Horizontal reinforced concrete underground barn

A reinforced concrete and underground granary technology, applied in climate change adaptation, building type, construction, etc., can solve the problems of poor waterproof performance, small underground granary storage capacity, low strength, etc., and achieve easy anti-floating and waterproof treatment, storage capacity Large size and good grain storage performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with accompanying drawing and example.

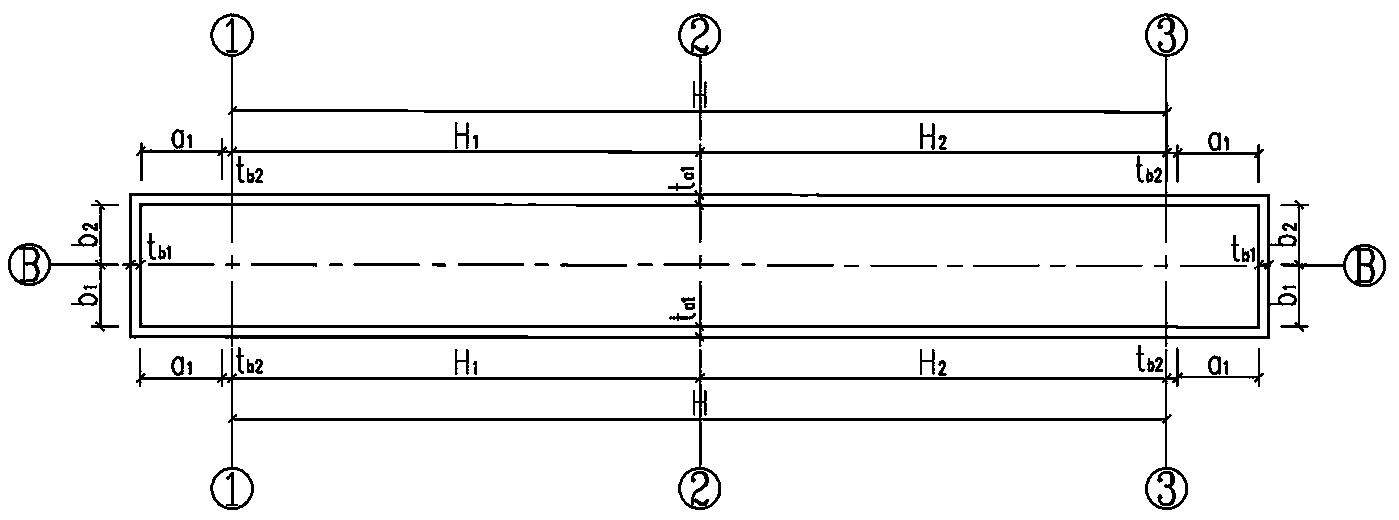

[0040] As shown in the accompanying drawings, the present invention is a horizontally arranged cylindrical reinforced concrete bulk grain underground silo with a horizontal conveying channel and a vertical conveying channel, including a middle silo wall (1), an end silo wall (2) and a silo wall ring. Grain storage space composed of beams (3), grain inlet at the top of the warehouse (6), grain outlet at the bottom of the warehouse (7), horizontal conveying channel (4), vertical conveying channel (5), and grain outlet at the top of the warehouse (8) Composed of grain in and out channels, horizontal conveying equipment (9), vertical conveying equipment (10), grain conveying equipment composed of bulk grain vehicles (12) and mobile belt conveyors (13), and grain conditioners installed on the inner surface of the warehouse wall Detection equipment (11).

[0041] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com