Construction method and device for hoisting of heavy and large part of vertical ship lift

A vertical ship lift and hoisting device technology, which is applied to vertically lift ship machinery, ship lifting devices, buildings, etc., can solve problems such as difficult hoisting, large hoisting safety hazards, and long hoisting time, so as to reduce structural impact and save energy. The effect of investment and time saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

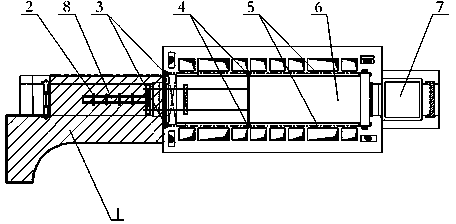

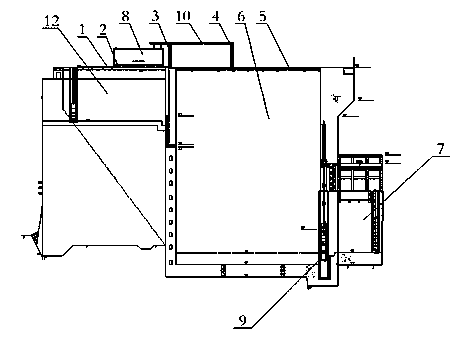

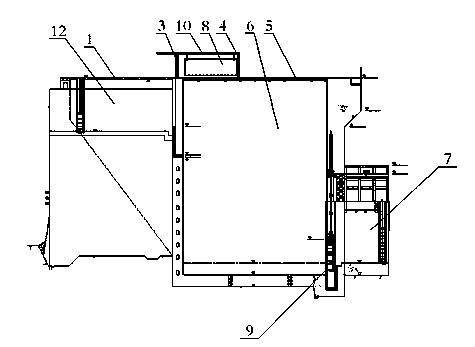

[0029] look figure 1 , and combined with figure 2 , the present invention is used to transfer and hoist the ship-carrying box 8 from the top of the dam-passing channel 12 to the ship-carrying box tooling platform 11 of the body section 6. The ship-carrying box 8 is usually provided with longitudinal beams or beams, and the dam-passing channel 12 is located at the barrier The upper part of the water building, and the ship-holding box tooling platform 11 is located at the bottom of the body section 6 of the downstream side of the water-retaining structure. There is a water level difference between the two, which cannot be directly navigated. The hoisting and transshipment of heavy items between them. It can be seen from the figure that the ship-holding box tooling platform 11 is located behind the downstream working gate 9 , that is, the upstream surface, and the downstream working gate 9 is provided with a lower gate head 7 . The present invention is provided with the trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com