cone connector

A connector and tapered technology, applied in the field of optical communication, can solve the problems of inability to meet the mechanical properties of the ferrule, breakage, affecting the transmission of optical signals, etc., to achieve the effect of fewer assembled components, reduced workload, and reduced production of finished products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

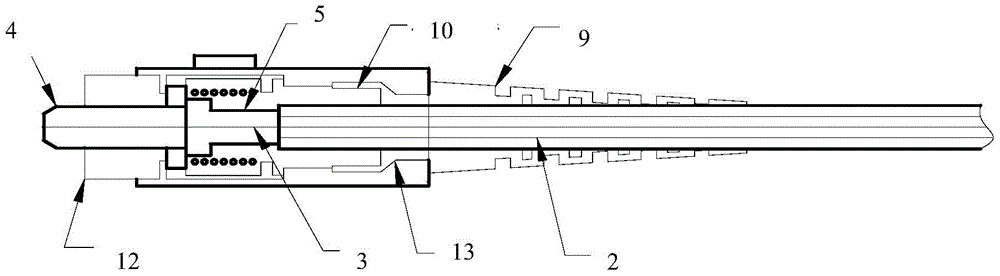

[0031] In this example the tapered connector, such as Figure 5 As shown, it includes a tapered tail handle 7 , ferrule 4 , shell 8 , boot 9 , positioning piece 10 , spring 11 and inner column 12 .

[0032] Wherein, the structure of tapered tail handle 7 and ferrule 4, such as Image 6 As shown, the tapered tail handle 7 is connected to the ferrule 4, the positioning member 10 is sleeved on the connecting part of the tapered tail handle 7 and the butterfly optical cable 6, and the inner column 12 is sleeved on the ferrule 4, and is connected with the The positioning elements 10 are connected.

[0033] Wherein, the tapered tail handle 7 is a tapered sleeve, and the inner side of the ferrule 4 is provided with a small hole, and the top of the tapered sleeve is fixedly connected with the ferrule 4, as Figure 7As shown, the front end of the butterfly optical cable 6 is stripped to form the bare fiber section at the front end, the strength member 2 and the coated fiber section a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com