Double-station rotary material fetching and placing mechanism

A double-station, pick-and-place material technology, applied in the direction of conveyor objects, transportation and packaging, packaging, etc., can solve the problems of obstacles to the development of automation equipment, low efficiency of film sticking, abnormal incoming materials, etc., and achieve low cost and convenient operation , the effect of improving practicality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with accompanying drawing.

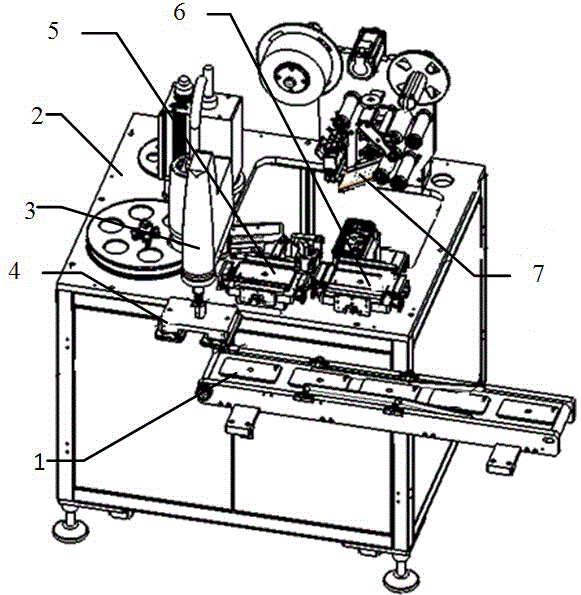

[0014] The double-station rotary picking and discharging mechanism includes a feeding belt 1, a machine table 2, a manipulator 3, a double-station suction cup 4, a positioning platform 5, a coating platform 6, and a shaping platform 7. It is characterized in that the manipulator 3, the positioning platform 5, The shaping platform 7 is set on the machine 2, the feeding belt 1 is set on one side of the machine 2, the coating platform 6 is set on the other side of the machine 2, and the double-station suction cup 4 is set on the manipulator 3 and moves with the manipulator 3 while moving. Manipulator 3 uses a four-axis robotic arm. The double-station sucker 4 adopts a vacuum sucker. The arrangement order of the manipulator 3, the positioning platform 5, and the shaping platform 7 on the machine platform 2 is the direction of travel of the feeding belt 1.

[0015] When the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com