Automatic wall plastering machine

A wall plastering machine and automatic technology, applied in the direction of construction, building structure, etc., can solve the problems of fixed length of vertical track and low construction efficiency, and achieve the effect of high work efficiency, convenient operation, automation and artificial intelligence.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

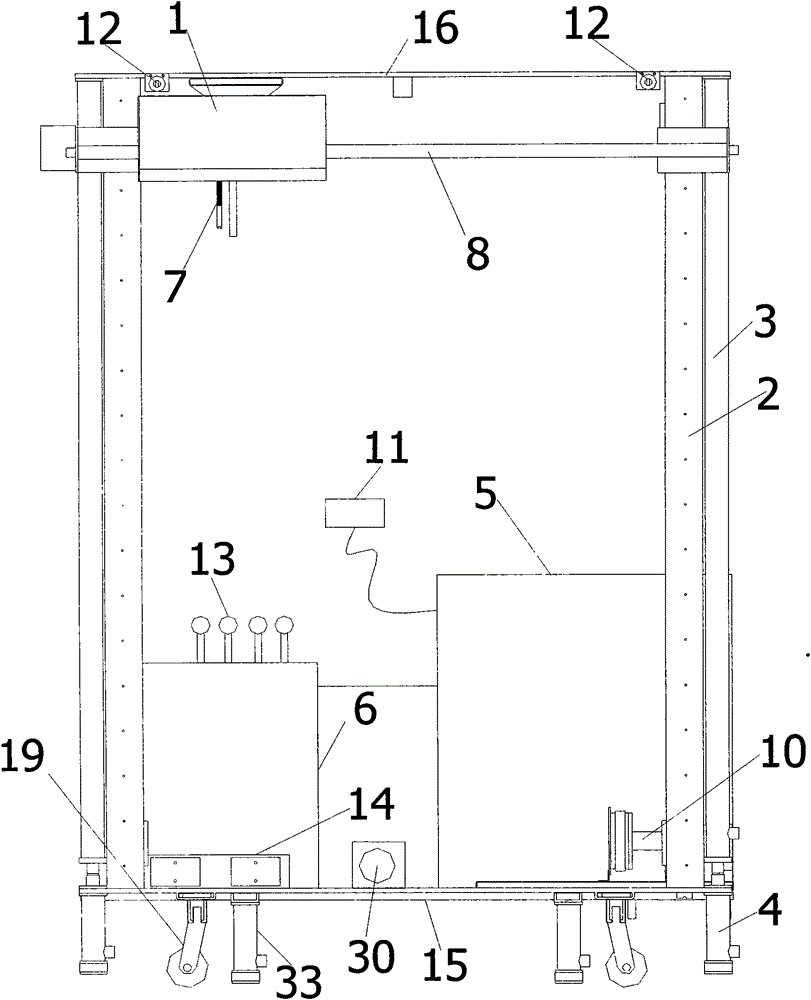

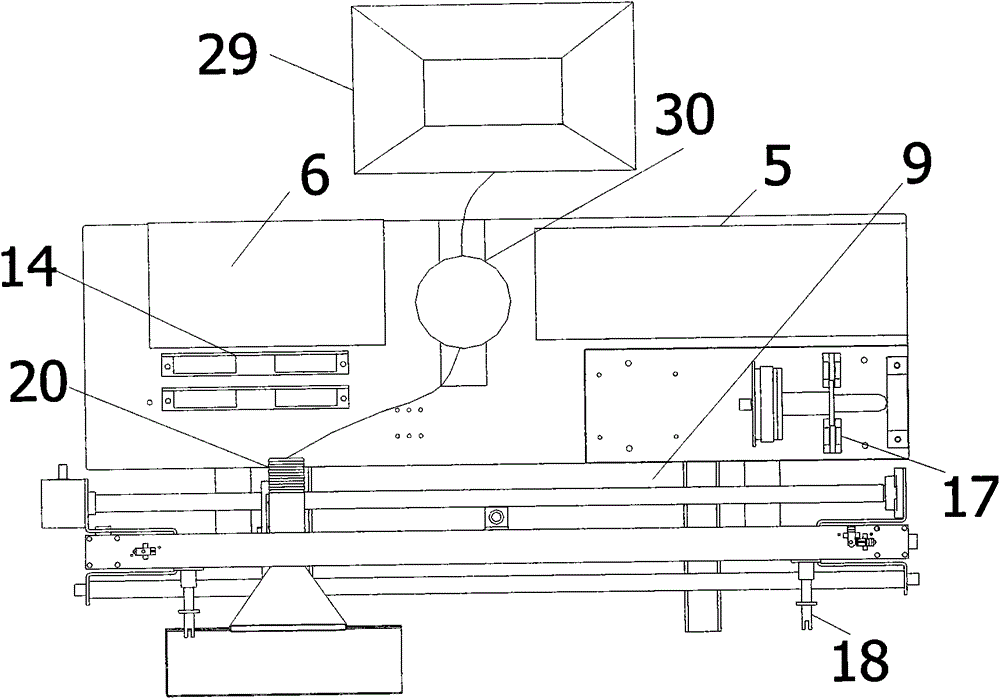

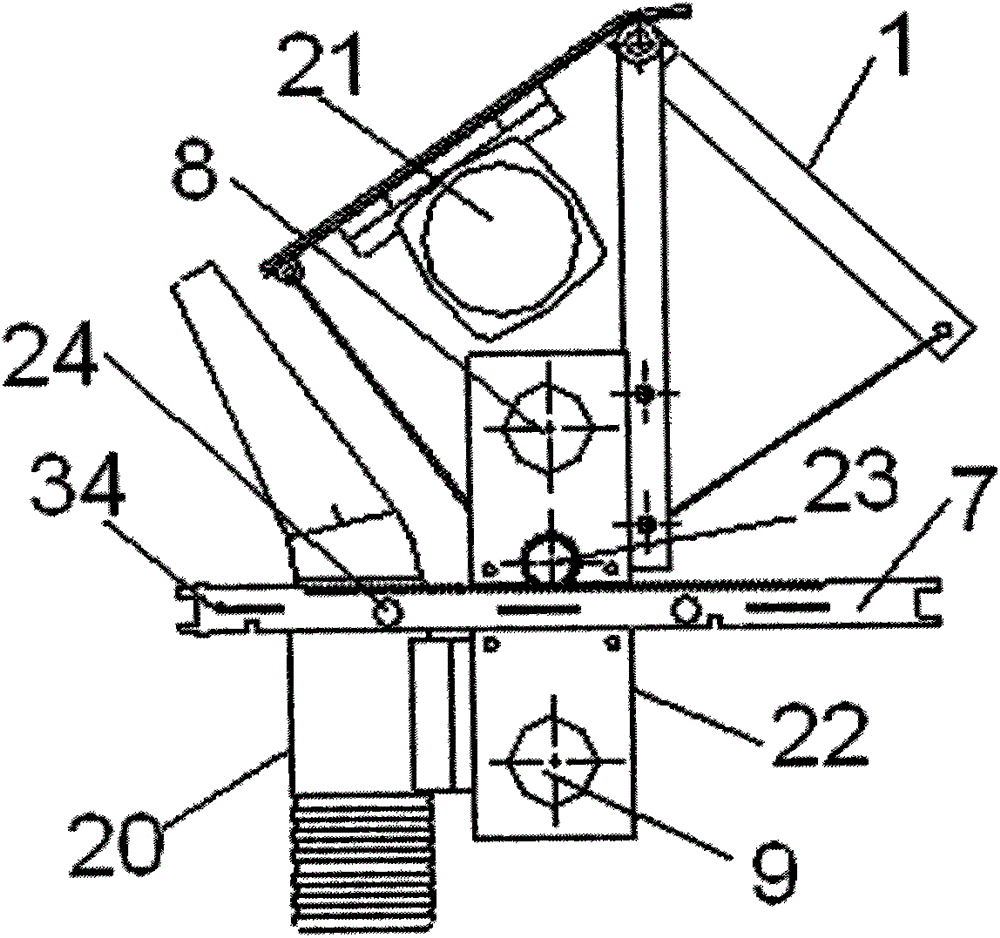

[0019] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 Shown: an automatic wall plastering machine, which is mainly composed of a frame body, an automatic feeding mechanism, an automatic positioning mechanism, a winch mechanism 10, a slideway mechanism, a plastering mechanism and an electric control mechanism. The frame body includes a lower bracket 15 and an upper bracket 16. The automatic feeding mechanism is composed of a hopper 29, a hose pump 30 and a feeding pipe. The hopper 29 is connected to the hose pump 30, and the outlet of the hose pump 30 is connected to the feeding pipe; the automatic positioning mechanism is mainly composed of a hydraulic station 6, The four-cylinder control valve 13, the self-locking device 14 and eight hydraulic cylinders are formed, and each of the eight hydraulic cylinders is a group of two, which are respectively the front foot cylinder 33, the rear foot cylinder 4, the slideway adjustment cylinder 18 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com