Novel shale gas drilling machine

A technology for shale gas and drilling rigs, which is applied to rotary drilling rigs, drilling with liquid/gas jets, earthwork drilling and production, etc. It can solve problems such as easy to generate heat, cannot meet the use requirements, and affect the safety performance of drilling rigs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

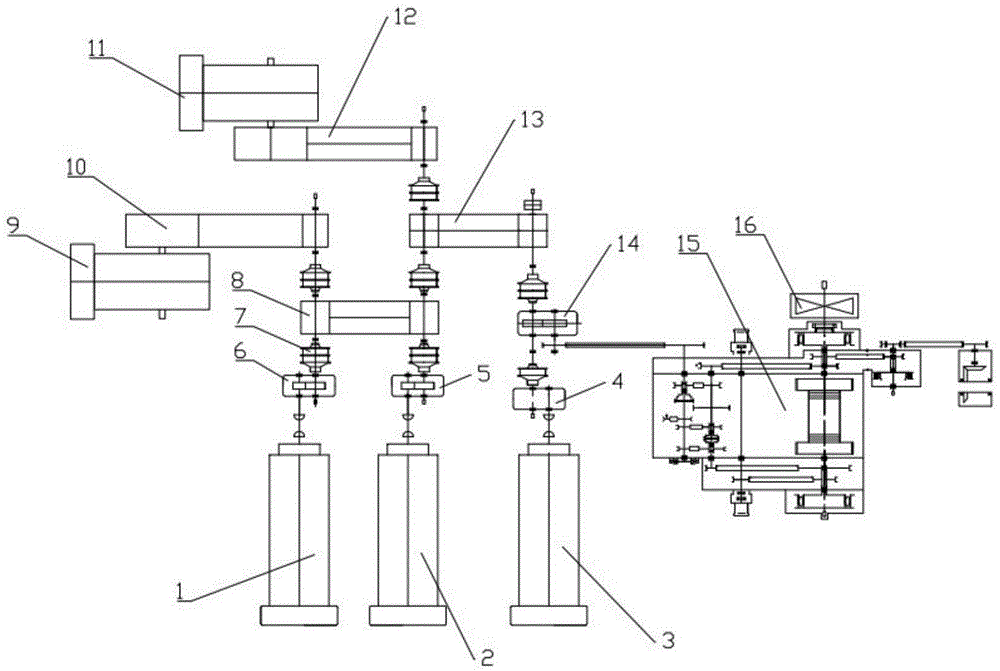

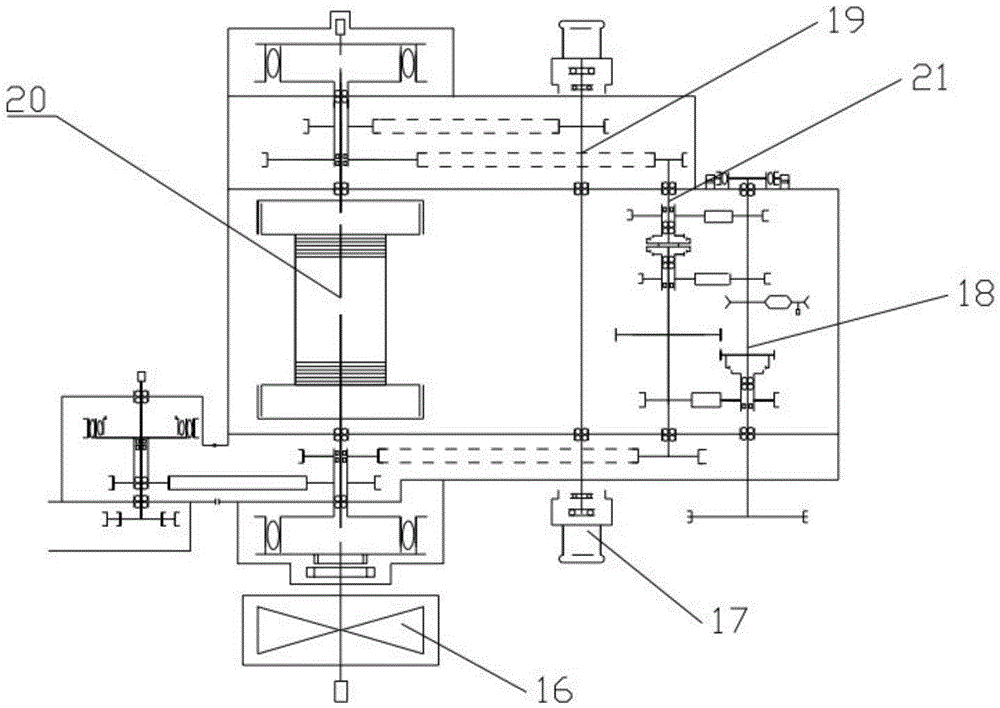

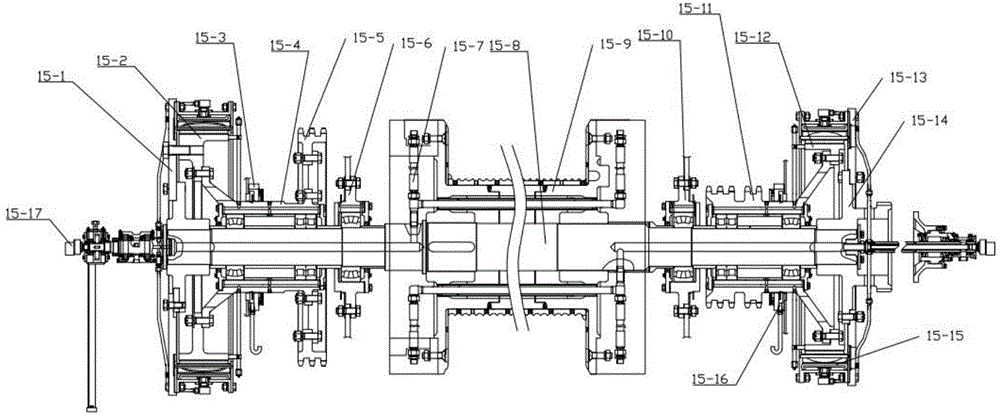

[0019] The present invention discloses such as figure 1 A new type of shale gas drilling rig shown includes a base, a derrick, a power unit, a transmission mechanism, a linkage mechanism, a turntable, and a drawworks 15 (see attached figure 2 ), traveling block, high-pressure pipeline, mud pump and air control system, the power plant includes three sets of diesel engines, and the three sets of diesel engines are respectively connected with the mud pump and winch 15 through linkage mechanism and transmission mechanism, and the winch 15 is an airtight water-cooled winch 15, the base includes a front base and a background base, the winch 15, the turntable and the turntable drive are arranged on the front base, and the power unit and linkage are arranged on the back base.

[0020] Described three cover diesel engines are respectively th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com