Device and method thereof for drying wet-based coal at low temperature with low oxygen

A wet-based, coal-based technology, applied in the coal field, can solve problems such as low safety, unfavorable drying, flammability and explosion, and achieve the effects of reducing pollution, saving energy consumption, and operating safely

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

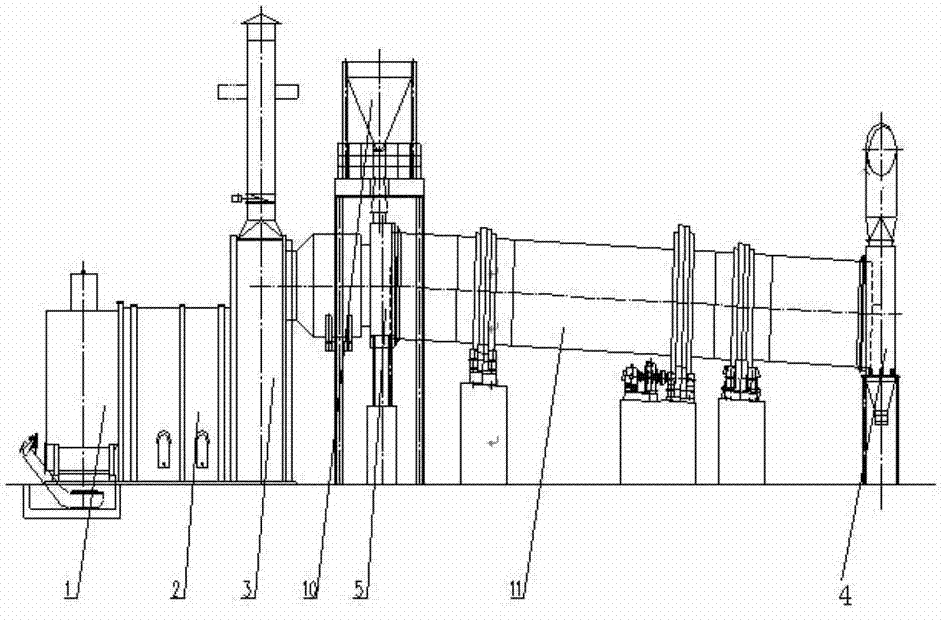

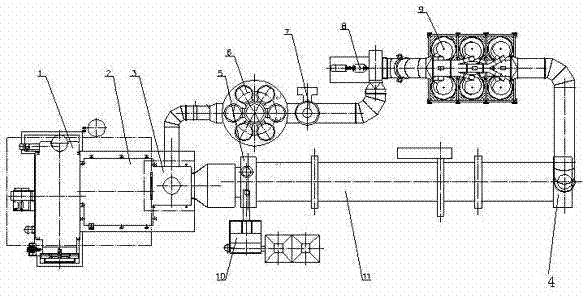

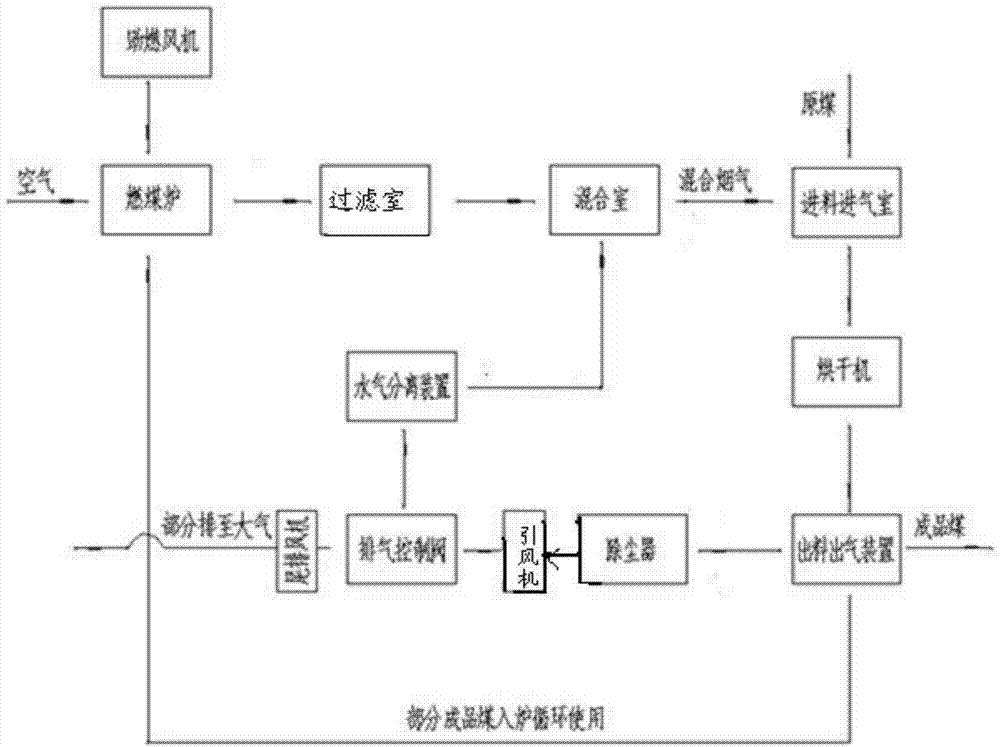

[0027] A device for drying wet-based coal at low temperature and low oxygen according to the embodiment of the present invention, such as figure 1 and figure 2 As shown, it includes a coal-fired furnace 1, a dryer 11, a blanking and gas outlet device 4 connected in sequence through pipes, a feeding device is connected to the body of the dryer 11, and a flue gas purification device and a flue gas are also included. Monitoring device, the dryer 11, the blanking and gas outlet device 4 are located between the flue gas purification devices, and the three together form a circulation loop; the flue gas monitoring device is located between the coal-fired furnace 1 and the flue gas purification device.

[0028] Further, a combustion-supporting fan is also connected to the inner cavity wall of the coal-fired furnace 1 .

[0029] Further, the flue gas monitoring device is a filter chamber 2 that can be used to remove open flames and fly ash at the same time, and the filter chamber 2 c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com