A floating bearing structure for small turbocharger

A turbocharger and floating bearing technology, which is applied in the mechanical field, can solve the problems of reducing shafting efficiency, shafting instability, deflection deformation and large runout, etc., and achieves good oil equivalent heat capacity and heat dissipation performance. Reliable stability improvement, small deflection and runout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

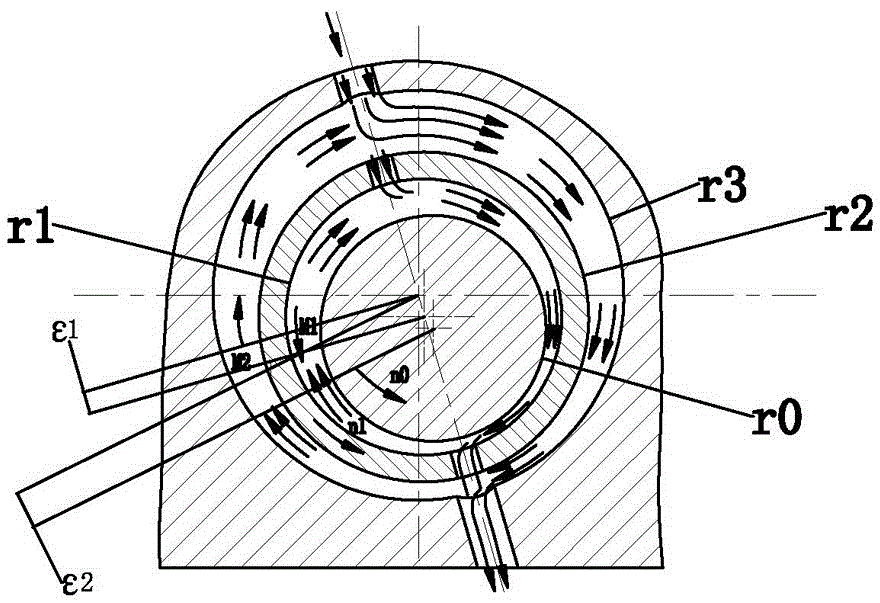

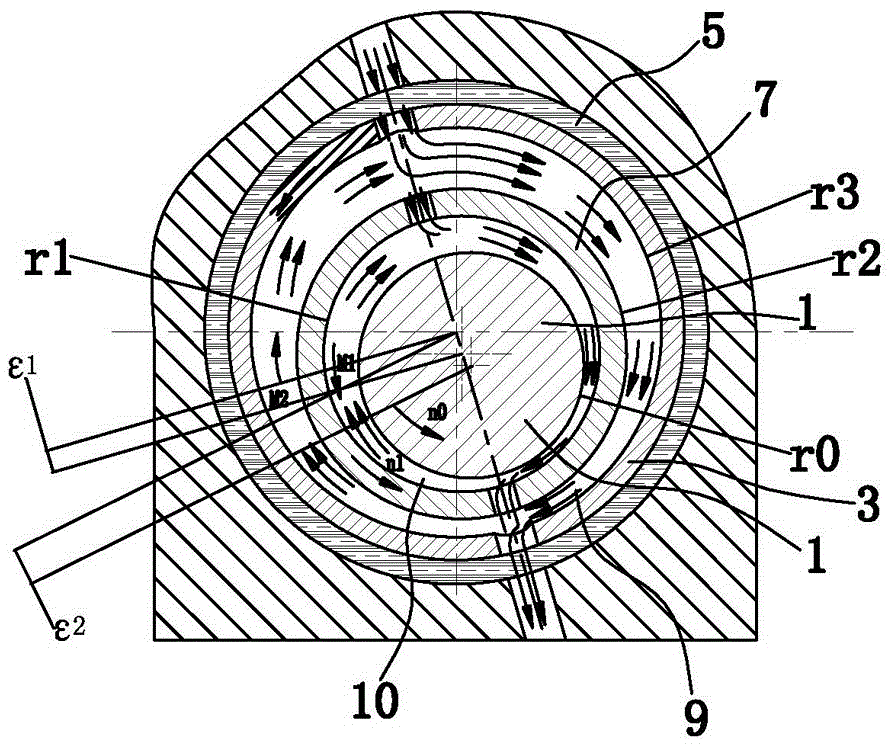

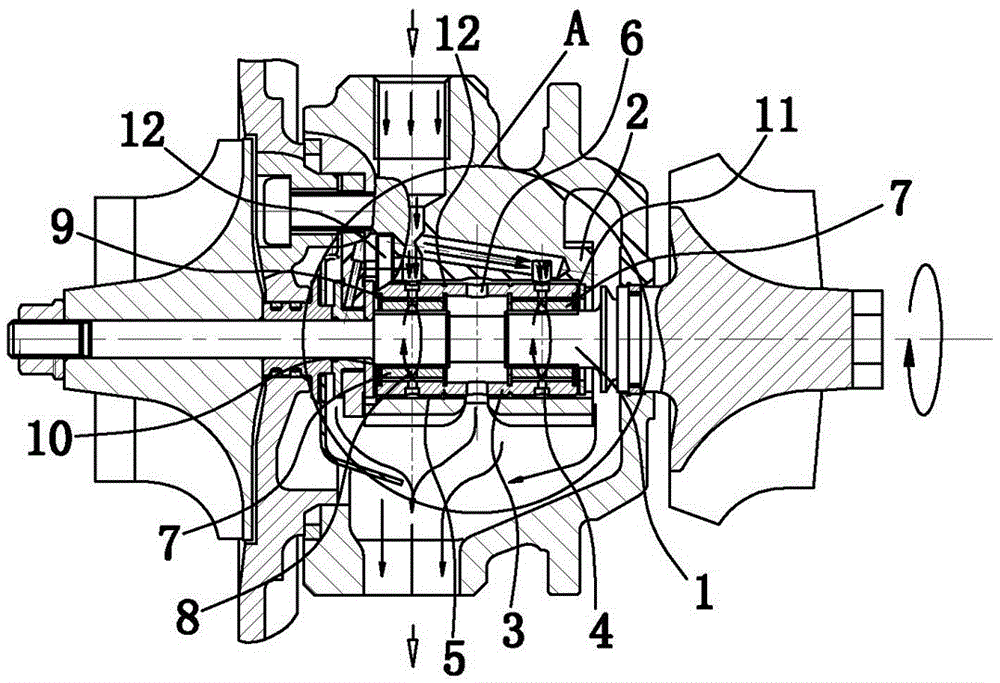

[0039] Such as image 3 As shown, the floating bearing structure used for a small turbocharger includes a single semi-floating bearing sleeve 3 that is sleeved on the turbine shaft 1 and positioned with the bearing body 2. In this embodiment, the bearing body 2 is pierced with a positioning Pin 12, the end portion of locating pin 12 radially penetrates one end of the single semi-floating bearing sleeve 3, so that the positioning of the single semi-floating bearing sleeve 3 and the bearing body 2 is convenient. There are several oil holes-4 on the single semi-floating bearing sleeve 3 and there is a static oil film gap 5 between the single semi-floating bearing sleeve 3 and the bearing body 2, and an oil return hole is open...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com