Conductive film thickness measurement system based on eddy current sensor and method thereof

An eddy current sensor and thickness measurement technology, applied in the field of eddy current sensors, can solve the problems of complex signal processing, slow measurement speed, unreliability, etc., and achieve the effect of simple and clear relationship, simple information processing, and large measurement range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

[0059] The basic principles of the technical solution of the present invention are as follows:

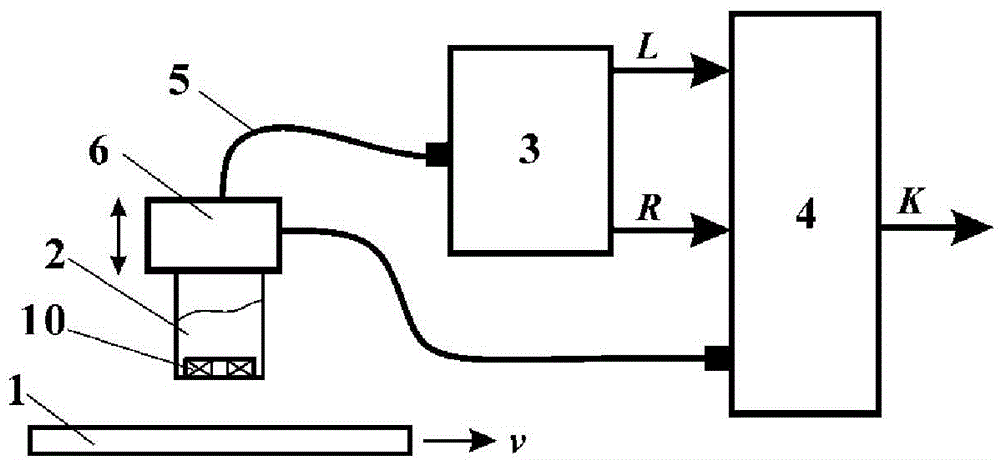

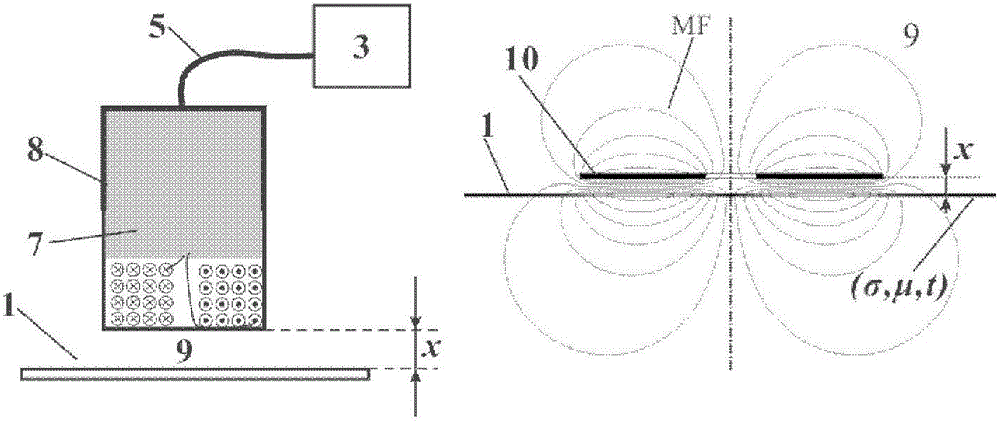

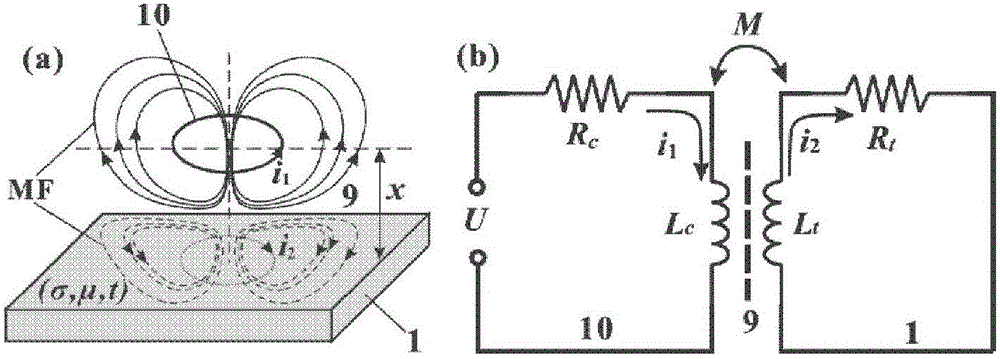

[0060] A disk-shaped air-core coil is used as the detection coil of the eddy current sensor, and is connected with the impedance measurement circuit through a coaxial line. The impedance measurement circuit applies a high-frequency alternating current to the detection coil, and at the same time can measure the variation of the real part (R) and the imaginary part (L) of the detection coil impedance with extremely high resolution.

[0061] When the distance x between the detection coil and the sample increases (or decreases), the impedance of the detection coil at different distances forms a curve at a series of points in the R...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com