A Temporary Aligner for Ribbon Optical Fiber

A ribbon optical fiber and aligner technology, which is applied in the coupling of optical waveguides, can solve the problems of complex and cumbersome fusion splicing operations, material consumption, etc., and achieve the effects of improving work efficiency and simplifying temporary docking operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

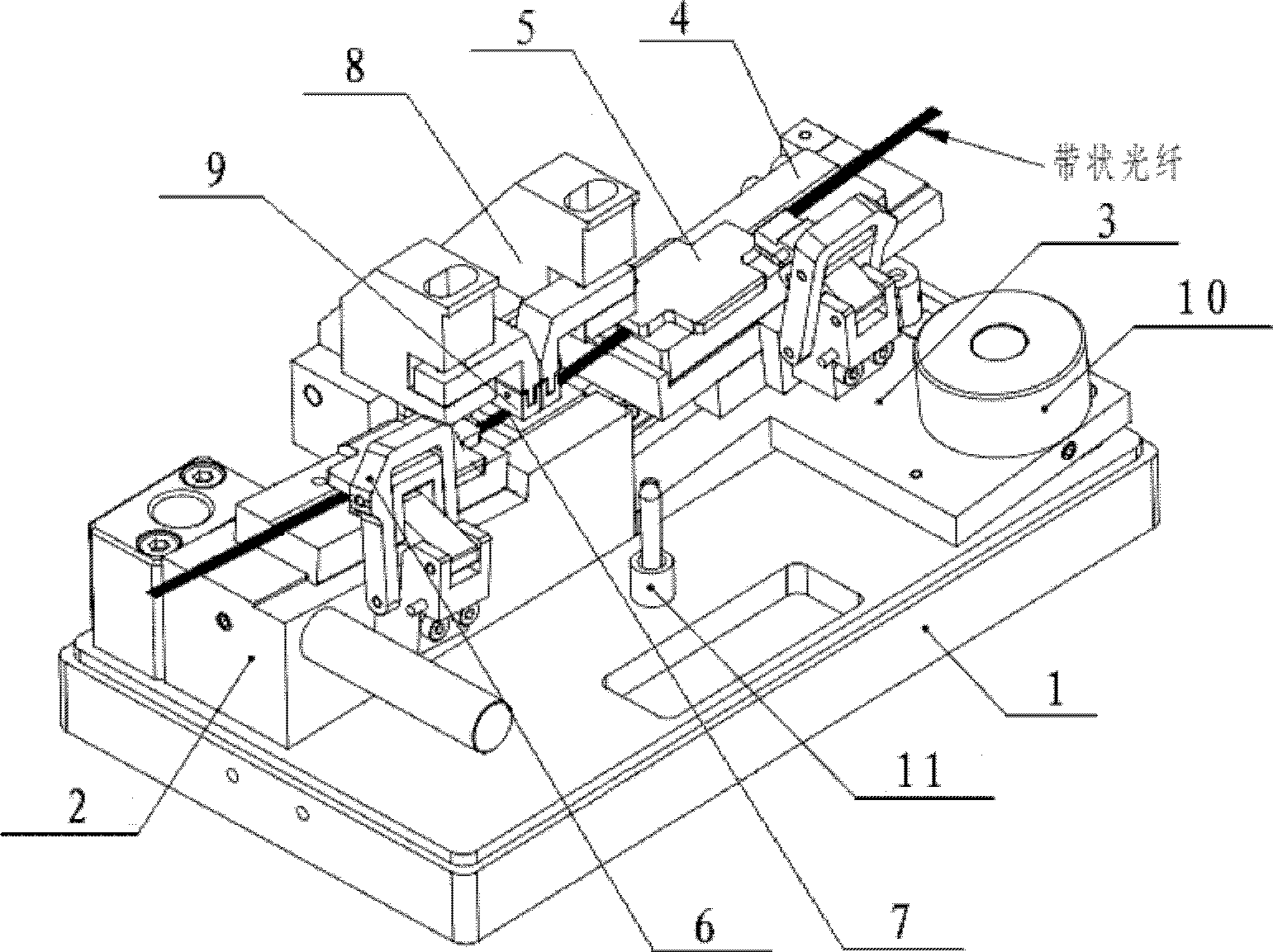

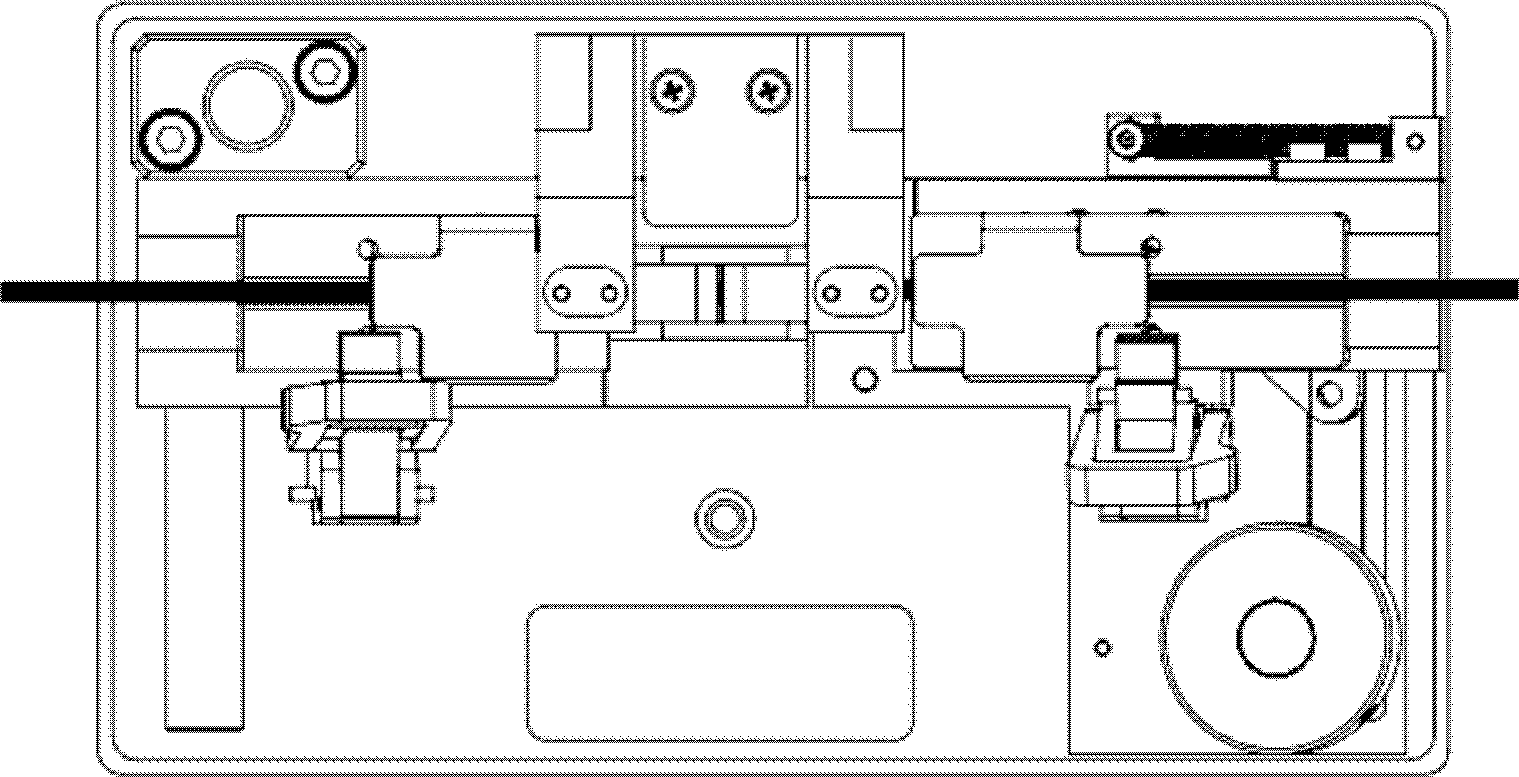

[0017] like figure 1 As shown, a ribbon-shaped optical fiber temporary aligner includes a base 1, a left fixture seat 2 is fixedly installed on the base 1, a right fixture seat 3 is slidably installed, and a left fixture seat 2 and a right fixture seat 3 are respectively installed with The bottom plate 4 and the pressure block 5 are attracted to each other, and the chucks 6 are respectively hinged to clamp the bottom plate 4 and the pressure block 5. The right end of the left clamp seat 2 is equipped with a V-groove 7 that cooperates with the ribbon-shaped bare fiber. The left clamp seat 2 is also hinged with a pressure head 8 for pressing on the V groove 7, and the right clamp seat 3 can make the bare fiber part of the ribbon optical fiber clamped on it extend into the V groove 7 through a sliding operation, and connect with the left Ribbon fiber alignment in holder 2.

[0018] Both the left fixture seat 2 and the right fixture seat 3 are provided with guide bosses, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com