Combination of reinforced elastic cushioning material for hot pressing and laminate containing the combination of reinforced elastic cushioning material for hot pressing

A technology of elastic buffering and buffering materials, applied in the field of laminates, to prevent adhesion of steel plates, reduce production costs, and improve product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

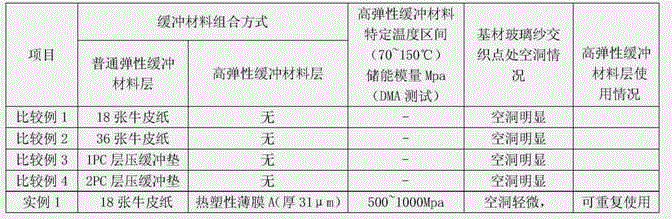

Examples

Embodiment Construction

[0021] refer to figure 1 , a laminated board, comprising a laminated support plate or cover plate layer 1, a high elastic buffer material layer 2, a common elastic buffer material layer or a high temperature resistant barrier material layer 3, a steel plate layer 4, and a product layer 5 to be laminated. The structure of the product layer 5 to be pressed is copper foil layer 51-adhesive sheet layer 52-copper foil layer 51, and both sides of the product layer 5 to be pressed are provided with steel plate layers 4, and the laminated board The layer 5 of the product to be laminated is composed of one or more layers and the steel plate layer 4 repeatedly at intervals. .The combined mode of the reinforced elastic buffer material can be followed by ordinary elastic buffer material layer or high temperature resistant barrier material layer 3, high elastic buffer material layer 2, ordinary elastic buffer material layer or high temperature resistant barrier material layer combination 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| storage modulus | aaaaa | aaaaa |

| storage modulus | aaaaa | aaaaa |

| storage modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com