Straightening structure for groove-shaped rail

A grooved rail and straightening technology, which is applied in the field of profile rolling, can solve problems such as waist bending deformation, asymmetry, and cracking at the bottom of the rail groove, so as to optimize the stress state, prevent waist deformation, and ensure balance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

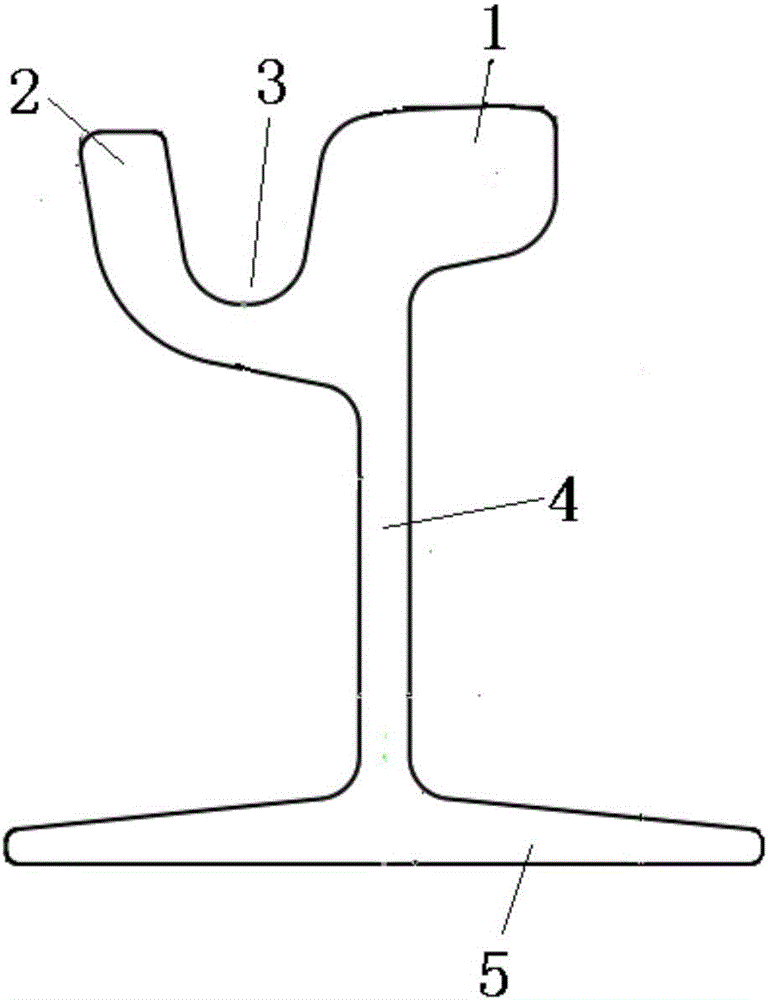

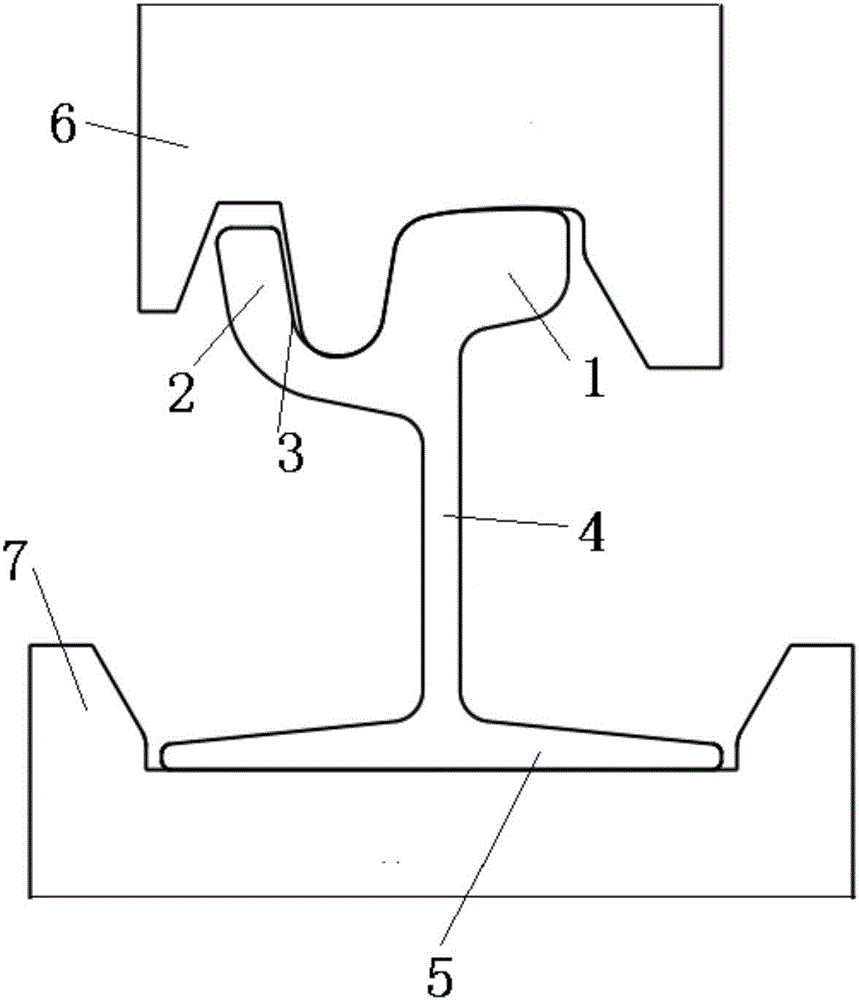

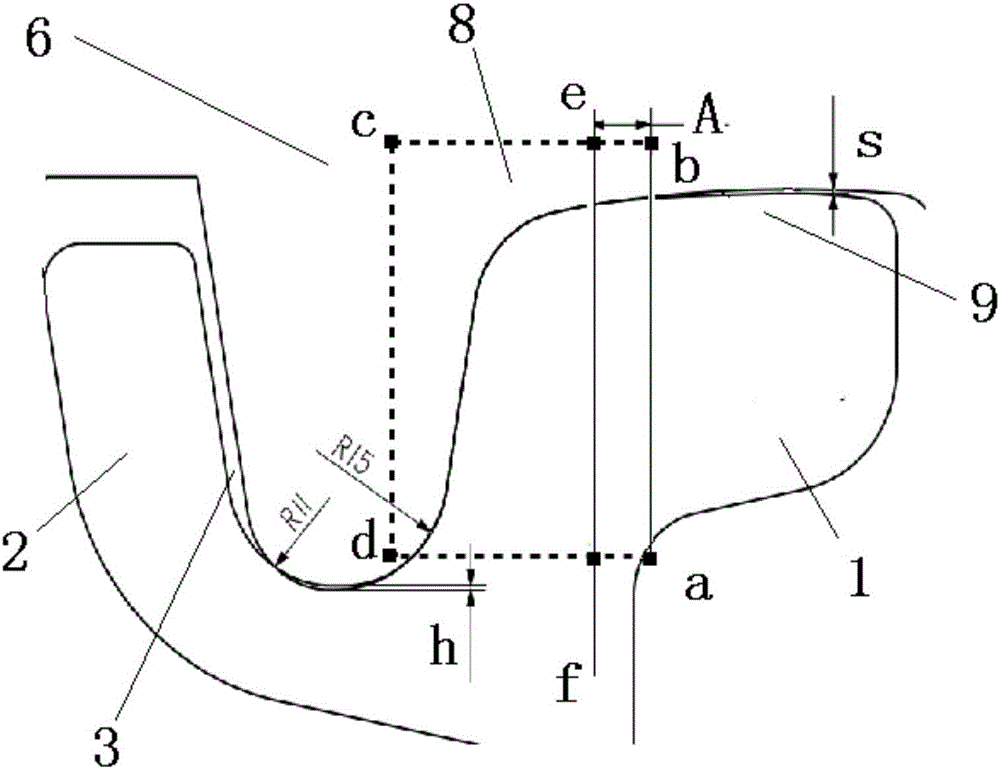

[0018] Such as figure 1 , figure 2 , image 3 The straightening structure of the grooved rail shown includes the grooved rail to be straightened. The top of the grooved rail is composed of a rail head 1, a rail groove 3 and a rail lip 2, the middle part is composed of a rail waist 4, and the bottom is composed of a rail bottom 5 It also includes a straightening roller composed of a straightening upper roller 6 and a straightening lower roller 7, the rail bottom 5 of the grooved rail is arranged on the straightening lower roller 7, and the straightening upper roller 6 is arranged on the rail head 1 and the rail groove 3 Above, the straightening upper roller 6 is embedded in the rail groove 3 and is attached to the inner wall of the rail groove 3 through the left arc (R11) and the right arc (R15) of the straightening upper roller 6 respectively, and the straightening ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com