Wear-resistant 450 steel austenite grain size detection method

A technology of austenite grains and detection methods, applied in grain size analysis, measuring device, particle and sedimentation analysis, etc., can solve the problems of blurred grain boundaries, erosion of matrix structure, affecting the observation of austenite grain size, etc. , to achieve the effect of solving blurred grain boundaries, simple method and process, and promoting clarity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

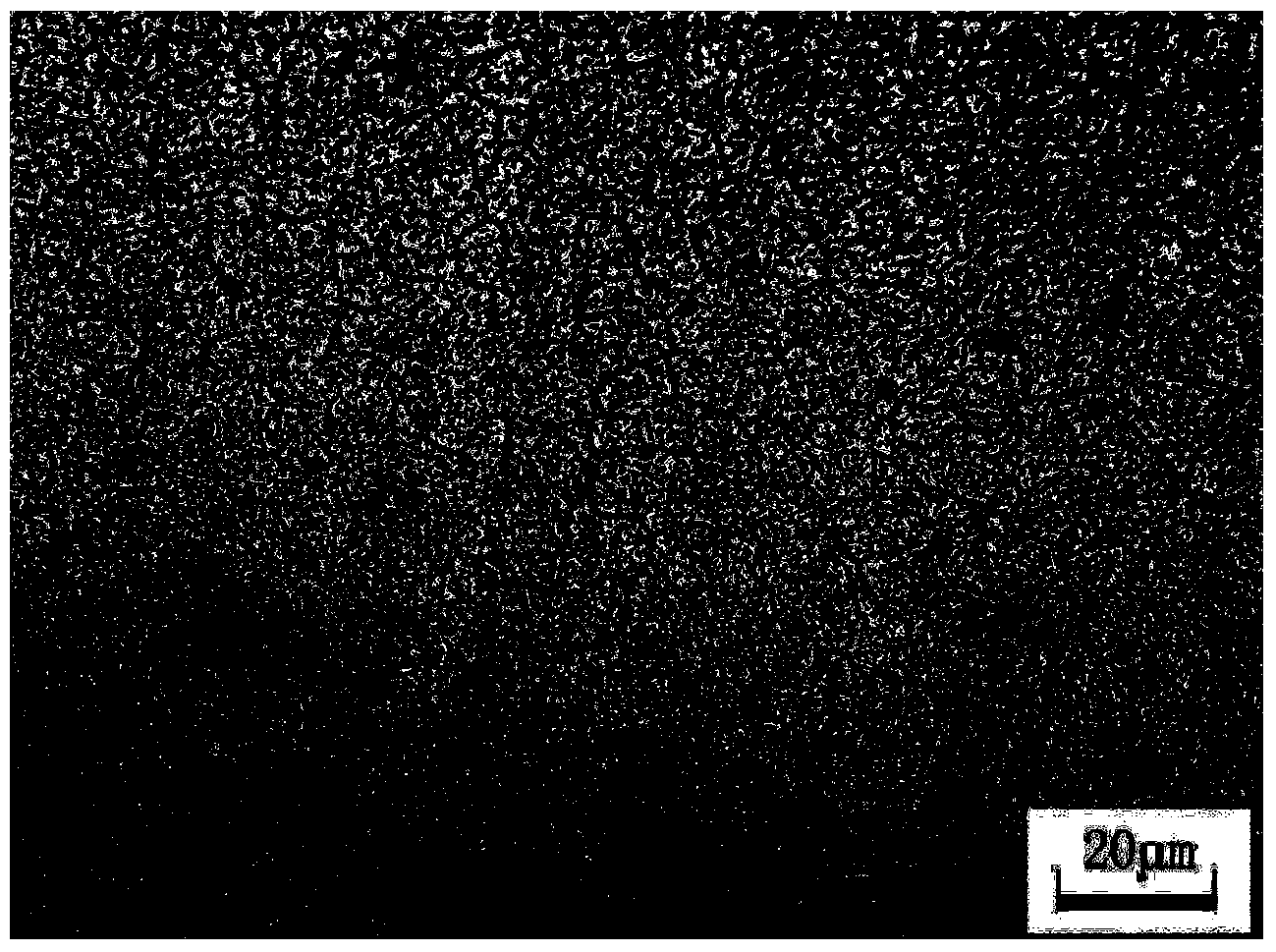

Image

Examples

Embodiment 1

[0029] The chemical composition and weight content of wear-resistant 450 steel are: C: 0.23%, Si: 0.42%, Mn: 1.53%, Cr: 0.52%, Mo: 0.32%, B: 0.002%, Ti: 0.05%, S: 0.005%, P: 0.007%, the rest is Fe and unavoidable impurities.

[0030] The method for detecting austenite grain size of wear-resistant 450 steel is carried out as follows:

[0031] 1) Take the 20mm wear-resistant 450 steel plate produced in large-scale production and cut the steel plate into small cubes with side lengths of 18-22mm, preferably processed and cut into 20×20×20mm squares to be tested. ;

[0032] 2) Quenching treatment: Put the samples into the heat treatment furnace in batches, so that the samples are in the middle of the furnace space, to ensure that the temperature near the samples is the same as the temperature detected by the thermocouple, and the samples are heated to 800 ℃~1000℃, preferably 850℃~900℃, holding time: 20-60 minutes, preferably 30-50 minutes, the quenching temperature of the 4 samples to b...

Embodiment 2

[0037] The chemical composition and weight content of wear-resistant 450 steel are: C: 0.26%, Si: 0.63%, Mn: 1.63%, Cr: 0.31%, Mo: 0.41%, B: 0.0015%, Ti: 0.06%, S: 0.004%, P: 0.008%, the rest is Fe and unavoidable impurities.

[0038] The method for detecting austenite grain size of wear-resistant 450 steel is carried out as follows:

[0039] 1) Take the 20mm wear-resistant 450 steel plate produced in large-scale production and process it into 4 pieces to be tested in a square shape of 20×20×20mm;

[0040] 2) Quenching treatment: Put the samples into the heat treatment furnace in batches, the quenching temperature is 900℃, and the holding time is 20min, 40min, 60min and 80min respectively. Observe the change of austenite grain size at different quenching temperatures. After that, use a clamp to pick up the sample and quickly take it out of the furnace. The sample is immediately quenched into the flowing water, and the test sample is taken out after it is completely cold. The cross-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com