Oscillating type dampers used for vibration prevention of tower

A damper and swing-type technology is applied in the development and design field of swing dampers for tower anti-vibration, which can solve the problems of few studies on wind-proof and vibration-proof shock absorbers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

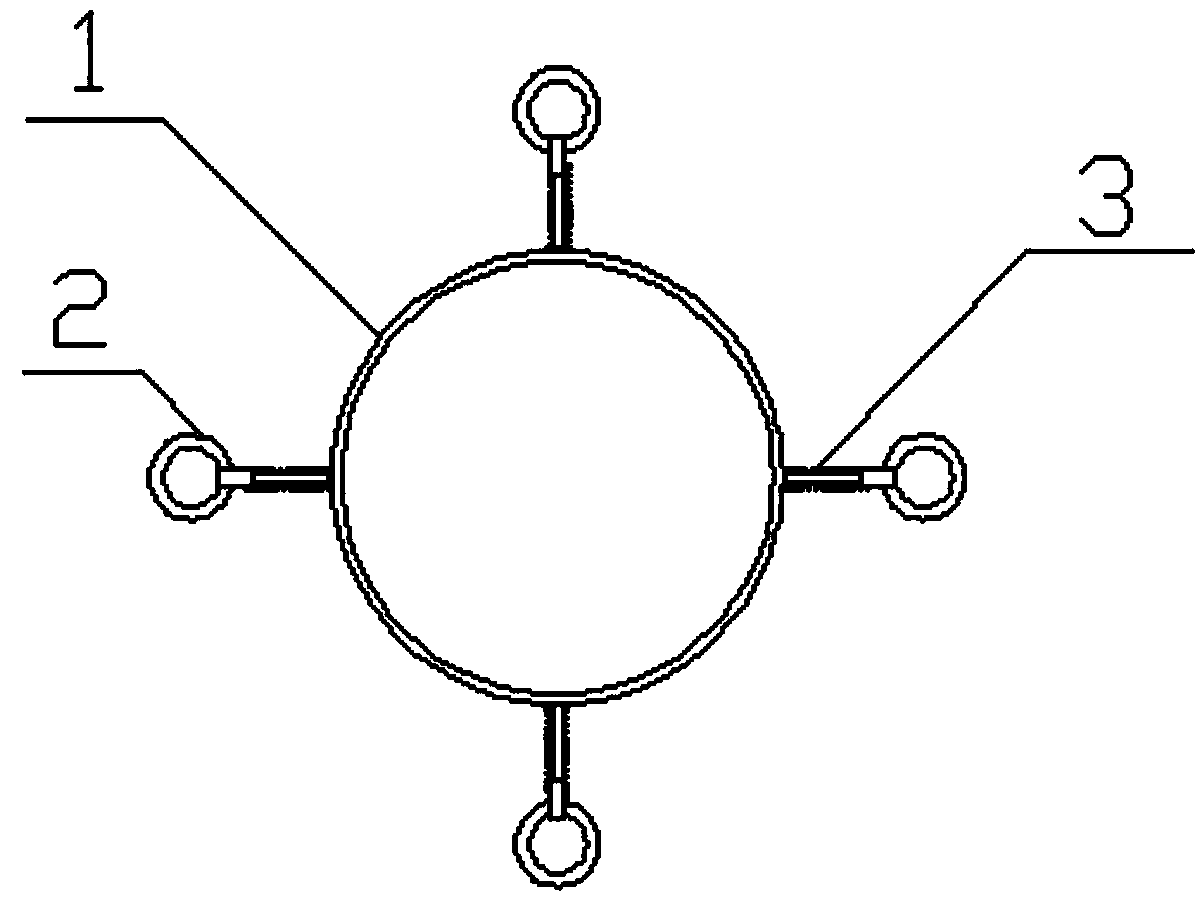

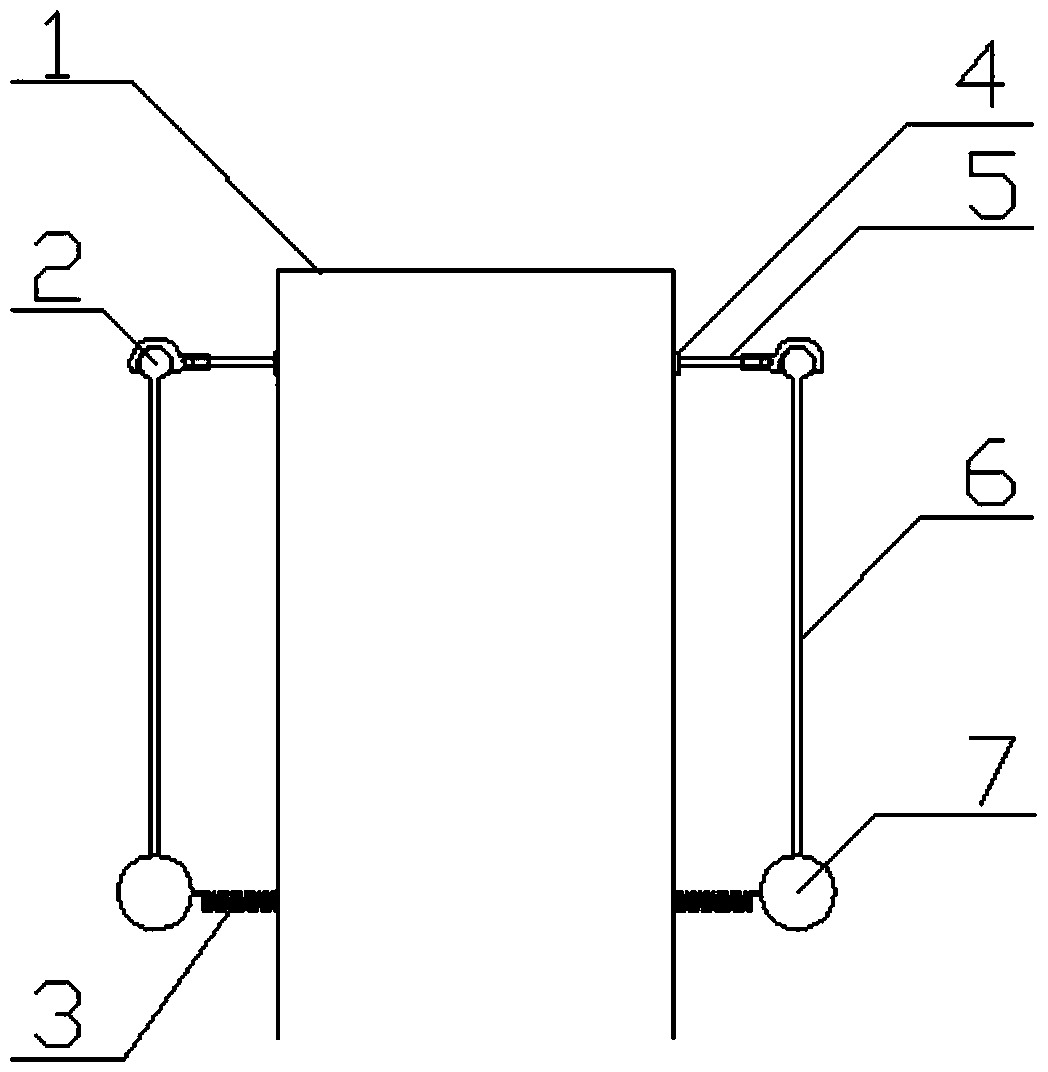

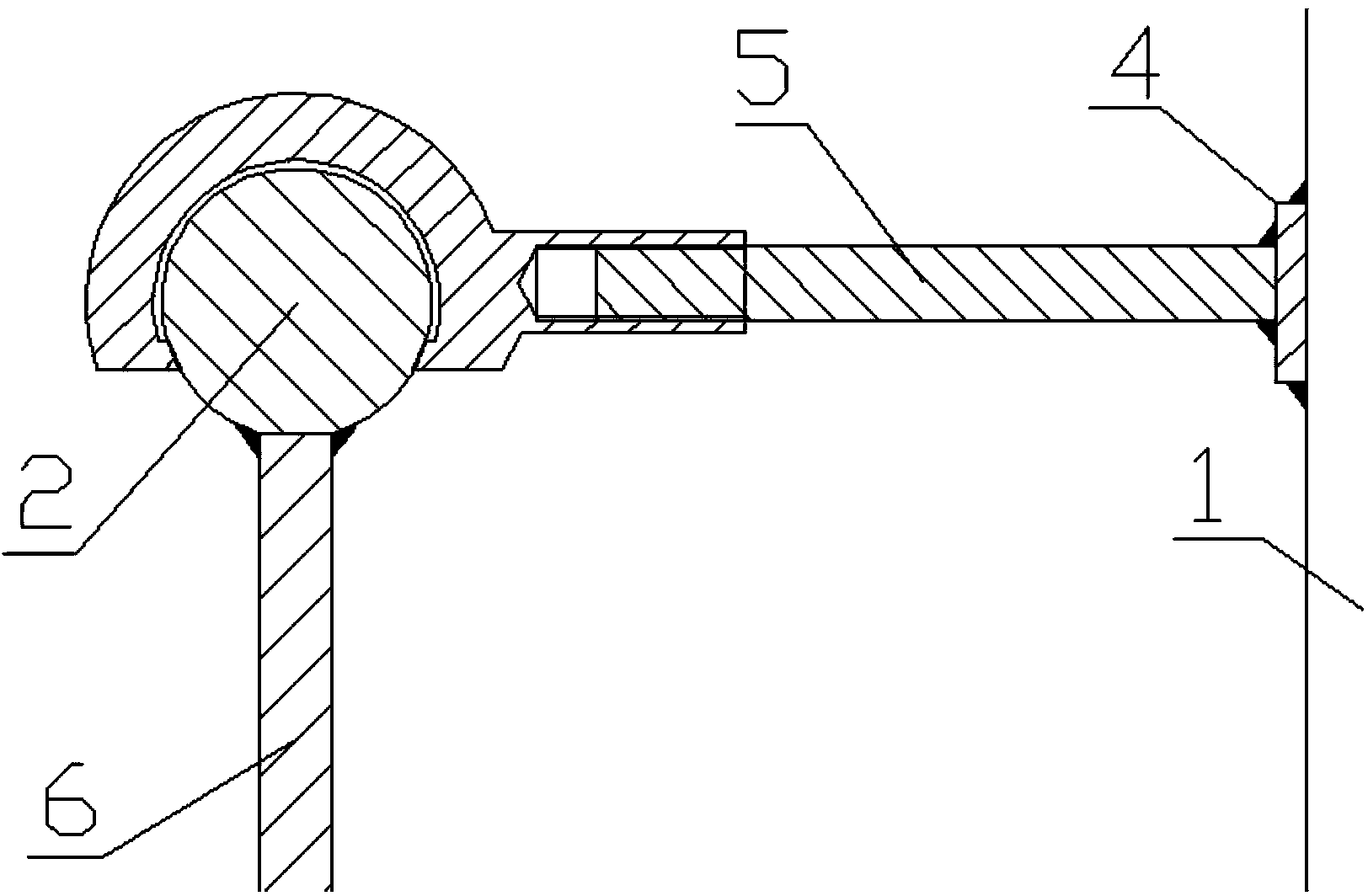

[0055] will figure 2 The damper shown is installed on the top of the tower. One end of the connecting rod 5 is welded to the tower body 1, and the other end is threaded to the ball hinge 2; the pendulum rod 6 is perpendicular to the connecting rod 5, one end of the pendulum rod 6 is welded to the ball hinge 2, and the other end is welded to the mass 7; the spring 3 is