A method of using white mud to prepare ultra-low density fracturing proppant

A fracturing proppant and ultra-low density technology, applied in the field of fracturing oil production, can solve the problems of high cost, poor temperature resistance, low proppant strength, etc., so as to reduce preparation cost, improve strength and temperature resistance, and increase utilization The effect of rate and added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

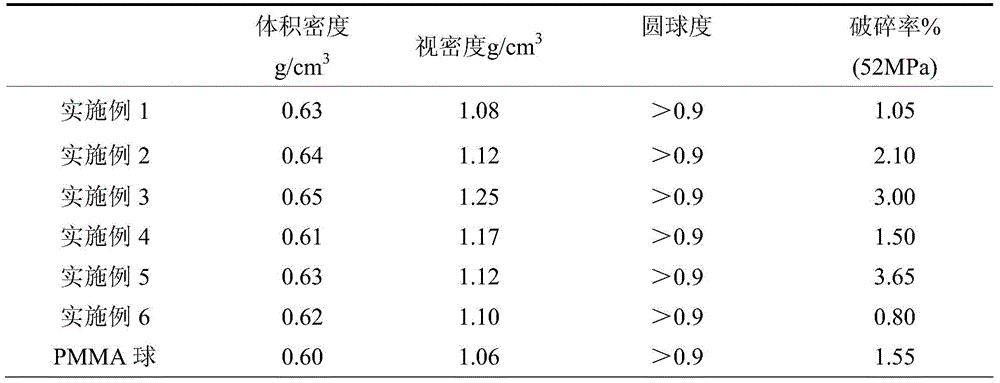

Examples

Embodiment 1

[0032] Modification of white clay:

[0033] Mix 100ml of toluene solution, 50g of white mud and 1g of KH570, raise the temperature of the water bath to 90°C and stir magnetically for 6 hours. After the reaction, wash once with toluene (the used toluene solution can be directly recovered and reused), and dry at 75°C. Get modified white clay.

[0034] Preparation of ultra-low density fracturing proppant:

[0035] Add 140ml distilled water, 10ml NaOH (2mol / L) solution and 10ml 1mol / LMgCl to the container 2 solution (reaction to obtain magnesium hydroxide dispersant), the temperature of the water bath was raised to 60 ° C and mechanically stirred, and 2 g of modified white mud was added immediately, and then 20 g of methyl methacrylate, 3 g of divinylbenzene (DVB), 0.35 g of initiator (BPO ) after stirring and mixing, drop it into the container, adjust the speed to 250r / min, raise the temperature to 80°C for 0.5h, 85°C for 1h, 90°C for 1h, stop the reaction and suction filter, w...

Embodiment 2

[0037] Modification of white clay:

[0038] Mix 100ml of toluene solution, 50g of white mud and 2g of KH550, raise the temperature of the water bath to 95°C and stir magnetically for 5 hours. After the reaction, wash once with toluene (the used toluene solution can be directly recovered and reused), and dry at 75°C. Get modified white clay.

[0039] Preparation of ultra-low density fracturing proppant:

[0040] Add 140ml distilled water, 10ml NaOH (2mol / L) solution and 10ml 1mol / L MgCl to the container 2 Solution, heat up the water bath to 60°C and mechanically stir, immediately add 4g of modified white mud, then stir and mix 20g of methyl methacrylate, 3g of DVB, and 0.35g of BPO, then drop them into the container, adjust the speed to 280r / min, and raise the temperature to 75°C React for 1 hour, react for 1 hour at 85°C, react for 1 hour at 90°C, stop the reaction and filter with suction, wash several times with distilled water, dry at 70°C, and pass through a 10-60 mesh si...

Embodiment 3

[0042] Modification of white clay:

[0043]Mix 100ml of toluene solution, 50g of white clay and 1g of KH570, raise the temperature of the water bath to 100°C and stir magnetically for 4 hours. After the reaction, wash once with toluene (the used toluene solution can be directly recovered and reused), and dry at 75°C. Get modified white clay.

[0044] Preparation of ultra-low density fracturing proppant:

[0045] Add 140ml distilled water, 10ml NaOH (2mol / L) solution and 10ml 1mol / L MgCl to the container 2 Solution, heat up the water bath to 60°C and stir mechanically, immediately add 6g of modified white mud, then stir and mix 20g of methyl methacrylate, 3g of DVB, and 0.35g of BPO, drop them into the container, adjust the speed to 300r / min, and raise the temperature to 80°C React for 1 hour, react for 2 hours at 85°C, react for 1 hour at 90°C, stop the reaction and filter with suction, wash several times with distilled water, dry at 70°C, and pass through a 10-60 mesh sieve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com