Triple-locking reel device

A technology of reel and cam, which is applied in the field of industrial detonating cord automatic coiling machines, can solve the problems such as insufficient arrangement, loose cord coils, and no adjustable tension device.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

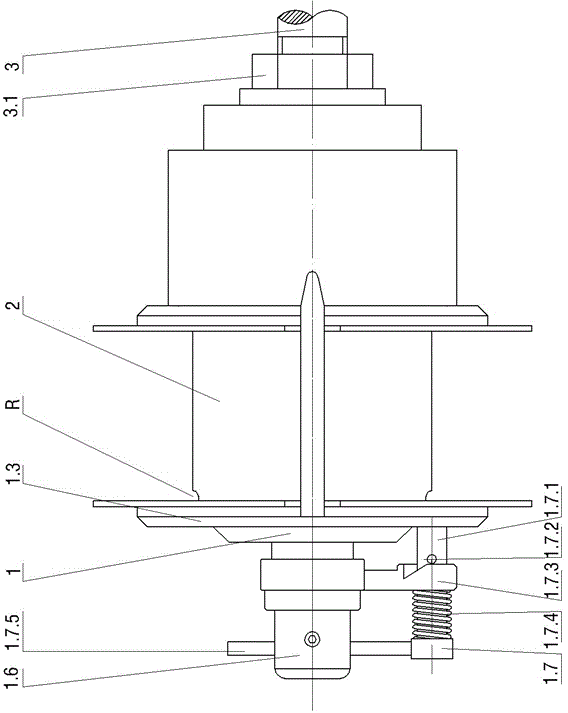

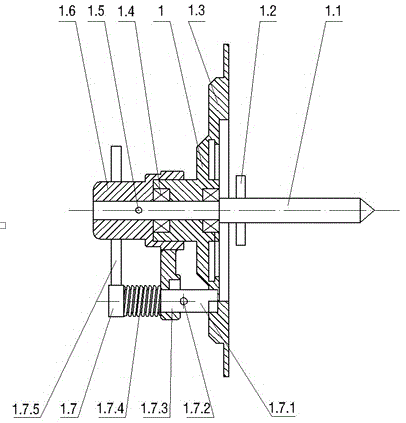

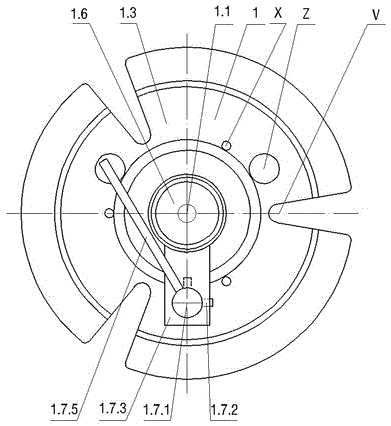

[0032] The present invention will be further described by using the drawings and examples.

[0033] The three-lock reel device of the present invention includes a reel cover 1 and a reel base 2, and the reel cover 1 includes a central shaft 1.1, a transverse round pin 1.2, a round cover 1.3, a bearing 1.4, a fixed pin 1.5, Rotating cap 1.6, rotating handle 1.7, described rotating handle 1.7 includes rotating handle shaft 1.7.1, limit pin 1.7.2, rotating block 1.7.3, compression spring 1.7.4, rotating arm 1.7.5, first put the two Install a bearing 1.4 on the round cover 1.3, insert the horizontal round pin 1.2 into the central shaft 1.1 and fix it, install the small end of the central shaft 1.1 on the bearing 1.4, and make the rotating block 1.7.3 have an arc surface One end is welded together with the rotary cap 1.6, and the side of the rotary block 1.7.3 with the rotating downward spiral groove is aligned with the direction of the large inner hole of the rotary cap 1.6, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com