H-shaped steel welding pure mechanism wire feeding method and gantry type equipment

A gantry-type, H-shaped steel technology, applied in welding equipment, arc welding equipment, welding accessories, etc., can solve the problems of welding arm instability, excessive dependence on motors, and low overall efficiency, and meet the requirements of ensuring uniform wire feeding and welding The effect of quality and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

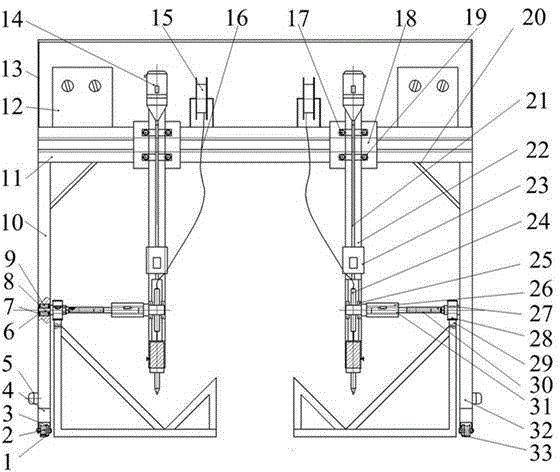

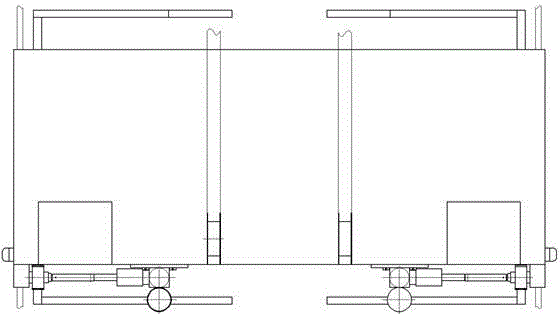

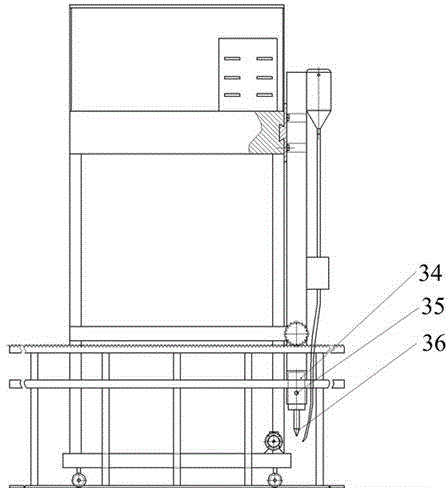

[0026] Such as figure 1 , figure 2 , image 3 As shown, the top of the gantry support 10 adopts a support steel pipe 13, the support beam 11 spans the two ends of the gantry support 10, two moving sliders 18 are installed on the support beam 11, and the track 1 and the driving wheel 3 are installed at the bottom of the support 4. A three-phase asynchronous motor 5 is installed on the upper end of the wheel 3 . The transmission system is installed on the gantry frame, that is, the sleeve shaft 26 and the stepped shaft 31, and the sleeve shaft 26 is installed in the welding arm 22. The gear shaft 27 is connected with the stepped shaft 31 through a sleeve coupling 30 , and the gear shaft 27 is installed on the gantry support 10 . Driven by the three-phase asynchronous motor 5 , the drive shaft 2 will drive the drive wheels 3 to move along the track 1 , and the gantry frame and the drive wheels 3 are connected into one body through the drive shaft 2 . Support crossbeam 11 has...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com