Precision Peeler

A peeling machine, precise technology, applied in the direction of electrical components, disassembly/armoured cable equipment, circuits, etc., can solve the problems of large volume occupying production space, heavy handling and safety hazards, peeling size cannot be fool-proof, etc. Achieve the effects of improving the production environment, increasing product profits, and reducing machine costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

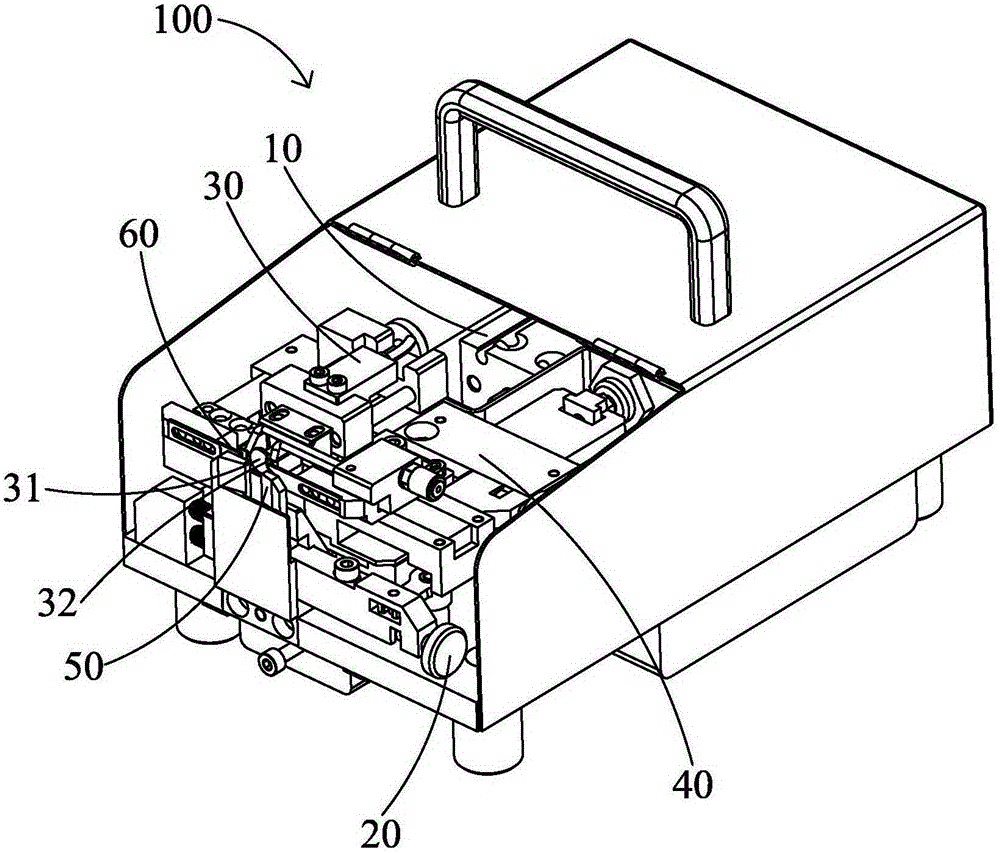

[0015] see figure 1 As shown, the precision peeling machine 100 of the present invention is used to peel the cables (not shown), which includes a cylinder 10, a screw adjustment knob 20, a precision photoelectric sensor 30, a double timing cam mechanism 40, and a cable positioning pressing block 50 and a pair of blades 60 spaced apart left and right.

[0016] The cylinder 10 is connected with the cam mechanism 40 via a floating joint. The cam mechanism 40, the cable positioning briquetting block 50 and the blade 60 are connected as a whole, the screw adjusting knob 20 is installed on the cam mechanism 40, the precision photoelectric sensor 30 is fixed above the screw adjusting knob 20, and a limit sensing PIN needle 31 and a limit sensor pin 31 are provided. Two fool-proof limit blocks 32 in front of the position sensing PIN needle 31, the limit sensing PIN pin 31 is used to control its induction and adjust the peeling size, and the blade 60 cuts off the cable sheath accordin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com