Antifouling method for dredged mud in construction of water dredging engineering

A technology for engineering construction and anti-fouling, applied in river remediation and other directions, can solve problems such as uneconomical, intensified diffusion, manual laying of soil bags, etc., and achieve the effects of preventing secondary pollution, reducing impact force and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A water dredging construction mud throwing anti-fouling method, comprising the following steps:

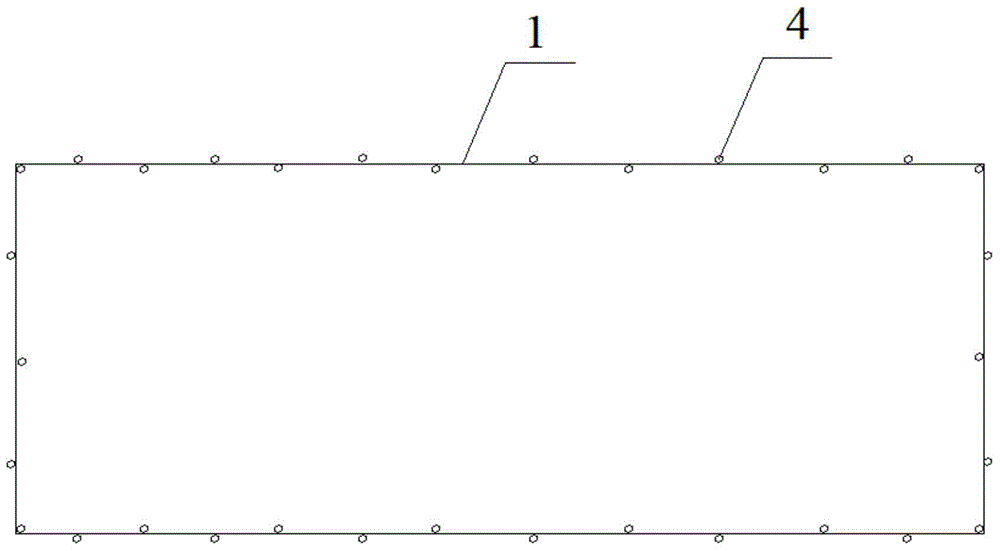

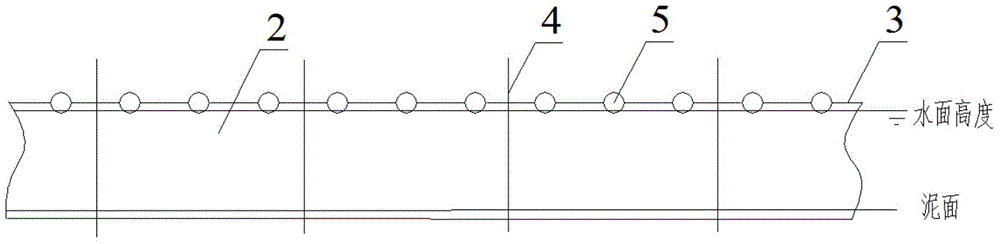

[0033] (1), segmental processing color strip cloth unit, including: the length of each section of color strip cloth is 50m, the width is 6m, the positioning anchor rods are set at intervals of 3m on the color strip cloth, and the adjacent two positioning anchor rods are respectively arranged on the Both sides of the color strip cloth; the bottom end of the color strip cloth is firmly connected with the positioning anchor rod, and the top of the color strip cloth is loosely connected with the positioning anchor rod; 3 floating balls are tied every 1m at the top of the color strip cloth at a distance of 10cm, and the floating The ball is wrapped in a striped cloth;

[0034] (2) At a distance of 200-300m from the outlet of the mud pipe, insert the positioning anchor rod into the mud for 2-3m, so that the bottom of the color strip cloth is close to the mud surface, so that mult...

Embodiment 2

[0038] A water dredging construction mud throwing anti-fouling method, comprising the following steps:

[0039](1), segmental processing color strip cloth unit, including: the length of each section of color strip cloth is 50m, the width is 6m, the positioning anchor rods are set at intervals of 10m on the color strip cloth, and the adjacent two positioning anchor rods are respectively arranged on the Both sides of the color strip cloth; the bottom end of the color strip cloth is firmly connected with the positioning anchor rod, and the top of the color strip cloth is loosely connected with the positioning anchor rod; the foam board is wrapped every 1m at the top of the color strip cloth; every 1m at the bottom end of the color strip cloth parcel pendant;

[0040] (2) At a distance of 200-300m from the outlet of the mud pipe, insert the positioning anchor rod into the mud for 2-3m, so that the bottom of the color strip cloth is close to the mud surface, so that multiple color ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com