A modular tandem master robot

A master robot and serial technology, applied in manipulators, program-controlled manipulators, joints, etc., can solve the problems that the master robot is difficult to adapt to the slave robot, cannot change the configuration, and lacks versatility, and achieves good versatility and flexibility. Simple construction and disassembly, easy and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to better understand the present invention, a five-degree-of-freedom main robot will be further described below in conjunction with the accompanying drawings, but the embodiments of the present invention are not limited thereto.

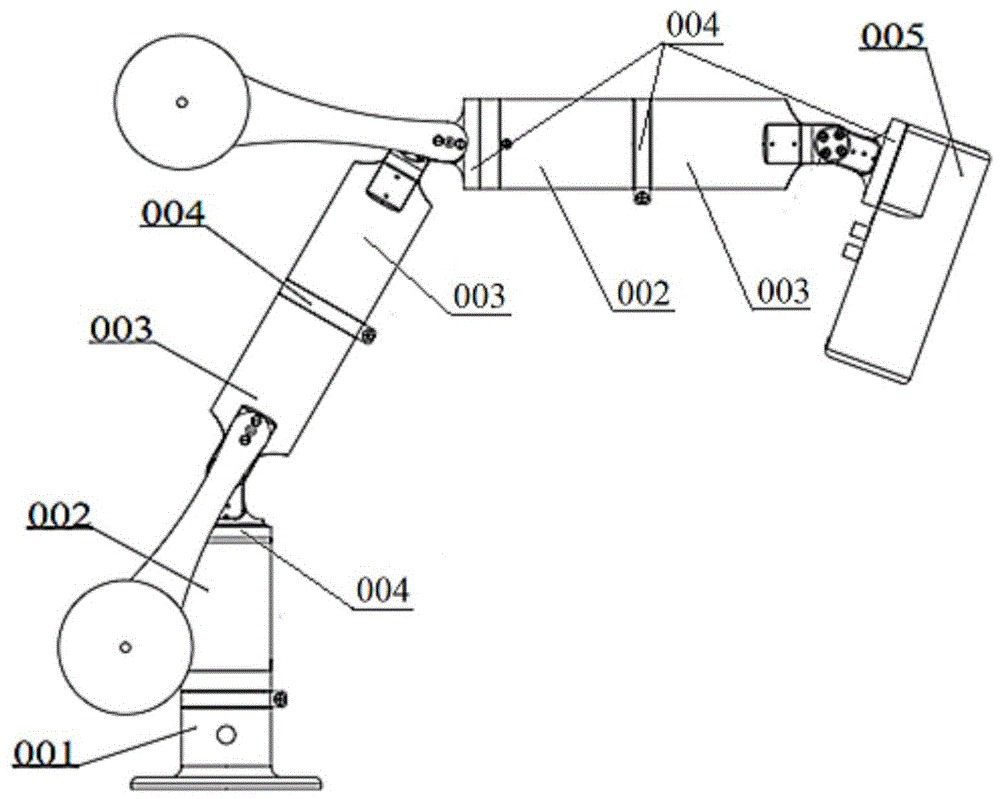

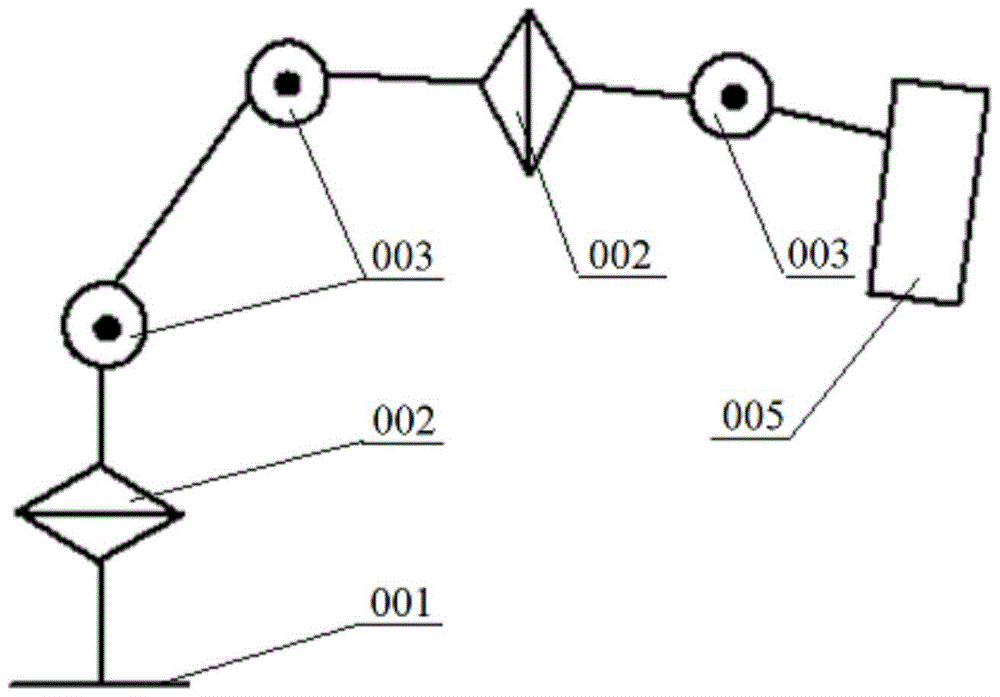

[0026] figure 1 with figure 2 The appearance diagram and schematic diagram of the mechanism of the five-degree-of-freedom series main robot constructed by the present invention are respectively shown. As shown in the figure, the modular main robot body includes a flange 001 as a base, three swing joint modules 003, two swing joint modules 002 and a handle module 005, and each module is connected in series in turn , the connection sequence from the base to the end is: flange, first swing joint module, first swing joint module, second swing joint module, second swing joint module, third swing joint module, handle module , the two are fastened through the snap ring 004, the base end is fixed on the console through the flange 001, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com