Construction method for excavating water-rich shallow underground excavation tunnel

A shallow buried excavation and construction method technology, which is applied in the direction of tunnels, tunnel linings, earthwork drilling and mining, etc., can solve the problem of unfavorable control of tunnel settlement, horizontal convergence, and road settlement, and cannot ensure the safety of tunnel construction and road driving. Tunnel construction safety and other issues, to achieve the effect of improving mechanical utilization, short construction period and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

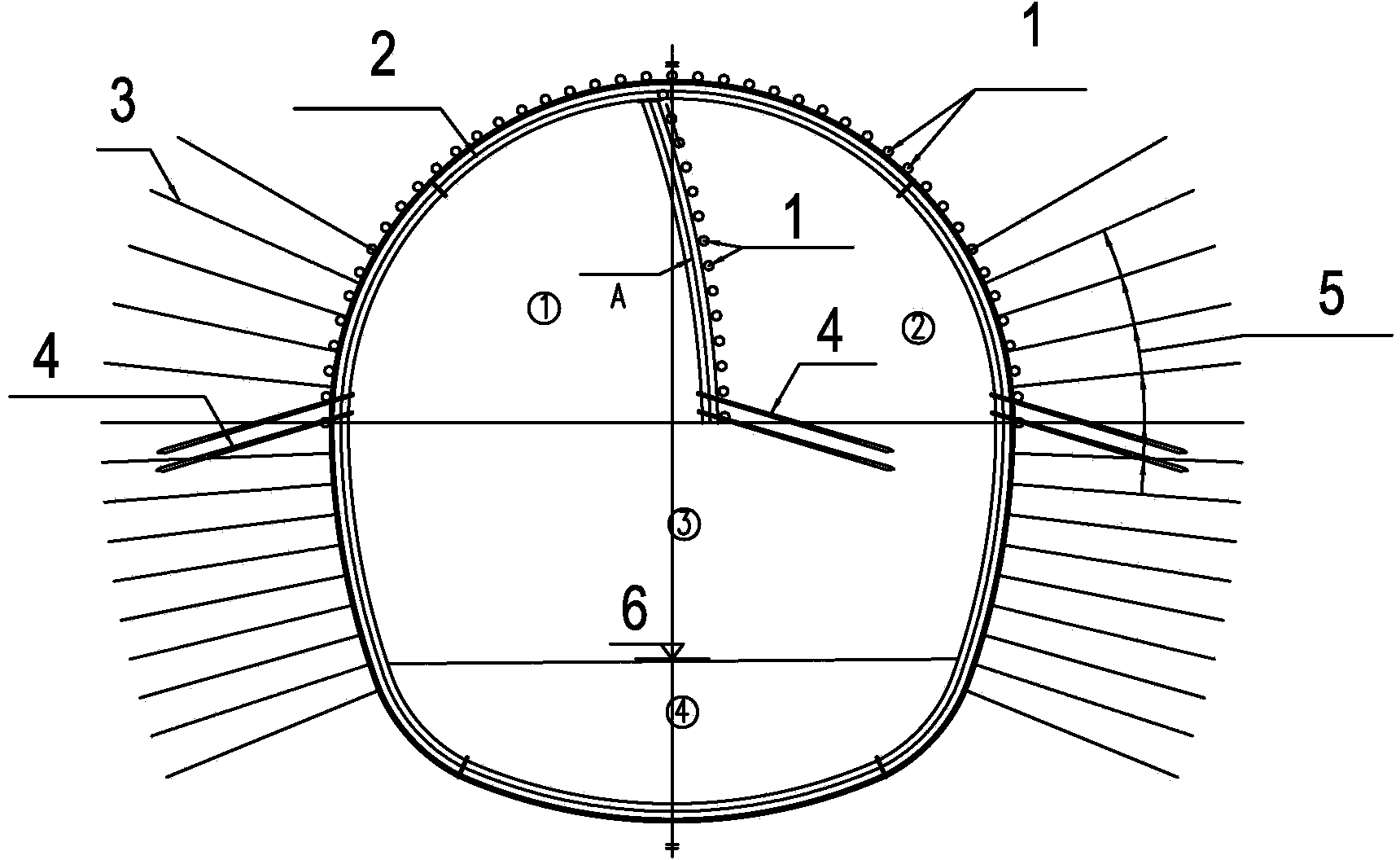

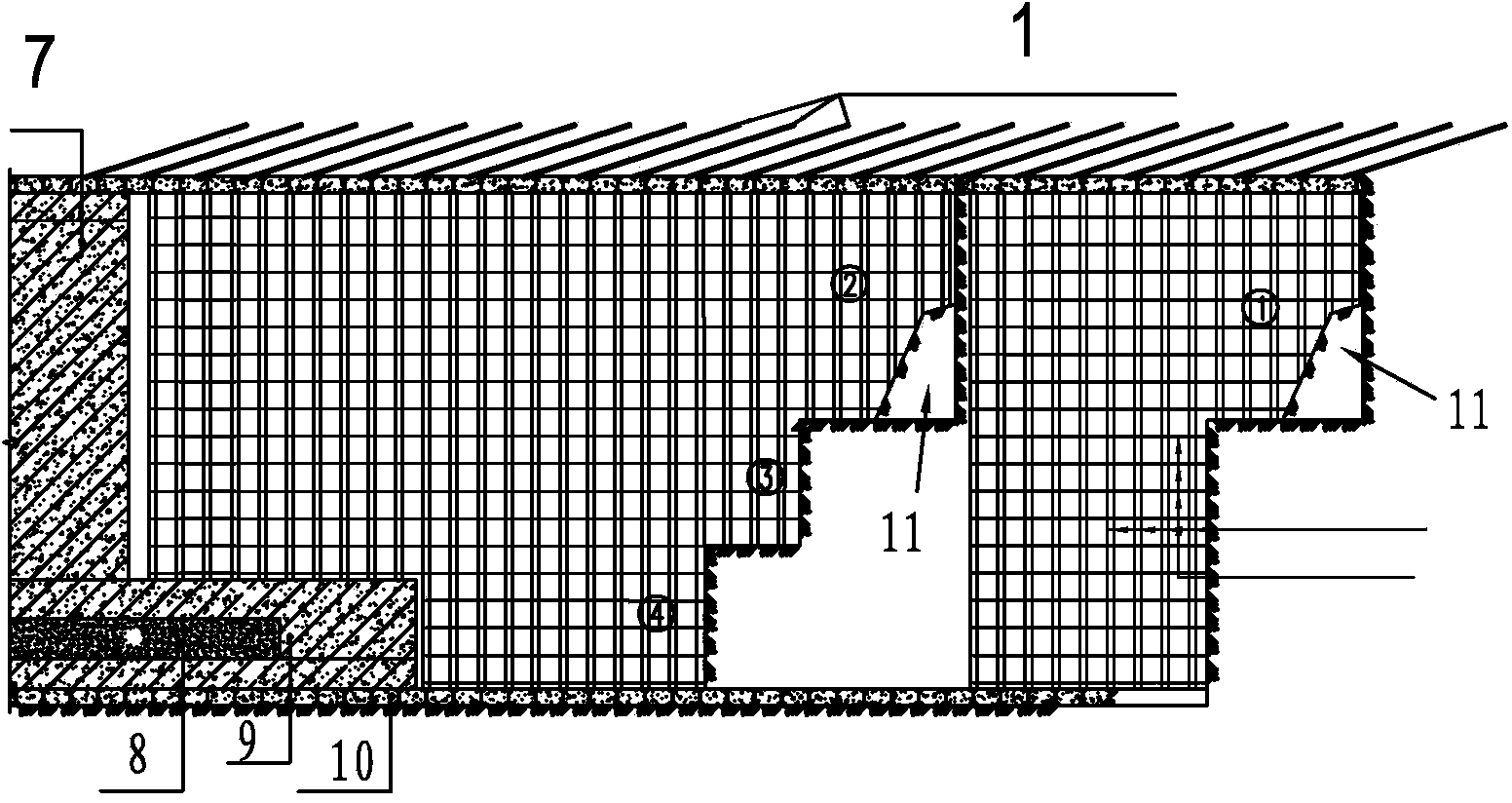

[0020] see figure 1 and figure 2 , the present invention divides the tunnel into four parts, ①, ②, ③, ④ parts. Among them, parts ① and ② are located in the upper part of the tunnel, part ③ is located in the middle of the tunnel, part ④ is located in the bottom of the tunnel, and parts ① and ② in the upper part of the tunnel are generally bounded by the vertical centerline of the tunnel.

[0021] The implementation methods include: 1) Use the steel frame erected in the previous cycle to construct the Φ42 advanced small conduit 1 within the 180° range of the tunnel arch and the side wall of the upper pilot pit, and carry out advanced grouting support; excavate part ①; For the initial support and temporary support around the pilot pit at the ① part, that is, the initial spraying of 4cm thick concrete, the installation of reinforcement mesh, the formation of the initial support reinforcement mesh and spraying 2, and the erection of steel frames and temporary support as the rock ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com