Buffering system and device for large concrete batching plant rotary table

A buffer system and concrete technology, which is applied in the direction of mixing operation control device, clay preparation device, mixing operation control, etc., can solve the problem of damage to the rotary system, and achieve the effects of large buffer energy absorption, stable buffer, and protection of structures and devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

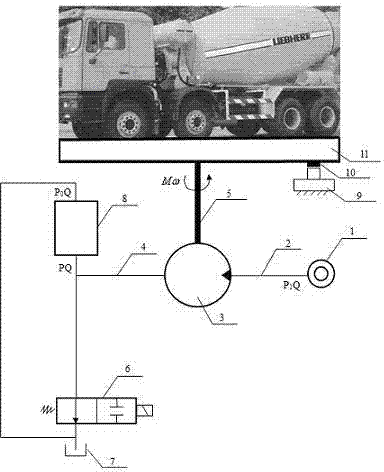

[0015] Embodiment 1: Large-scale concrete mixing station rotary table buffer system and device, characterized in that: the system and device include hydraulic energy (1), high-pressure oil inlet pipe (2), quantitative motor (3), oil return pipe (4), quantitative Motor output shaft (5), on-off switch solenoid valve (6), oil tank (7), energy absorber (8), non-contact switch static point (9), non-contact switch dynamic point (10), rotary work platform (11), the non-contact switch moving point (10) is fixed on the lower bottom surface of the rotary table (11), and the non-contact switch static point (9) is fixed on the ground;

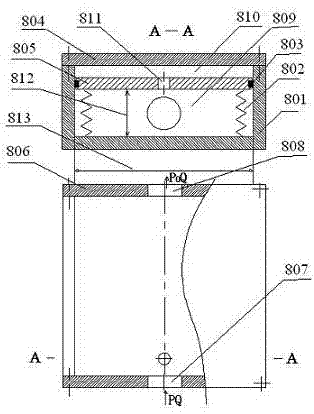

[0016] The energy absorber (8) includes an energy absorbing shell (801) fixedly connected to the front and rear end covers (806) to form a cuboid with an inner groove, and the floating pressure balance side plate (805) is a cuboid on the cuboid A dynamic fit is formed in the groove, and there are sealing strips (803) around the floating pressure balance si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com