Rubber wheel assembly device

A technology for assembling device and rubber wheel, which is applied to hand-held tools, manufacturing tools, etc., can solve the problems of time-consuming and labor-intensive, difficult to guarantee product quality, and easy to damage rubber wheels, etc., and achieves simple production, safe and convenient application, simple and economical cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

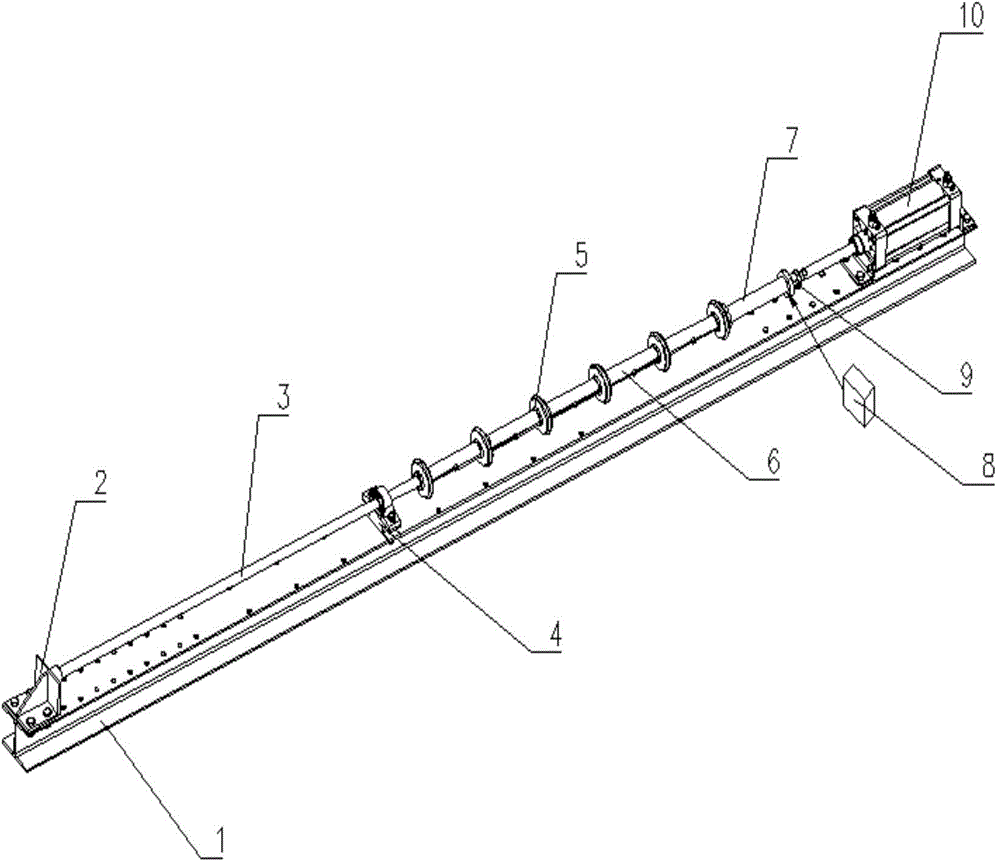

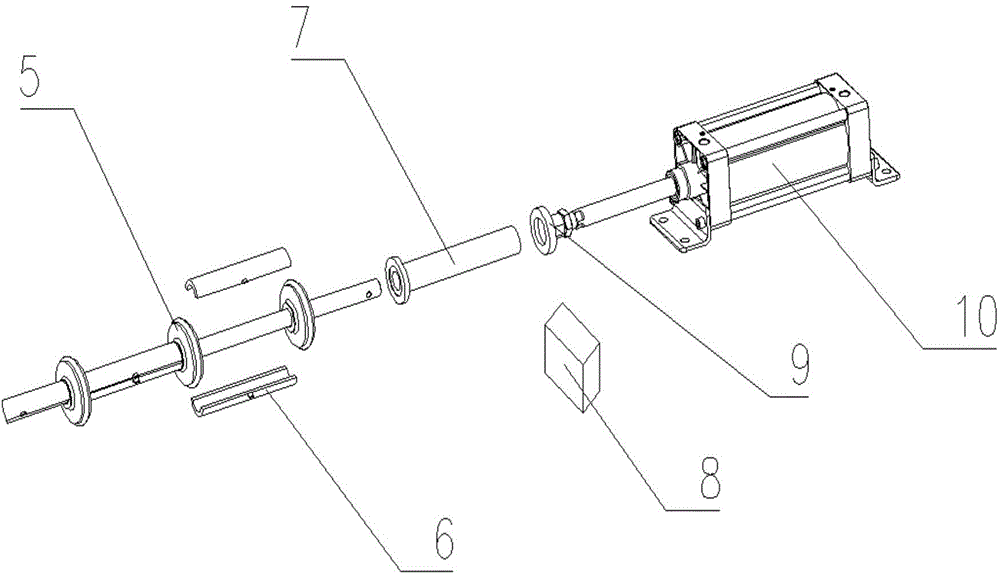

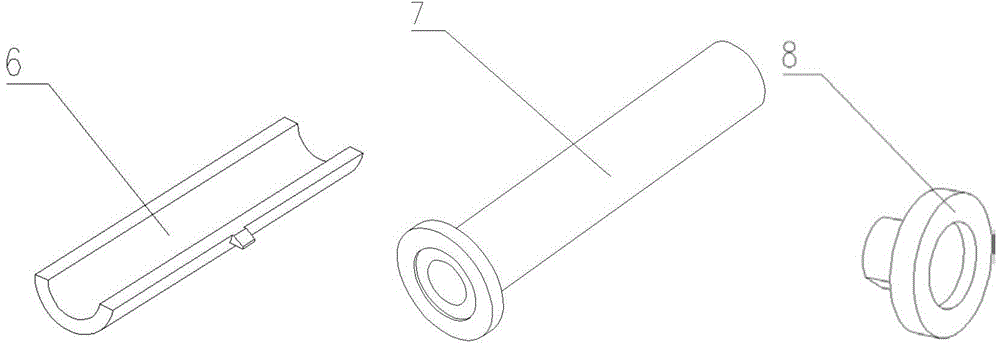

[0018] See attached figure 1 with 2 , a rubber wheel assembly device, comprising a base 1, an end block 2 is provided at one end of the base 1, a support block 4 is fixed at a certain position in the middle, and an optical axis 3 for assembly Placed on the block and the support block, the other end of the base 1 is provided with a cylinder 10, the piston rod of the cylinder 10 is along the direction of the optical axis, and a plurality of tops are arranged between the end of the piston rod and the optical axis 3 Blocks 7 and 9, the top block 7 is a hollow steel pipe, its inner diameter is slightly larger than the outer diameter of the optical axis, and a disc wheel is welded around the outer side of one end, the size of the disc wheel is similar to that of a rubber wheel, and the optical axis There is also a detachable equidistant clamp 6 on the top, and equal height blocks 8 can be provided between the plurality of top blocks.

[0019] The cylinder 10 directly pushes the ru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com