connected to the connecting rod. The rod 5 is parallel, one end is welded to the mass 7 and the other end is welded to the tower body 1; there are four dampers in a symmetrical arrangement. Set the connecting rod length to be equal to the tower radius, and set the mass ratio μ to 2%. Under the above conditions, the length ratios of the pendulum rods are set to be 5%, 6.6%, 7.3%, 8%, and 9% respectively. By setting the spring stiffness system k, the vibration frequency of the mass block is consistent with the first-order natural frequency f of the tower. It is proved by experiments that the amplitude y of the to...

example 2

[0057] will figure 2 The damper shown is installed on the top of the tower. One end of the connecting rod 5 is welded to the tower body 1, and the other end is threaded to the ball hinge 2; the pendulum rod 6 is perpendicular to the connecting rod 5, one end of the pendulum rod 6 is welded to the ball hinge 2, and the other end is welded to the mass 7; the spring 3 is connected to the connecting rod. The rod 5 is parallel, one end is welded to the mass 7 and the other end is welded to the tower body 1; there are four dampers in a symmetrical arrangement. Set the connecting rod length equal to the tower radius, and set the pendulum rod length ratio to 9%. Under the above conditions, the mass ratio μ is set to 0.65%, 1.3%, 2%, 3.3%, and 4%, respectively. By setting the spring stiffness system k, the vibration frequency of the mass block is consistent with the first-order natural frequency f of the tower. It is proved by experiments that the amplitude y of the tower top T1 Decr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com