Bonding device for realizing binding of two-layer film structure in one-step main bonding

A pressing device and a double-layer film technology, applied in the field of pressing devices, can solve problems such as failure to detect problems in time, high turnover, and affecting the efficiency of the press, so as to avoid batch functional problems, reduce turnover, and improve the efficiency of the press Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

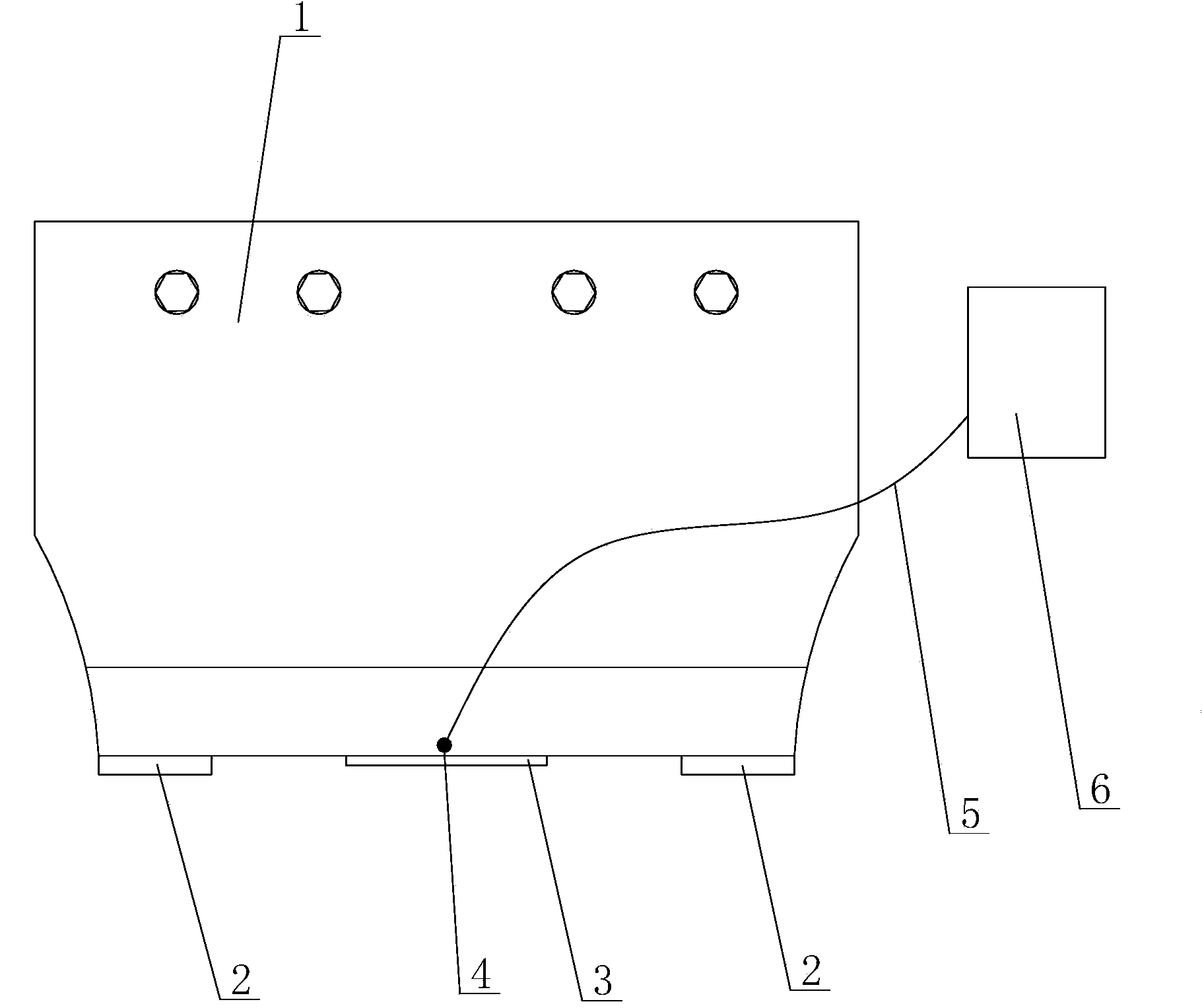

[0022] see figure 1 as shown, figure 1 It is a structural schematic diagram of a lamination device for one-time lamination to realize the binding of a double-layer film structure provided in Embodiment 1 of the present invention.

[0023] In this embodiment, the lamination device for realizing the binding of the double-layer film structure at one time includes an indenter body 1, and two side indenters 2 are correspondingly extended downwards on both sides of the indenter body 1. An intermediate indenter 3 extends downward from the indenter body 1 between the side indenters 2, the heights of the two side indenters 2 are the same, and the height of the intermediate indenter 3 is smaller than the height of the two side indenters 2 . And the height difference between the two side indenters 2 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com