Oil pumping unit motor dynamic load simulated loading system and oil pumping unit motor dynamic load simulated loading method

A dynamic load, electromechanical technology, used in motor generator testing and other directions, to achieve strong versatility and save construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

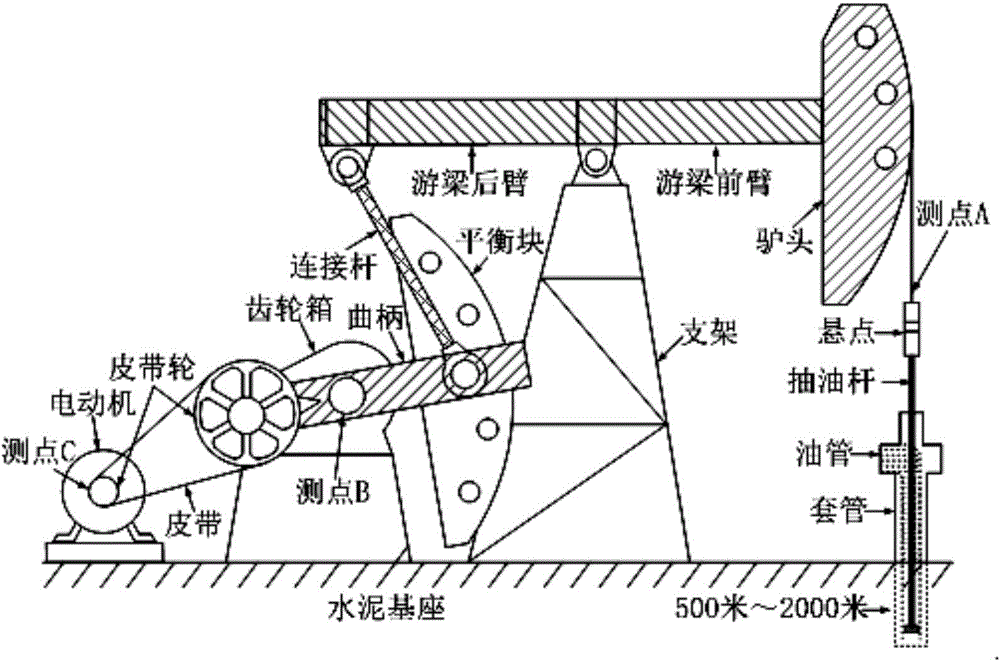

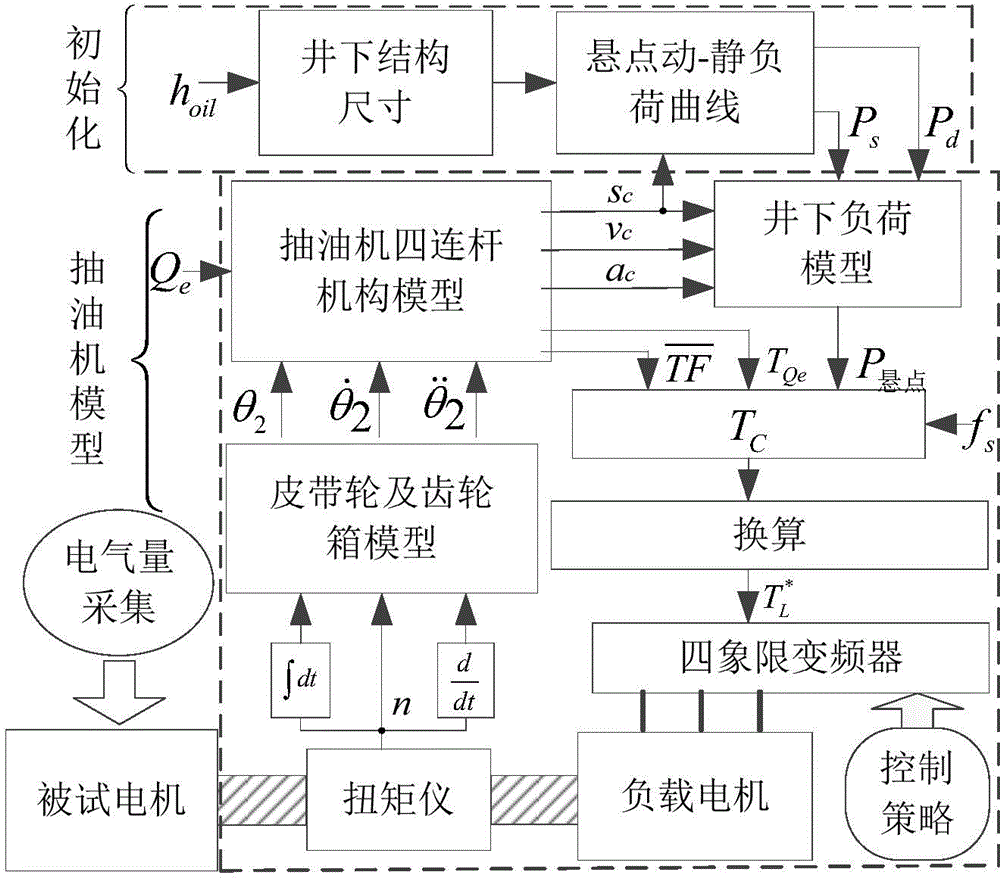

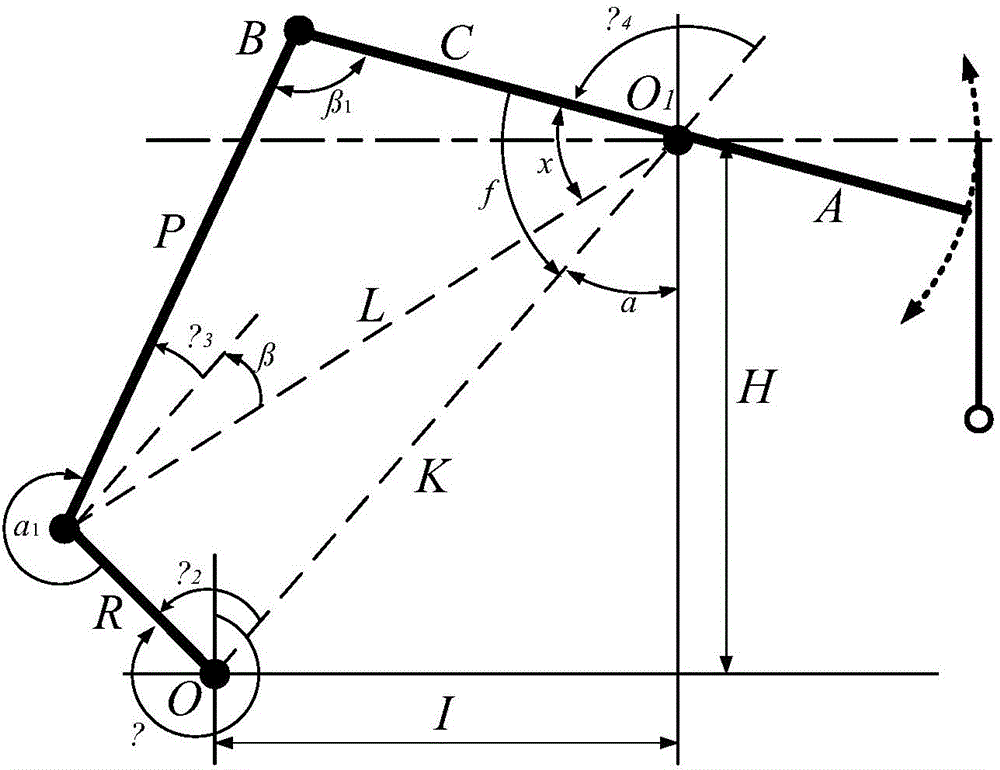

example 1

[0124] Pumping unit model: CYJ10-3-37HB; structural parameters: crank R = 1.15m, connecting rod P = 3.35m, beam rear arm C = 2.4m, beam forearm A = 3.0m, base rod projection I = 2.3m, the height of the supporting point of the beam from the center of the gear box is H=3.28m, the structural unbalance block Bw=0; downhole parameters: pump depth L=940m, dynamic fluid surface hoil=300m, sucker rod diameter D=30mm; belt , Gear box parameters: k = 149.33, η = 0.88; four connecting rods: η 1 = 0.95; the load unit selects Siemens S120 series four-quadrant frequency converter and 1FT6 series permanent magnet servo motor, and the driving accuracy is 1.0%. According to the above pumping well parameters, the parameters of the BPs model of the upper computer are correspondingly modified. The tested motor is a Y2 series 8-pole 37kW ordinary three-phase asynchronous motor. The indoor simulation test data and the outdoor pumping unit measured results are as follows: Figure 5 shown. combine ...

example 2

