Dust-suppression sweeping system for material conveyor belt

A technology for conveying belts and cleaning systems, which is applied in the field of cleaning systems to save water resources and avoid cleaning workloads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

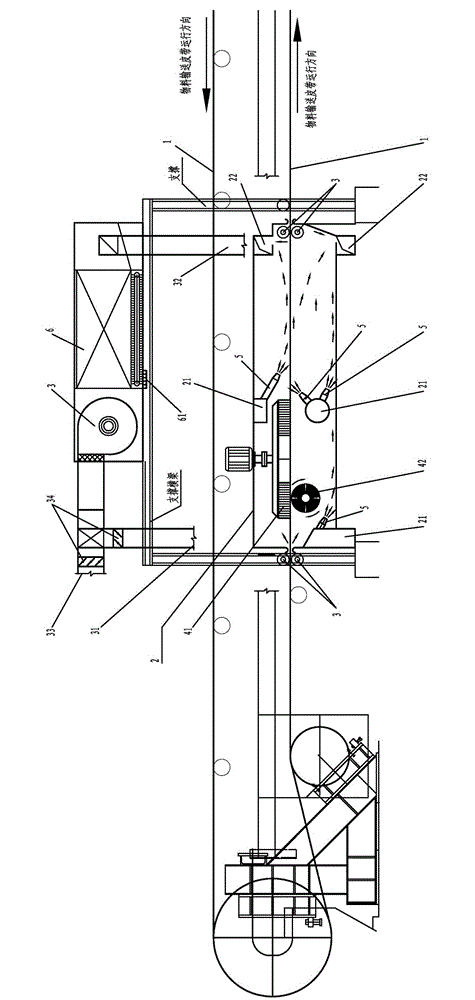

[0028] Such as figure 1 A kind of material conveying belt dust suppression cleaning system of the present invention shown, it comprises material conveying belt 1, and it is provided with cleaning shell 2, and this material conveying belt 1 passes through in this cleaning shell 1; Material conveying belt 1 enters The position of the cleaning housing 2 and the position away from the cleaning housing 2 can be provided with guide rollers 3 to facilitate the better operation of the material conveying belt.

[0029] The cleaning housing 2 is provided with a cleaning device for cleaning the material conveyor belt; the cleaning housing 2 is also provided with an air supply pipe 21 and a dust suction air pipe 22; the cleaning system is also provided with a fan 3, and the fan 3 passes through the first An air supply pipe 31 is connected with the air supply pipe 21, and the fan 3 is connected with the dust suction air pipe 22 through the second air supply pipe 32, and the air supply pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com