Construction method for prefabricated assembly type subway station

A subway station, prefabricated assembly technology, applied in the field of rail transit, can solve the problems of high safety risk, difficult quality, and only stop work, etc., and achieve the effect of easy widespread promotion, fast construction speed, and small surrounding impact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] The present invention will be further described below in conjunction with accompanying drawing:

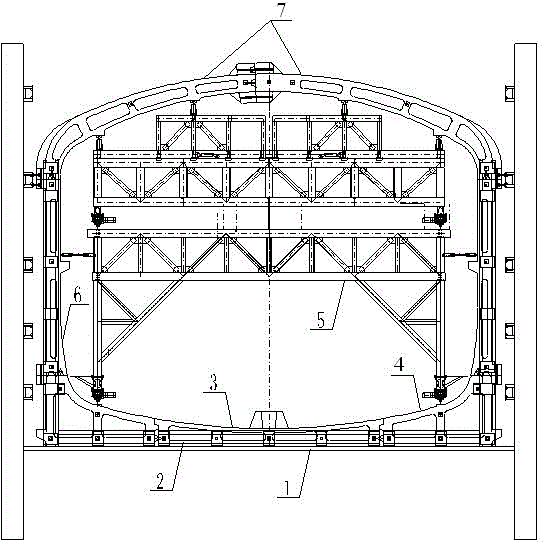

[0019] As shown in the figure, 1 is the cushion layer, 2 is the reaction frame, 3 is the prefabricated block of the bottom plate A, 4 is the prefabricated block of the bottom plate B, 5 is the assembly trolley, 6 is the side wall C prefabricated block, 7 is the top plate D and E prefabricated blocks.

[0020] Step ① Two sets of 75t gantry cranes are used for the lifting equipment, and assembled trolleys are used for the assembly equipment; Step ② Five concrete strips with a width of 1.8m are set for the cushion layer construction, and the accuracy is controlled within ±2mm; Step ③ The reaction frame and the first ring Reserve a gap of 8cm between them, and use steel plate welding to limit the first ring after installation; step ④The assembly process of block A of the first ring: measurement and lofting → hoisting in place → fine-tuning → the gap between the component and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com