Airlift type integrated sewage treatment device

A sewage treatment device, air-lifting technology, applied in the field of air-lifting integrated sewage treatment device, can solve the problems that anaerobic microorganisms cannot play their role better, increase equipment cost and operating cost, and affect the effect of sewage treatment, etc. Achieve the effect of high sewage treatment efficiency, simple structure, and reduce dead angle of water flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

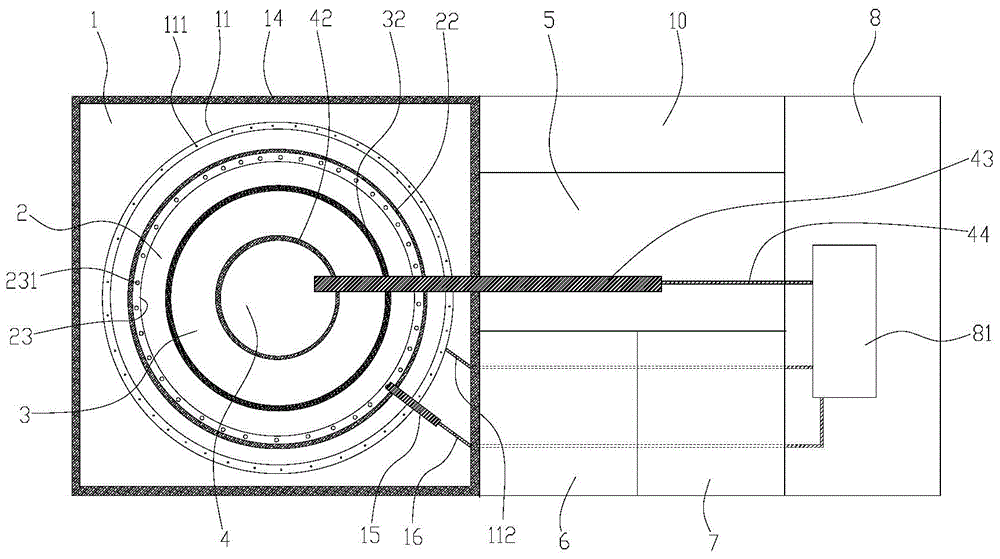

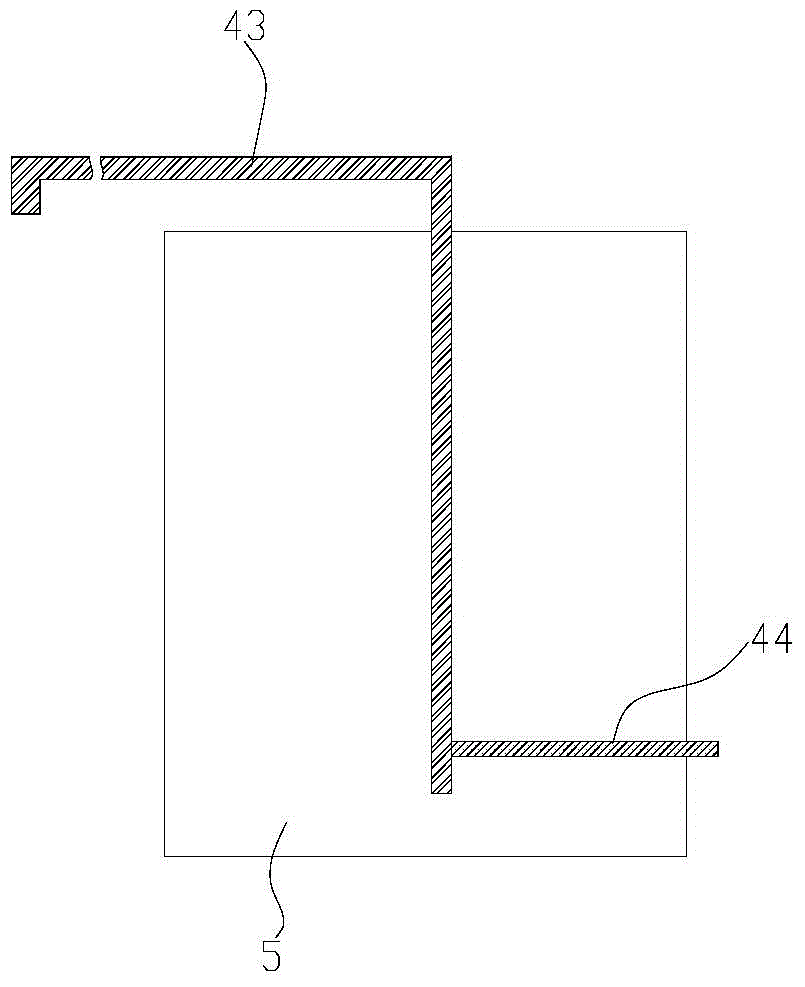

[0025] refer to Figure 1-7 , the air-lift integrated sewage treatment device provided in this embodiment includes a housing, a regulating tank 10, a pre-denitration tank 4, an anaerobic tank 3, an anoxic tank 2, an aerobic tank 1, a sedimentation tank 5, and a sludge tank 6 And clean water pool 7, and equipment control room 8. The regulating pool 10, the pre-denitration pool 4, the anaerobic pool 3, the anoxic pool 2, the aerobic pool 1, and the sedimentation pool 5 are arranged in the shell and communicated in sequence. The sludge tank 6 and the clean water tank 7 are also arranged in the shell, and communicate with the sedimentation tank 5 respectively.

[0026] The regulating tank 10 is provided with a water outlet and a water inlet, and a water inlet valve is arranged at the water inlet, and the water inlet is connected with an external sewage source through a pipeline. The sewage is subjected to conventional preliminary treatment, such as separating solid waste through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com