A test method of engine tail jet pressure field

A test method and stress test technology, applied in the aviation field, to achieve the effects of cost reduction, wide applicability, and technical risk reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below through specific embodiments and in conjunction with the accompanying drawings.

[0032] This example is a twin-engine aircraft, using the free-flow contact pressure test system to test the pressure field of the engine tail jet. Specific steps are as follows:

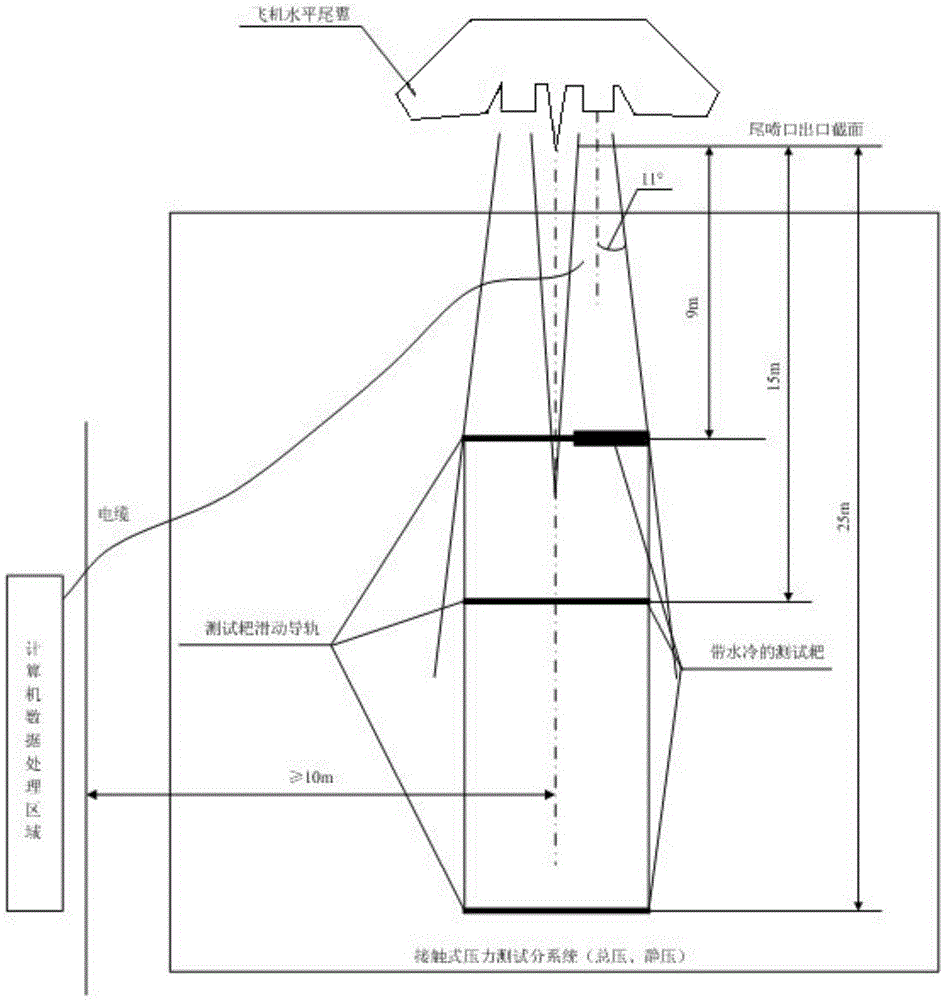

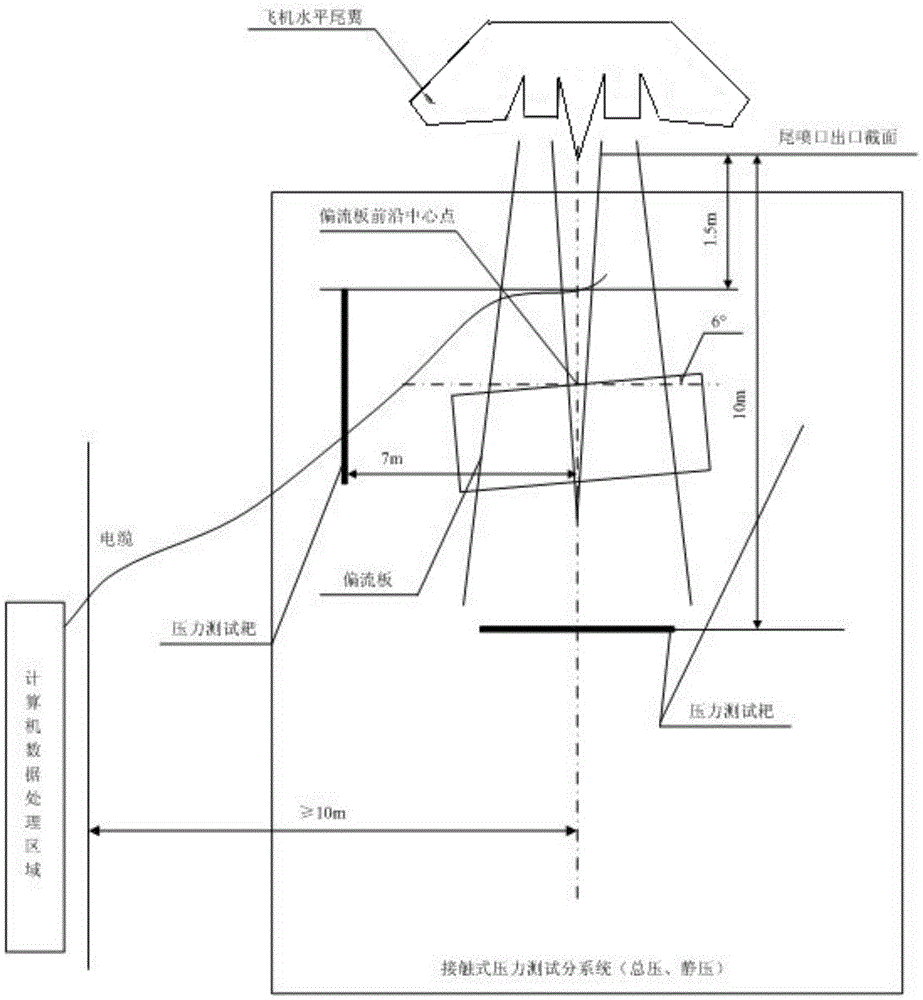

[0033] First, arrange the test system according to the free flow state: place three sets of pressure test rakes in parallel directly behind the engine tail nozzle, perpendicular to the tail nozzle axis, and respectively 9m, 15m, and 25m away from the engine tail nozzle section; , The data processing computer for the total pressure test is placed in a safe area;

[0034] Second, connect the test cables between the total pressure and static pressure test sensors and the data processing computer, power on the system for inspection, and complete the equipment debugging and preparation work before the test;

[0035] Thirdly, carry out the first phase of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com