Layered high-frequency fine vibrating screen

A technology of high-frequency vibration and high-frequency sieve, applied in the direction of filter screen, solid separation, grid, etc., can solve the problems of inconvenient, low processing capacity, adjustment of amplitude and frequency, etc., to improve processing capacity and improve screening Efficiency and the effect of improving the excitation force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with accompanying drawing.

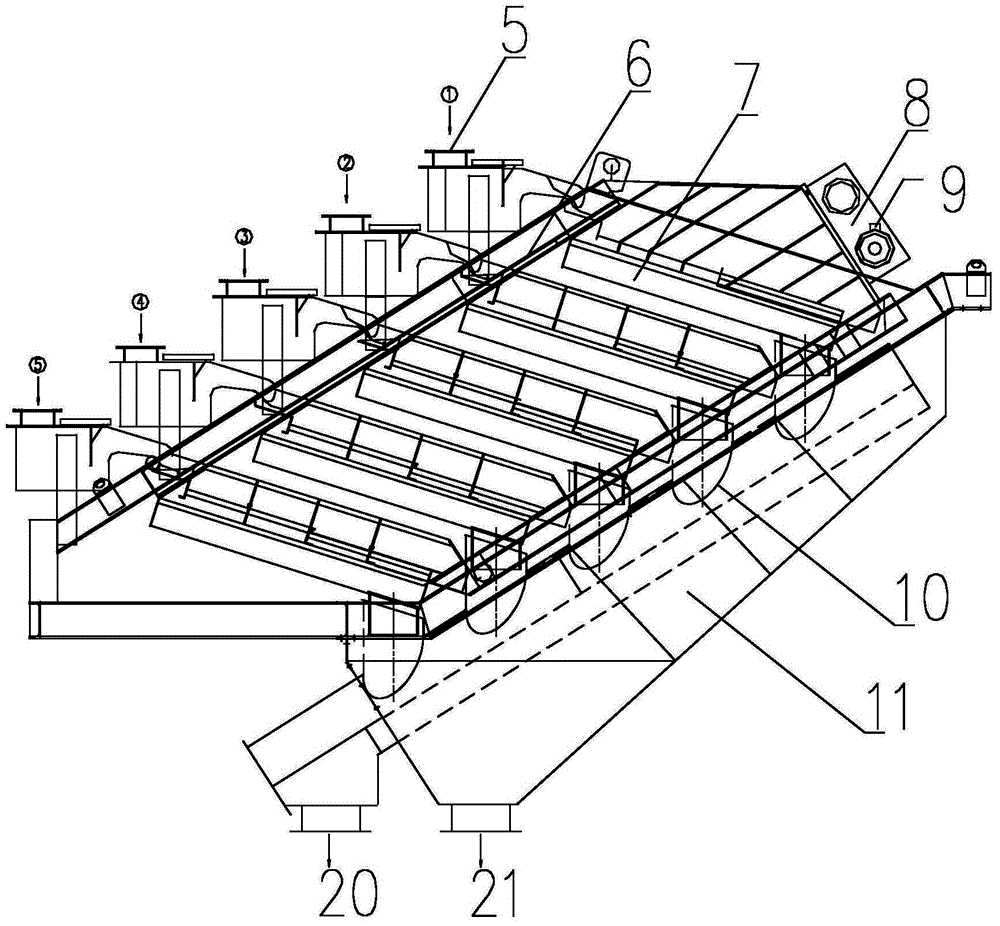

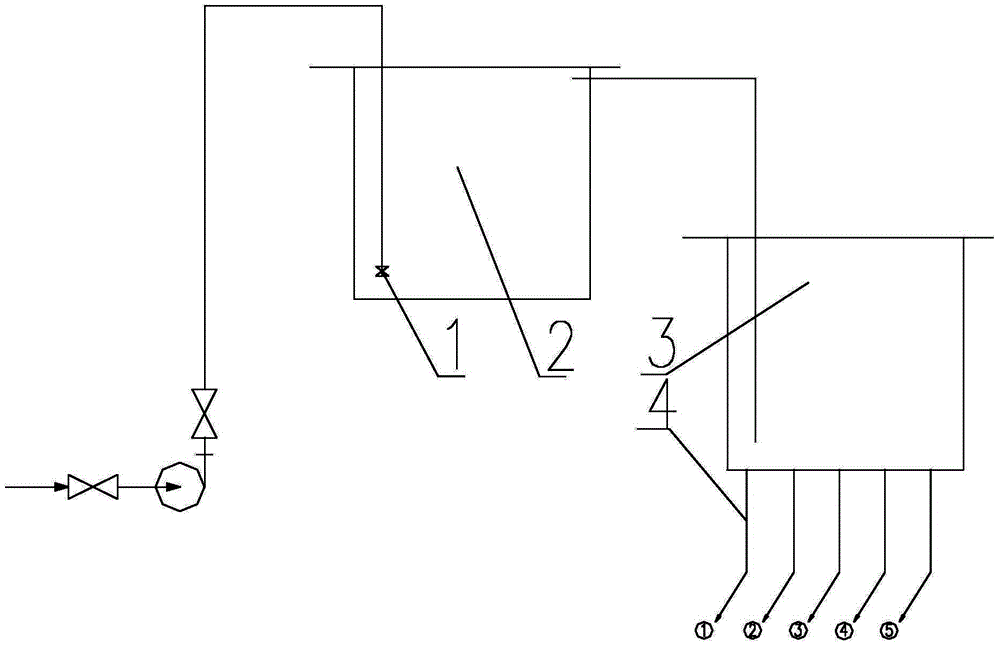

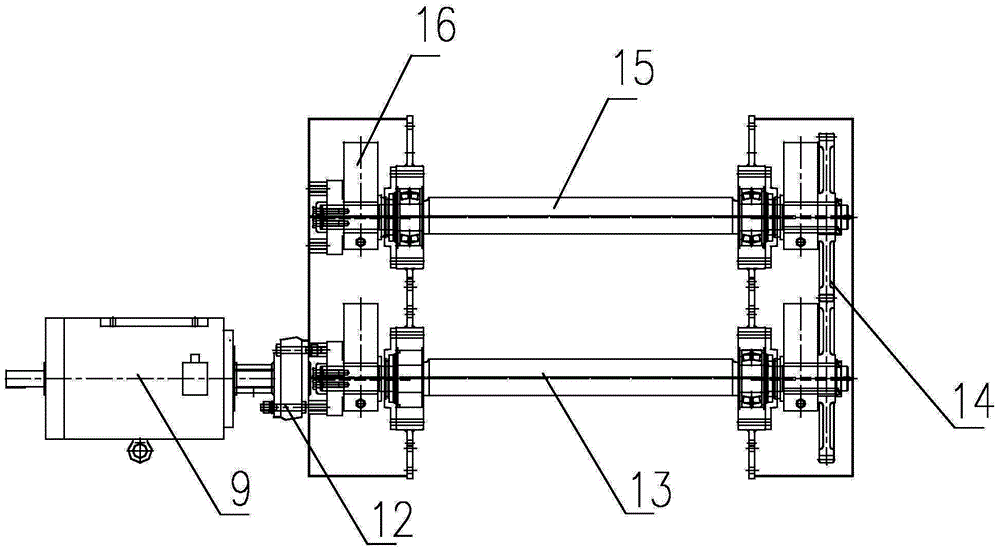

[0032] Laminated high-frequency vibrating fine screen consists of slurry distribution system, screening system and discharge system, see figure 2 , the structure of the pulp distribution system is: the feed end of the primary pulp tank 2 is connected with a porous energy dissipation valve 1, the porous energy dissipation valve 1 dissipates the energy of the pulp from the pump pool, and the overflow of the primary pulp tank 2 The mouth is connected with a secondary slurry storage tank 3, and the lower part of the secondary slurry storage tank 3 is evenly opened in a ring shape. The number of openings is equal to the number of layers of the high-frequency screen assembly 7 of the screening system. Each opening There is a hopper 5 attached; see figure 1 , image 3 , Figure 4 and Figure 5 , the screening system is composed of an excitation unit, a classification unit and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com