Gas content desorption testing device

A measuring device and technology for gas content, which are applied in the field of petroleum exploration, can solve the problems of inability to use manual measurement, fail to realize automation, affect measurement results, etc., and achieve the effects of moderate volume, improved measurement efficiency, and accurate and reliable data.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but this does not constitute any limitation to the present invention.

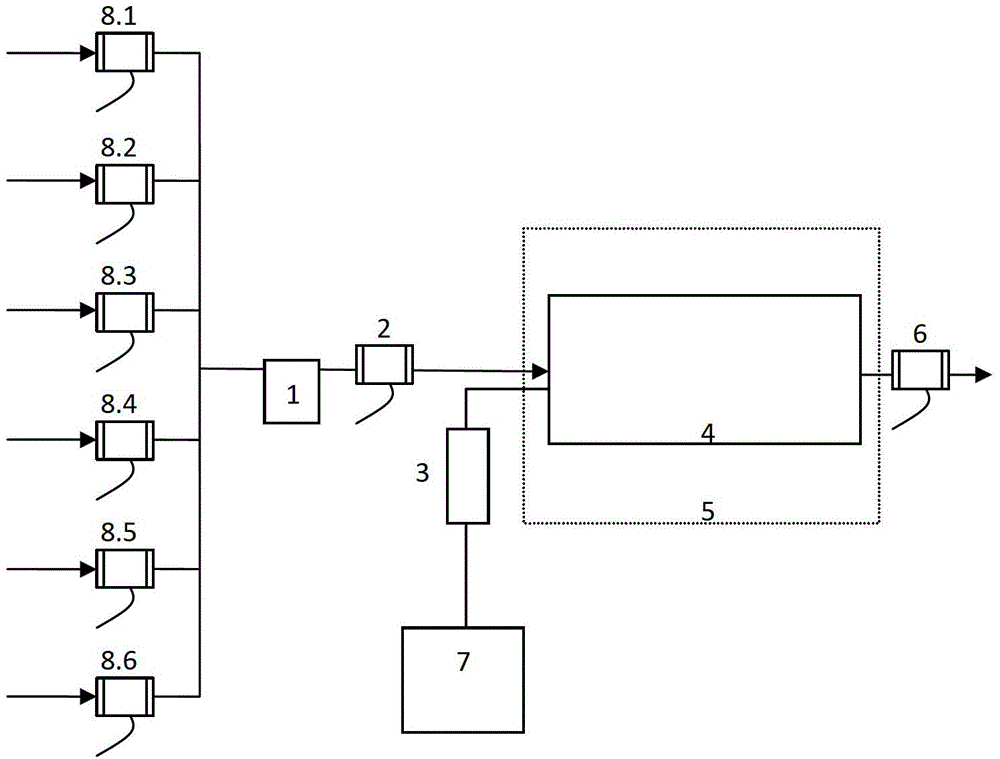

[0026] figure 1 A schematic diagram of an embodiment according to the invention is shown. In the figure, reference numerals 8.1-8.6 are first solenoid valves, which are respectively connected to different desorption gas sources. In a specific embodiment, the rock sample in the desorption tank is used as the desorption gas source. The first solenoid valves 8.1-8.6 are connected in parallel. The gas-water separation device 1 connected with the first electromagnetic valve 8.1-8.6. In a specific embodiment, the gas-water separation device 1 is a gas-water separator. The second solenoid valve 2 is connected with the gas-water separation device 1 . The second solenoid valve 2 is used for timing opening to allow gas to enter the container. The gas container 4 is connected with the seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com