Abrasion-resistant alloy mortar pump impeller and manufacturing method thereof

A wear-resistant alloy and mortar pump technology, which is applied in the direction of pumps, pump components, non-variable pumps, etc., can solve the problems of thermal stress cracks, labor-intensive, high scrap rate, etc., and avoid thermal stress cracks and shrinkage cavities , Reduce production costs and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

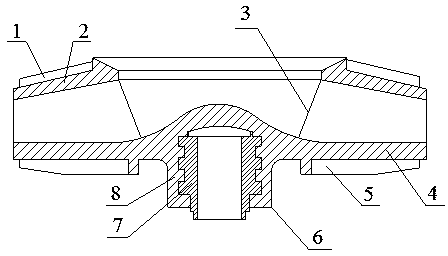

[0021] refer to figure 1 , the impeller of the present embodiment comprises front end cover 2 and rear end cover 4, and front end cover 2 and rear end cover 4 adopt wear-resistant alloy to make, and the surface of front end cover 2 is provided with front auxiliary blade 1, and the surface of rear end cover 4 is provided with There are rear auxiliary blades 5, the front end cover 2 and the rear end cover 4 are connected by blades 3, the middle part of the rear end cover 4 is provided with a shaft hub 6, and the shaft hub 6 includes a pre-embedded part 7 and a pre-embedded matching part 8. Part 7 is made of cast steel, and embedded fitting 8 is made of wear-resistant alloy. Both embedded part 7 and embedded fitting 8 are hollow cylindrical structures. The outer wall of embedded part 7 is provided with two a groove; the inner wall of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com