Method for accurately implanting large-diameter pile casing into strong wave flow force inclined bare rock

A large-diameter, casing technology, which is applied in construction, sheet pile walls, and foundation structure engineering, can solve problems such as difficult positioning and installation of casings, large inclination height differences on bare rock surfaces, and steel casings driving into rock formations, etc. , to achieve the effect of reducing the impact, the impact of wave force is accurate, and reducing the tidal current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Specific embodiments of the invention will be described in detail below in conjunction with the accompanying drawings.

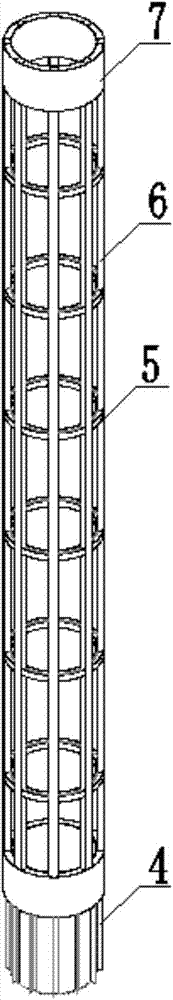

[0018] Such as figure 1 As shown, a tool casing suitable for the precise implantation method of a large-diameter casing in inclined bare rock with strong wave force, including a casing body, a ferrule 7 and a drill bit 4. The pipe 6 and a plurality of rings 5, each ring 5 is used to connect a plurality of pipes 6, the plurality of rings 5 are distributed along the extension direction of the pipe 6, and a ferrule 7 is sleeved at both ends of the main body of the casing, and the ferrule 7 is formed by A double-layer circular ring structure composed of the outer ring steel pipe and the inner ring steel pipe socket, the outer ring steel pipe and the inner ring steel pipe form an annular cavity, the pipe 6 extends into the annular cavity, and the connection gap between the annular cavity and the pipe 6 is filled with concrete , the drill bit 4 is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com