Method of Controlling Waves in Straightening Wide and Thick Plates

A control method and technology for wide and thick plates, which is applied in the field of straightening control of wide and thick plates, can solve the problems of different cooling speeds, easy generation of waves in plates, uneven rolling deformation, etc., and achieve the effect of eliminating the defects of waves and eliminating waves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

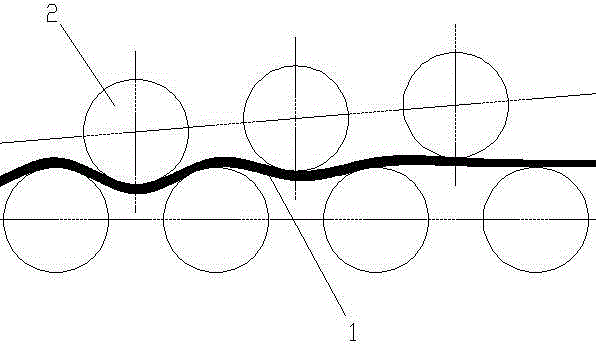

Image

Examples

Embodiment 1

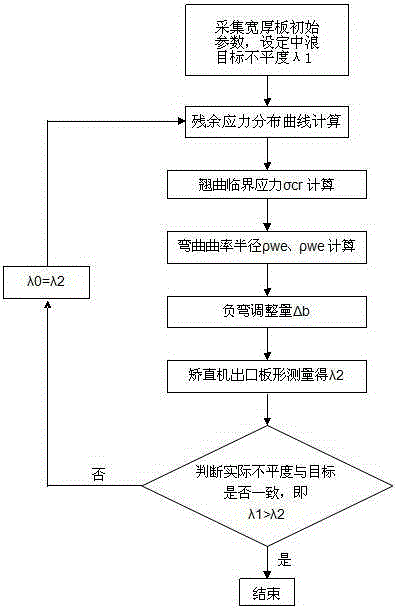

[0036] Such as figure 2 As shown, a method for controlling waves in straightening wide and thick plates is characterized in that it comprises the following steps:

[0037] Step 1. The process control computer system is based on the steel type and specification of the wide and thick plate, the initial bending radius of curvature ρ0 and the initial mid-wave roughness λ 0 , set the target roughness λ of the medium wave 1 ;

[0038] Step 2. According to the parameters collected in step 1, calculate the residual stress distribution curve σ(x) of the wide and thick plate, take the width direction of the wide and thick plate as the x-axis, and take the center of the plate width as the origin

[0039] (2)

[0040] In the formula, ars, a1, a2 are empirical parameters, obtained from experiments, ars=(0.6~1.2)×10 -5 , a1=0.3~0.8, a2=-5.0~-1.5;

[0041] H is the thickness of wide and thick plate;

[0042] B is the width of wide and thick plate;

[0043] σcr is the warping critic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com