[0126] When the dynamic liquid level is about 400 meters, the test results using the indoor simulation loading system are compared with the measured input power, motor output torque and speed of the outdoor standard well. Figure 7 As shown, among them, Figure 7 (a) is a comparison chart of the input power of the simulated loading system and the actual measurement; Figure 7 (b) is a comparison diagram of the torque of the simulated loading system and the actual measurement; Figure 7 (c) is a comparison chart of the rotational speed of the simulated loading system and the actual measurement. It can be seen that the input active power, load torque and motor speed changes of the tested motor are basically consistent with the measured results of the standard well.

example 3

[0128] When the dynamic liquid level is about 500 meters, the test results using the indoor simulation loading system are compared with the measured input power, motor output torque and speed of the outdoor standard well. Figure 8 As shown, among them, Figure 8 (a) is a comparison chart of the input power of the simulated loading system and the actual measurement; Figure 8 (b) is a comparison diagram of the torque of the simulated loading system and the actual measurement; Figure 8 (c) is a comparison chart of the rotational speed of the simulated loading system and the actual measurement. It can be seen that the input active power, load torque and motor speed changes of the tested motor are basically consistent with the measured results of the standard well.

[0129] The beneficial effects of the present invention are:

[0130] (1) By using the simulated loading system provided in the present invention, when testing the operating performance of the motor under dynamic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com