Lattice screen and processing process thereof

A processing technology and grid technology, applied in the field of screens and their processing technology, can solve the problems of unsightly appearance, inconvenient processing, poor mechanical properties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

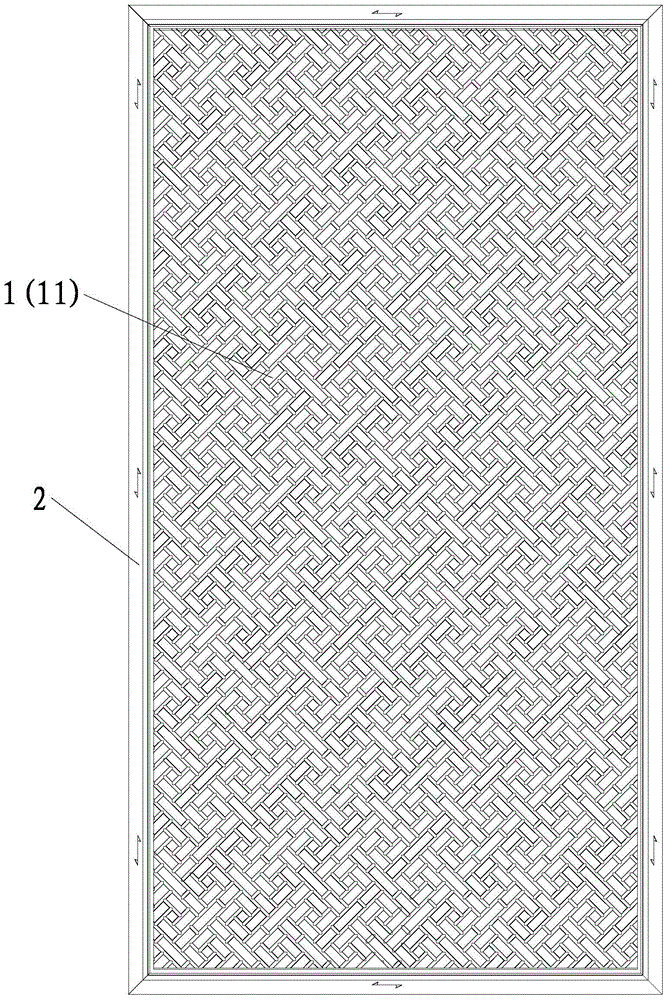

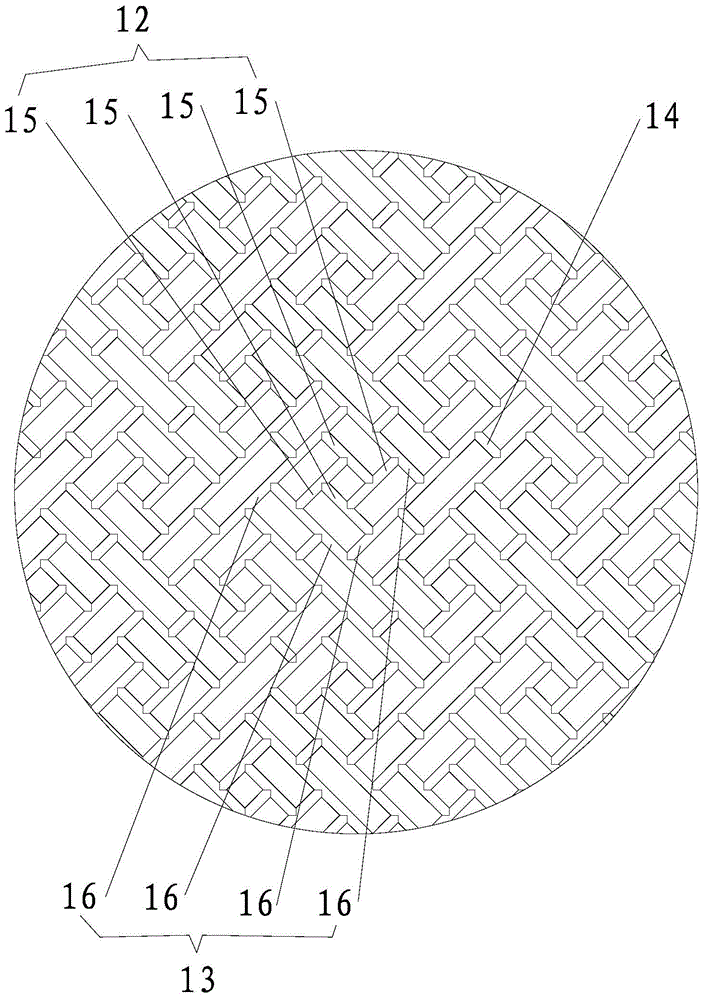

[0041] Such as figure 1 and figure 2 As shown, the lattice screen provided in this embodiment includes a screen board 1 and a square frame 2 surrounding the screen board 1 . The screen panel 1 includes a grille panel 11, and the grille panel 11 includes an inner skeleton structure 12 and an outer skeleton structure 13 with the same structure, and a connecting keel 14 connected between the outer skeleton structures 13. Of course, the inner skeleton structure 12 and the outer skeleton structure 13 sizes are different. The inner skeleton structure 12 includes four inner keels 15 vertically connected to each other, and the two inner keels 15 connected to each other form a "T" shape; the outer skeleton structure 13 includes four outer keels 16 connected vertically to each other. Also become " T " font between two outer keels 16 . The inner skeleton structure 12 is integrally embedded in the outer skeleton structure 13, and the four inner keels 15 on the inner skeleton structure...

Embodiment 2

[0053] The difference between the grille screen provided in this embodiment and the first embodiment is that the screen board 1 also includes a glass plate (not shown in the figure), and the glass plate is attached to the grille board 11, so that the windshield effect of the grille screen is better.

[0054] The grille panels 11 contained in the screen panel 1 are the same size as the glass panels, and the number can be selected according to actual needs. In this embodiment, three screen panels 1 with different stacking methods of the grille panels 11 and glass panels are provided. A kind of screen panel 1 comprises a grille plate 11 and a glass plate, and the grille plate 11 and the glass plate are attached to each other; the second screen panel 1 comprises a grille plate 11 and two glass plates, and the two glass plates will The grille plate 11 is sandwiched in the middle; the third screen panel 1 includes two grille plates 11 and a glass plate, and the two grille plates 11 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com