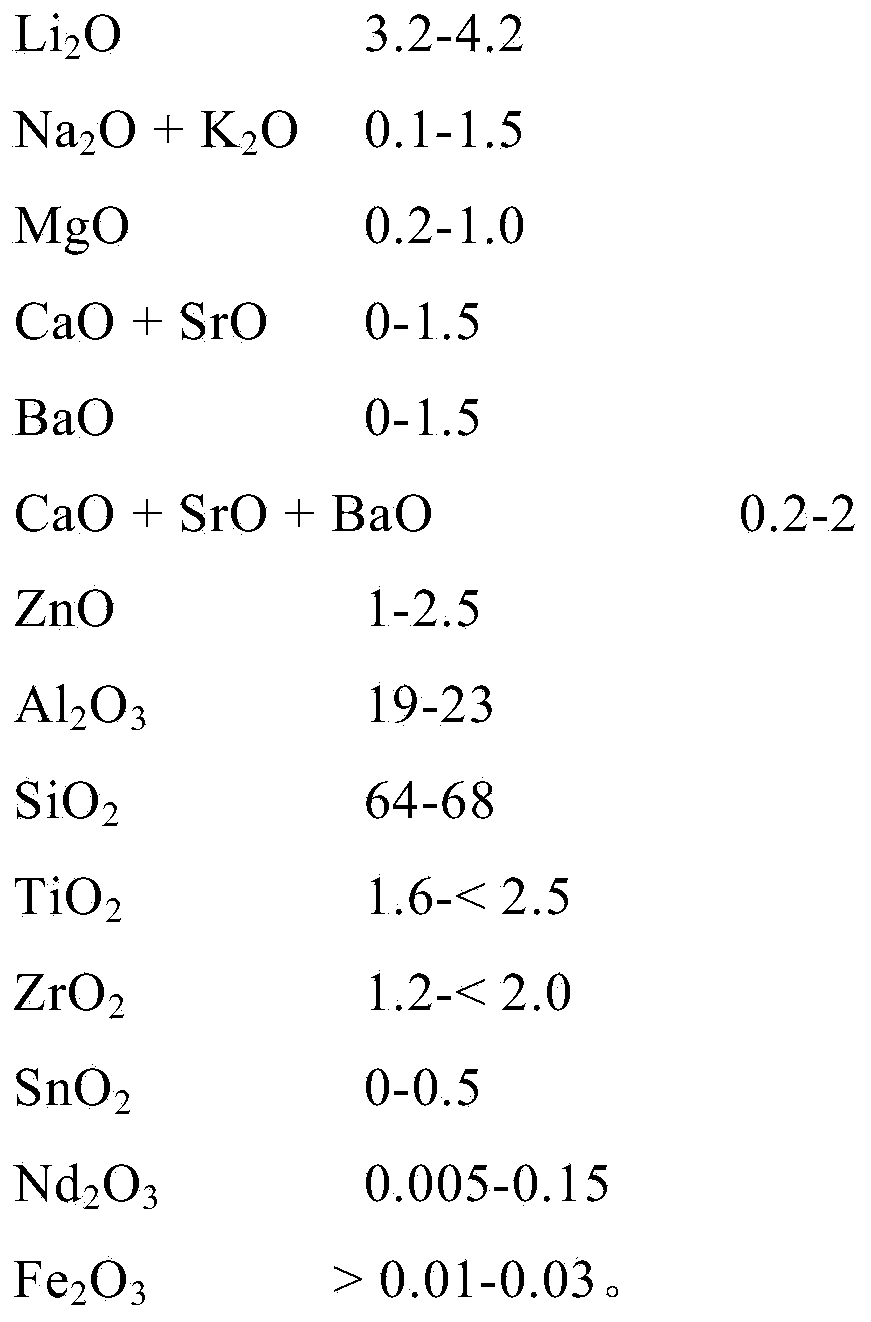

[0139] Table 1 lists the compositions and properties of the crystallizable initial glasses of the transparent glass ceramics of several implementation examples. Glasses 1 to 8 relate to glas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| visible light transmittance | aaaaa | aaaaa |

| visible light transmittance | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com