A double-sided horizontal push brake type vehicle reducer actuator

A technology of an actuator and a reducer, which is applied in the field of double-sided flat-push brake type vehicle reducer actuators, can solve the problems of untimely and unstable braking and mitigation responses, and achieve stable and reliable braking performance. , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

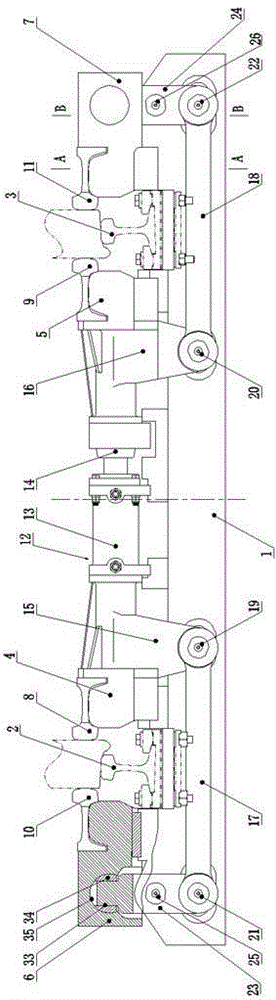

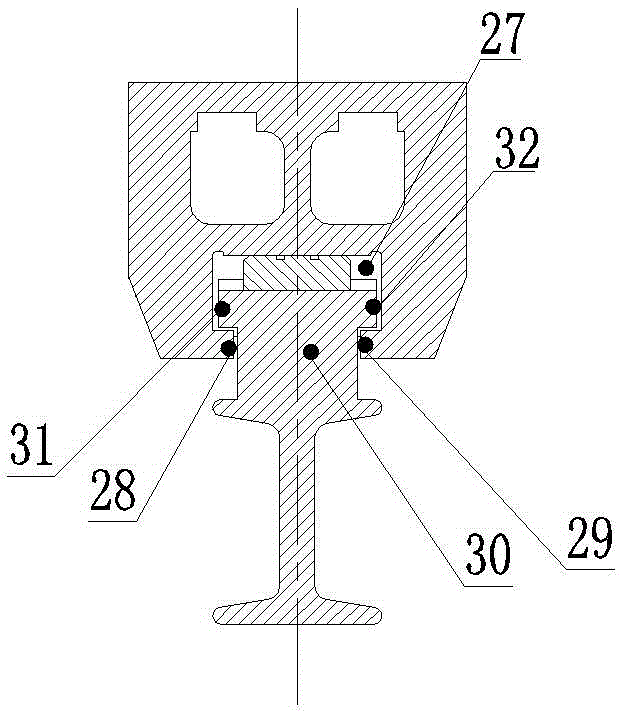

[0025] In order to overcome the problems of untimely braking and mitigation response, instability and potential safety hazards existing in the existing double-sided brake joist structure type vehicle reducer actuator, this embodiment provides a figure 1 In the double-sided flat-push braking type vehicle reducer actuator shown, except for the oil cylinder, the left and right parts are all symmetrical to the center of the basic line, mainly including a plurality of parallel joists 1, and the top surface of the left and right ends of each joist 1 Each installs a basic rail 2,3 parallel to each other, and the inner and outer sides of the two basic rails 2,3 are provided with inner brake rail seats 4,5 and outer brake rail seats 6,7, and the inner brake rails The top surfaces of seats 4, 5 and outer brake rail seats 6, 7 are respectively provided with an inner brake rail 8, 9 and an outer brake rail 10, 11, on the joist 1 between the two basic rails 2, 3 A double-acting oil cylinde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com