A rubber fender

A technology for rubber fenders and ship posts, which is applied in shipping equipment, climate change adaptation, etc., can solve the problems of high maintenance and renewal costs, high engineering costs, and a large number of rubber fenders, so as to reduce the number of use and save engineering. The effect of construction cost and maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

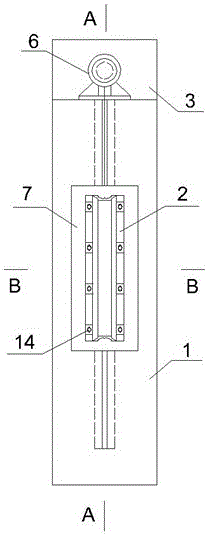

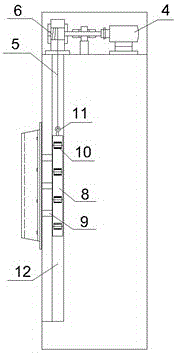

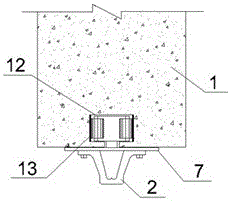

[0021] The rubber fender device of the present invention includes a berth post 1 and a rubber fender 2 , the rubber fender device also includes a lifting mechanism, the rubber fender 2 is slidingly connected to the berth post 1 , and the lifting mechanism is connected to the rubber fender 2 . The lifting mechanism is used to pull the rubber fenders to slide up and down along the height direction of the berthing column, which can meet the requirements of ships berthing under different water levels and different ship tonnages, greatly reducing the number of rubber fenders used at the wharf, saving engineering costs and maintenance costs.

[0022] The lifting mechanism includes a motor 4, a drum 6 and a traction cable 5, the motor 4 drives the drum 6, one end of the traction cable 5 is wound on the drum 6, and the other end is connected with the rubber fend...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com