Modified polyurethane grouting material and preparation method and application thereof

A grouting material, polyurethane technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of low strength of the consolidated body, complicated operation process, pollution of the environment, etc., and achieve high strength and penetration of the foamed consolidated body. Good performance and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0015] The invention provides a kind of preparation method of modified polyurethane grouting material, wherein, the method comprises the following steps:

[0016] Step 1: contact and mix diluent, isocyanate compound, water and portland cement to obtain component A;

[0017] Contact and mix the polymeric alcohol, foam stabilizer and catalyst to obtain component B;

[0018] Step 2: Mix component A and component B evenly.

[0019] Wherein, in step 1, the process of contacting and mixing to obtain component A can be carried out according to the following steps: firstly, the diluent and the isocyanate compound are contacted and mixed, and then the mixture 1 is contacted with water to obtain the mixture 2, and then the mixture 2 is mixed with silicon Salt cement is contacted to obtain Component A.

[0020] In Step 1, the process of contacting and mixing to obtain component B can be carried out according to the following steps: first contact and mix the polymer alcohol with the foa...

Embodiment 1-9

[0051]Examples 1-9 are used to illustrate the preparation method of the modified polyurethane grouting material provided by the present invention.

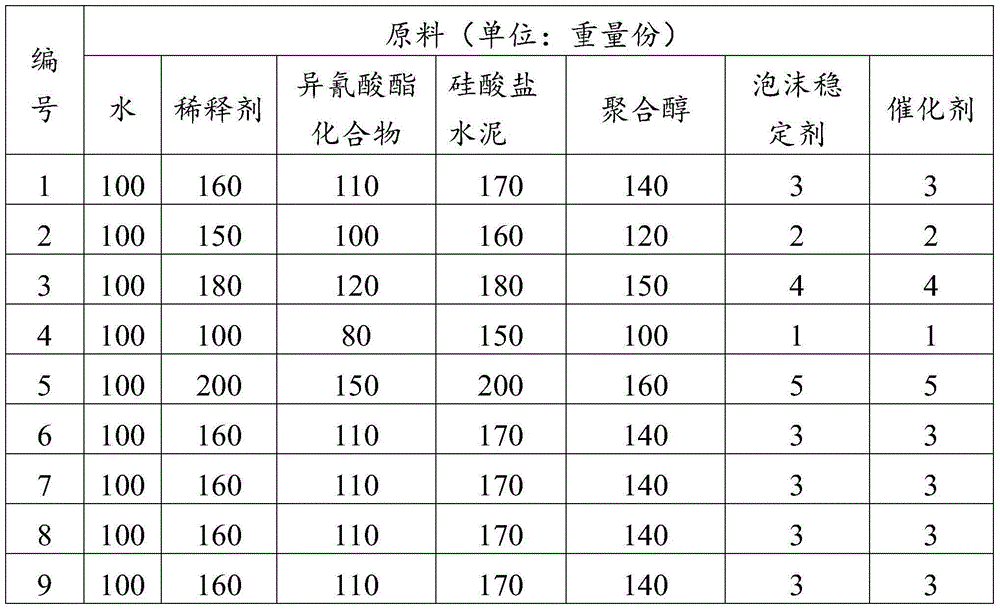

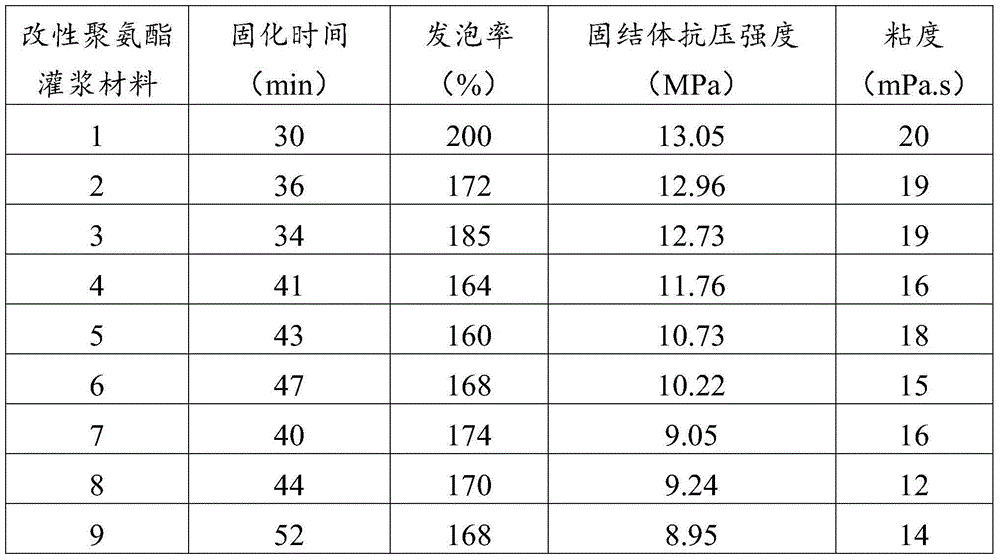

[0052] According to the component content listed in Table 2, the modified polyurethane grouting material was prepared.

[0053] In the mixing kettle, firstly add diluent, then add isocyanate compound and stir evenly, then add water and mix evenly, finally add portland cement and mix evenly under normal pressure to prepare component A.

[0054] In the mixing kettle, firstly add the polymer alcohol, then add the foam stabilizer and stir evenly, and finally add the catalyst, stir and mix evenly to prepare component B.

[0055] Mix component A and component B uniformly to obtain modified polyurethane grouting material.

[0056] Table 2

[0057]

[0058] In embodiment 1-9, the specific selection of each component is as follows:

[0059] The selection of each component among the embodiment 1-5 is as follows: diluent (butyl acetate...

Embodiment 6

[0061] The modified polyurethane grouting material was prepared according to the method of Example 1, except that the diluent was mixed with butyl acetate and methylene chloride at a weight ratio of 17:23.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com