Momentum wheel based on moving coil motor

A momentum wheel and moving coil technology, applied in the field of momentum wheels, to achieve stable operation, strong controllability, and performance change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Combine below figure 1 , figure 2 The present invention is further described in detail with specific examples.

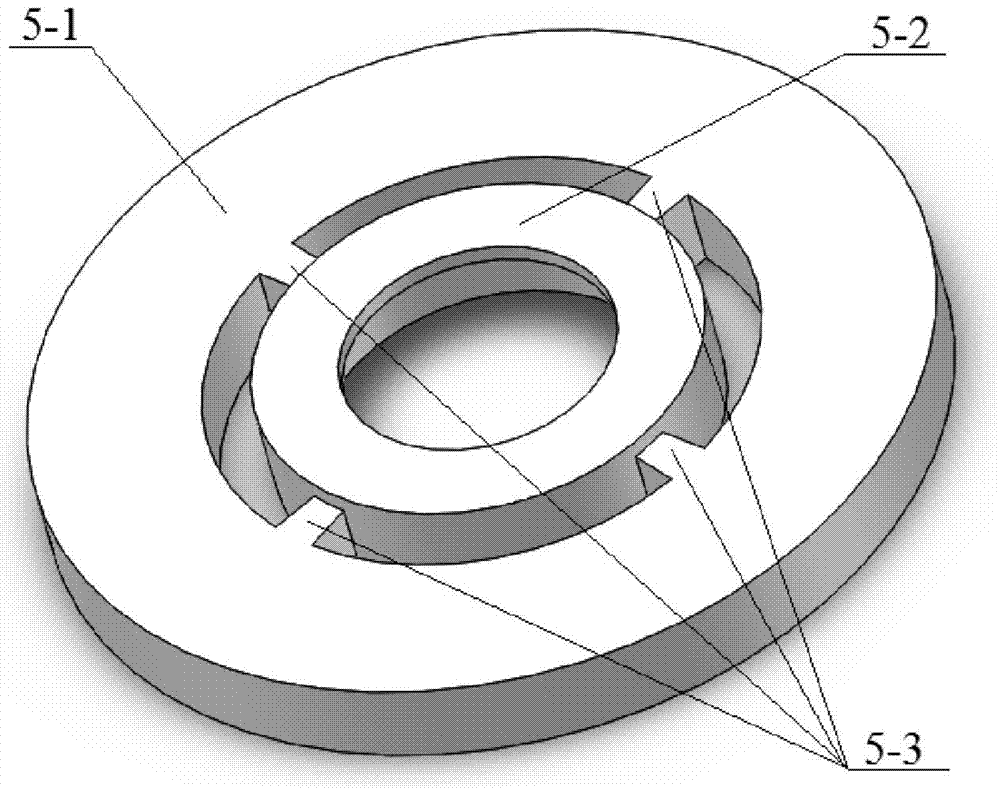

[0021] Such as figure 1 As shown, a momentum wheel based on a moving coil motor in the present invention includes a housing base 4, a housing upper cover 1 fixed on the housing base 4, and a cavity is formed between the housing upper cover 1 and the central support column of the housing base 4 , the inner ring of the rotating shaft 7 is fixed on the outer peripheral ring of the center support column of the shell base 4 in the cavity, and the rotor core 5 is fixed on the outer ring of the rotating shaft 7 in the cavity, and the coil 2 is wound on the rotor iron core 5, and the rotor The iron core 5 and the coil 2 jointly constitute the rotor part of the momentum wheel, and the stator part of the motor, that is, the permanent magnet 3, is respectively fixed on the upper and lower parts of the rotor iron core 5 and the coil 2, the inner wall of the casing upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com