Radiating type collector ring and application thereof

A collector ring and heat dissipation technology, which is applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problems of increased carbon brush wear, unfavorable oxide film, and high surface temperature of the collector ring, so as to prevent carbon deposition and strengthen dust removal effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings.

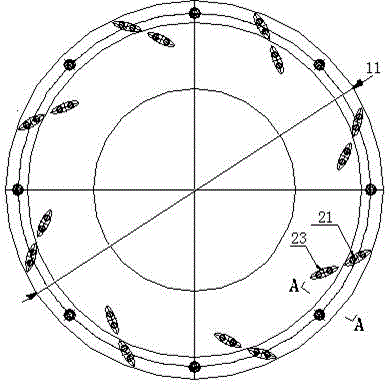

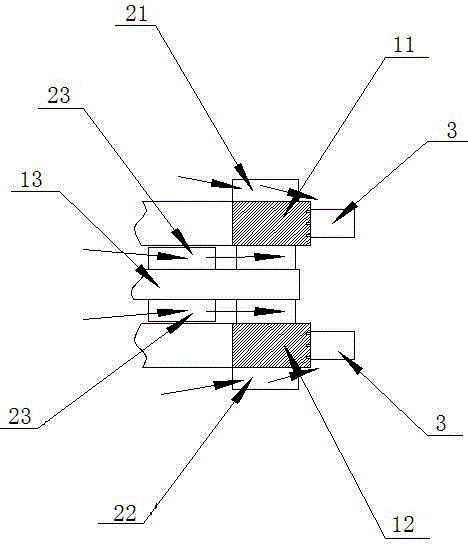

[0016] see figure 1 with figure 2 , a cooling type collector ring includes a collector ring body, the collector ring body includes an upper collector ring 11 and a lower collector ring 12, and a collector ring is provided between the upper collector ring 11 and the lower collector ring 12 Supporting plate 13, collector ring supporting plate 13 is matched with the lower surface of upper collector ring 11 and the upper surface of lower collector ring 12 respectively (that is, the upper surface of collector ring support plate has a gap with the lower surface of upper collector ring) gap, there is a gap between the lower surface of the collector ring support plate and the upper surface of the lower collector ring), the upper collector ring 11, the collector ring support plate 13 and the lower collector ring 12 are connected by a screw passing through the three ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com