Ceramic pugmill

A technology of mud refining machine and ceramics, which is applied to clay preparation devices, chemical instruments and methods, clay processing equipment, etc., can solve the problems of reduced production efficiency, inconvenient handling, and difficult disassembly and cleaning of sieve plates, so as to meet production requirements. desired effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with specific embodiments.

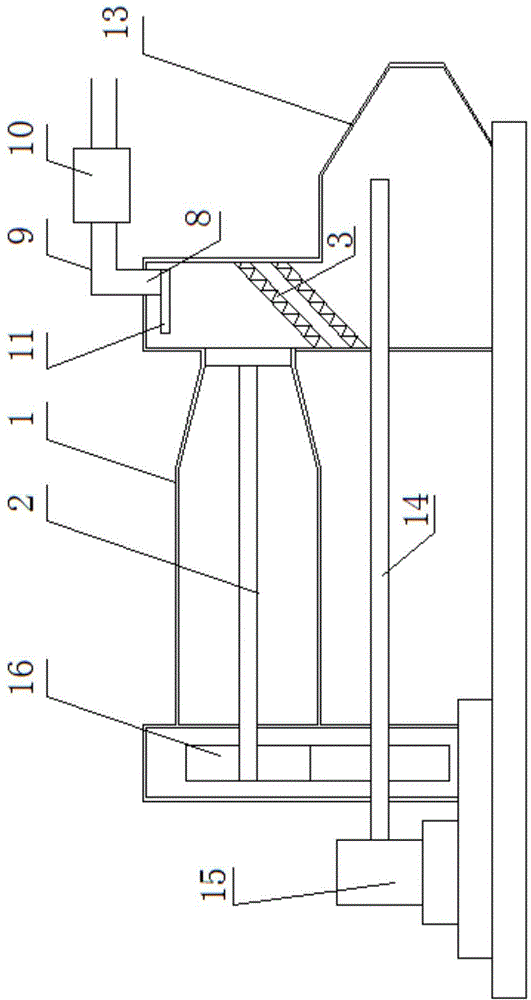

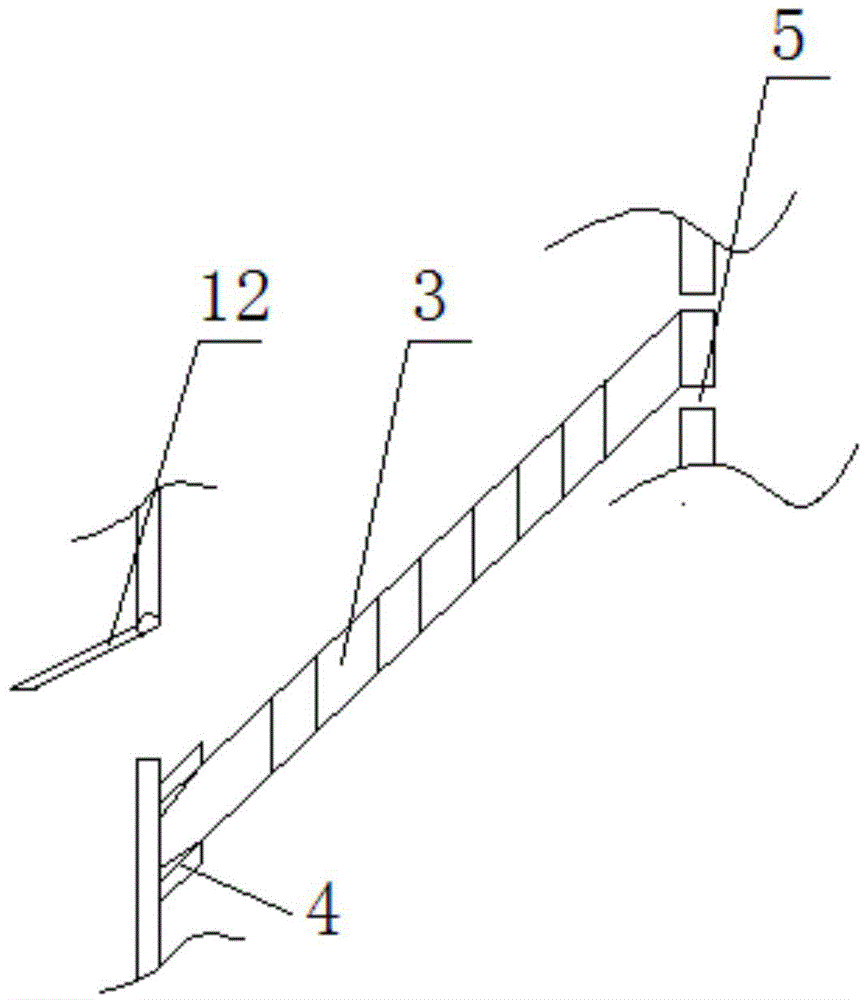

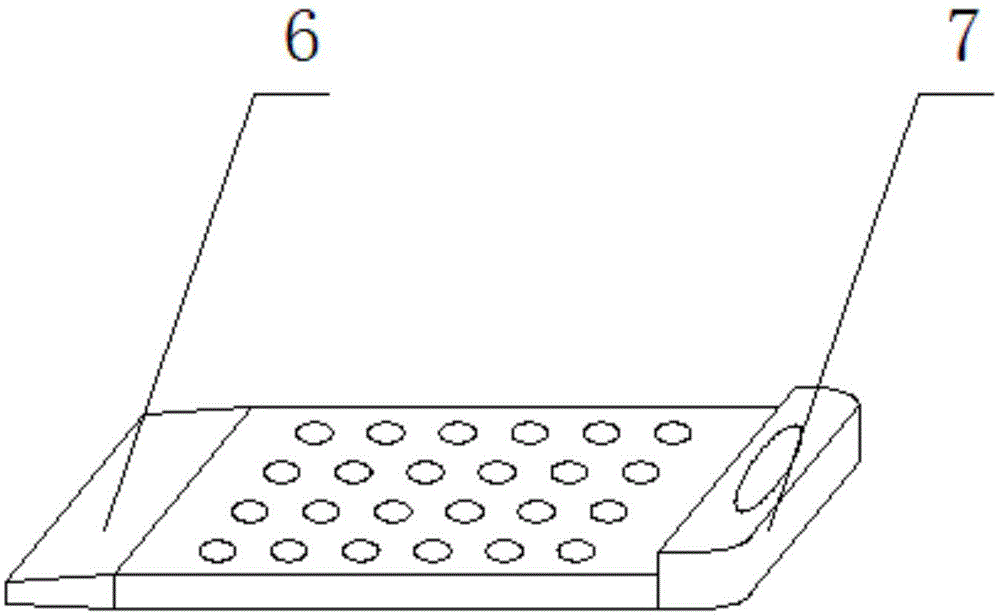

[0017] Such as figure 1 , figure 2 and image 3 A kind of ceramic clay refining machine of the invention as shown, comprises charging box 1, and first roller 2 is arranged in described charging box 1; The charging box 1 box body behind described first roller 2 is provided with filtering device, The filtering device includes several sieve plates 3, slots 4 arranged on one side of the side wall of the feed box 1 and protruding holes 5 arranged on the other side of the feed box 1, the sieve plates 3 are provided with sieve holes , in this embodiment, the slot 4 and the protruding hole 5 are not set at the same height, so that the sieve plate 3 is obliquely arranged in the feeding box 1, avoiding the blockage of the sieve plate 3; one part of the sieve plate 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com