Si/c composite, method for manufacturing same, and cathode active material including same for lithium secondary battery

A composite and negative electrode technology, which is applied in the field of Si/C composite and its preparation, can solve the problems such as the decrease of battery cycle characteristics, and achieve the effect of improving electrical conductivity and life-span characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

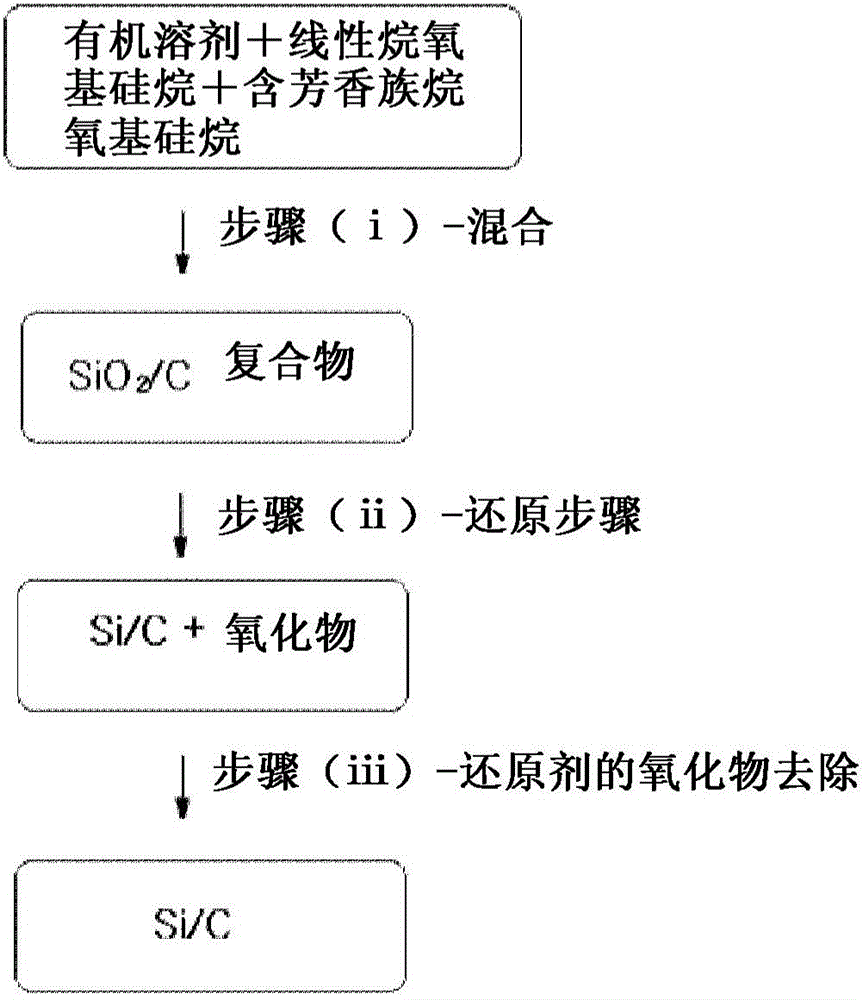

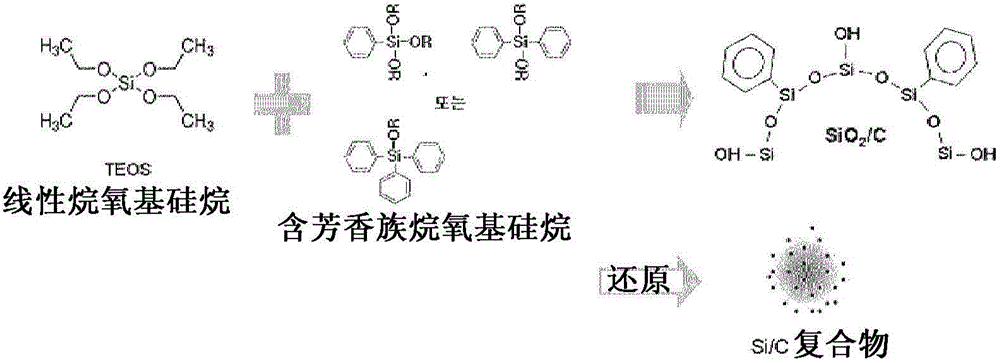

[0048] refer to figure 1 , The preparation method of the Si / C composite of an embodiment of the present invention may include: i) mixing an aromatic alkoxysilane compound represented by the following chemical formula 1 with an organic solvent to form SiO 2 / C complex step, ii) the SiO obtained from step (i) 2 After the / C complex is mixed with an alkali metal or an alkaline earth metal, heat-treating it in an inert atmosphere, thereby reducing the above-mentioned silica, and, iii) performing a heat-treated product obtained in the above-mentioned step (ii) Acid treatment whereby the step of removing oxides;

[0049] Chemical formula 1:

[0050] SiR 1 n R 2 4-n ,

[0051] In the above formula,

[0052] R 1 is phenyl,

[0053] R 2 for C 1 to C 4 alkoxy,

[0054] n is 1 to 3.

[0055] The above step i) is to form SiO 2 The step of / C complex can be obtained by adding the aromatic alkoxysilane compound represented by the above chemical formula 1 to an organic solvent,...

preparation example 1

[0102] Step (i): Preparation of SiO 2 / C complex

[0103] In a 3000ml flask, phenyltriethoxysilane (PTES) (0.82g): tetraethylorthosilicate (TEOS) (41.81g) was mixed at a molar ratio of 1:59 and mixed together with 1400g of ethanol . After the mixture was stirred for 5 minutes at normal temperature in an atmospheric atmosphere, a mixture of 34% ammonia water and deionized water (DIW) was slowly added dropwise, and after stirring for 3 hours, it was allowed to cool at normal temperature. React until gelation occurs. The gel was dried to prepare C / SiO 2 SiO with a ratio of 0.1 2 / C complex.

preparation example 2

[0105] In addition to using PTES:TEOS at a molar ratio of 1:11 in the above-mentioned Preparation Example 1, proceed in the same manner as Preparation Example 1, thus obtaining C / SiO 2 SiO with a ratio of 0.5 2 / C complex.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com