A B07 grade autoclaved sand aerated concrete block prepared by adding saponin air-entraining agent

A technology of saponin-based air-entraining agent and air-entrained concrete, which is applied in the field of environment-friendly fine chemical materials and green environmental protection and energy-saving building materials, and can solve the problems of low slurry water-material mixing ratio, low qualified rate of block products, poor pouring stability, etc. , to achieve good sound absorption and sound insulation effects, large masonry strength utilization coefficient, and low production energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

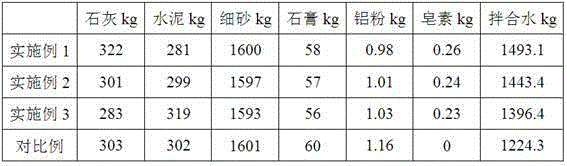

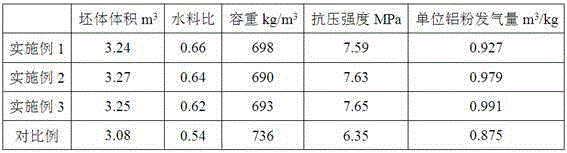

Embodiment 1

[0039] According to the formula in Table 1, each raw material was quantitatively weighed, first poured into the pouring pool 1600kg of machine-made sand and weathered sand mixture, 58kg of gypsum and 1010kg of surface water, stirred evenly to form a mortar slurry, and then poured in 322kg of lime, 281kg of cement and the rest Mix water in a certain amount, stir for a certain time, control the slurry temperature, when the temperature is ≥38°C, add water-soluble aluminum powder paste (0.98kg as aluminum) and air-entraining agent water (0.26kg as saponin) to form Stir for a certain amount of time to control the expansion of the slurry. When the expansion is ≥ 33cm, the inner volume of the slurry injection is 3.24m 3 After the pouring is completed, the mold is moved to the static parking room for maintenance for a certain period of time. After the green body meets the solidification requirements, it is moved out of the static parking room. After cutting and forming according to the...

Embodiment 2

[0042] According to the formula in Table 1, each raw material was quantitatively weighed, first poured into the pouring pool 1597kg of river sand, 57kg of gypsum and 1010kg of river water, stirred evenly to form a mortar slurry, then poured in 301kg of lime, 299kg of cement and the rest of mixing water, Stir for a certain time to control the temperature of the slurry. When the temperature is ≥38°C, pour 1.01kg of aluminum powder and air-entraining agent powder (0.24kg in terms of saponin) directly, and stir for a certain time to control the expansion of the slurry. The expansion is ≥ At 33cm, the inner volume of slurry injection is 3.24m 3 After the pouring is completed, the mold is moved to the static parking room for maintenance for a certain period of time. After the green body meets the solidification requirements, it is moved out of the static parking room. After cutting and forming according to the product specifications, the mold is freed, and the green body is moved to ...

Embodiment 3

[0045] According to the formula in Table 1, each raw material was quantitatively weighed, first poured into the pouring pool 1593kg of sea sand, 56kg of gypsum and 1010kg of seawater, stirred evenly to form a mortar slurry, then poured into 283kg of lime, 319kg of cement and the rest of mixing water, Stir for a certain time and control the slurry temperature. When the temperature is ≥38°C, add water-soluble aluminum powder paste (1.03kg as aluminum), air-entraining agent powder (0.23kg as saponin) and 1.8kg of water. Suspension, stir for some time to control the degree of expansion of the slurry, when the degree of expansion is ≥ 33cm, the inner volume of the slurry injection is 3.24m 3 After the pouring is completed, the mold is moved to the static parking room for maintenance for a certain period of time. After the green body meets the solidification requirements, it is moved out of the static parking room. After cutting and forming according to the product specifications, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com