Longitudinal seam welding machine suitable for thin-wall small-diameter suspended single-face welding and double-face forming

A single-sided welding double-sided, longitudinal seam welding technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., to ensure straightness, reduce welding deformation, improve coaxiality and straightness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 3

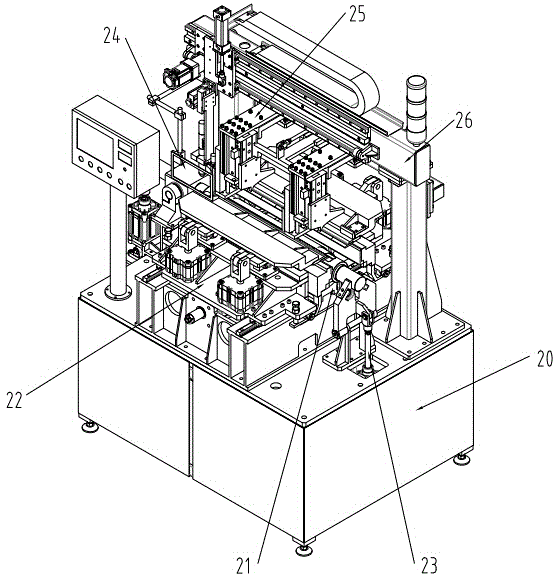

[0068] A longitudinal seam welding machine suitable for thin-walled small-diameter, suspended single-sided welding and double-sided forming includes a frame 20, on which a positioning workpiece device 21, a closing and pressing device 22, a mandrel supporting device 23, and a core Shaft device 24, centering device 25 and traveling gantry welding device 26.

[0069] The positioning workpiece device 21 is fixed on the middle position of the frame 20, and the closing pressing device 22 includes a first closing pressing device and a second closing pressing device, and the first closing pressing device and the second closing pressing device The devices are respectively located on both sides of the positioning device, and the first closing and pressing device and the second closing and pressing device are located on the slide rail and connected with the horizontal cylinder; the mandrel device 24 is located above the positioning device, when the mandrel device When 24 is in the horiz...

Embodiment 4

[0078] A longitudinal seam welding machine suitable for thin-walled small-diameter, suspended single-sided welding and double-sided forming includes a frame 20, on which a positioning workpiece device 21, a closing and pressing device 22, a mandrel supporting device 23, and a core Shaft device 24, centering device 25 and traveling gantry welding device 26.

[0079] The positioning workpiece device 21 is fixed on the middle position of the frame 20, and the closing pressing device 22 includes a first closing pressing device and a second closing pressing device, and the first closing pressing device and the second closing pressing device The devices are respectively located on both sides of the positioning device, and the first closing and pressing device and the second closing and pressing device are located on the slide rail and connected with the horizontal cylinder; the mandrel device 24 is located above the positioning device, when the mandrel device When 24 is in the horiz...

Embodiment 5

[0090] A longitudinal seam welding machine suitable for thin-walled small-diameter, suspended single-sided welding and double-sided forming includes a frame 20, on which a positioning workpiece device 21, a closing and pressing device 22, a mandrel supporting device 23, and a core Shaft device 24, centering device 25 and traveling gantry welding device 26.

[0091] The positioning workpiece device 21 is fixed on the middle position of the frame 20, and the closing pressing device 22 includes a first closing pressing device and a second closing pressing device, and the first closing pressing device and the second closing pressing device The devices are respectively located on both sides of the positioning device, and the first closing and pressing device and the second closing and pressing device are located on the slide rail and connected with the horizontal cylinder; the mandrel device 24 is located above the positioning device, when the mandrel device When 24 is in the horiz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com