Technology for preparing organic fertilizer from blue algae, reed, and paddy rice straw

A technology of rice straw and organic fertilizer, which is applied to the preparation of organic fertilizer, organic fertilizer, and the treatment of biological organic parts, which can solve the problems of polluting the environment and achieve the effect of good water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

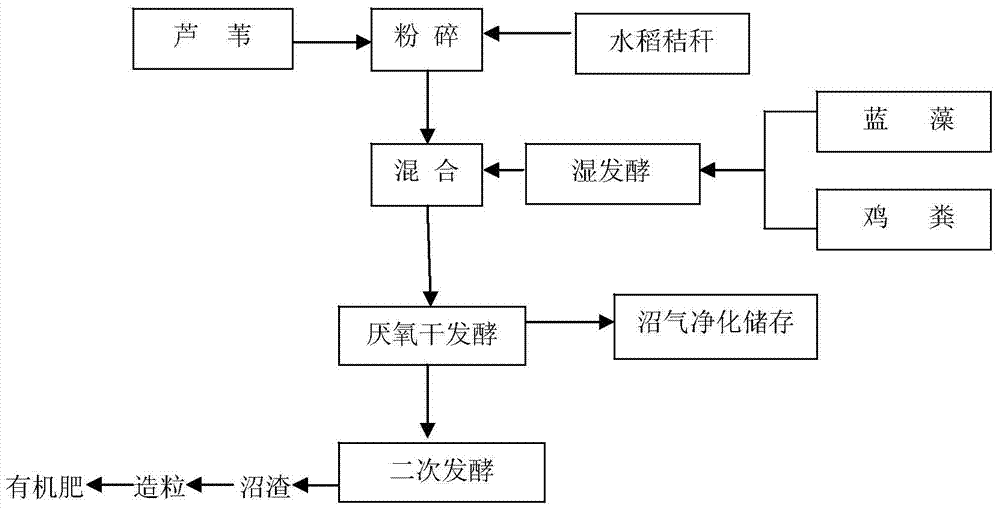

Method used

Image

Examples

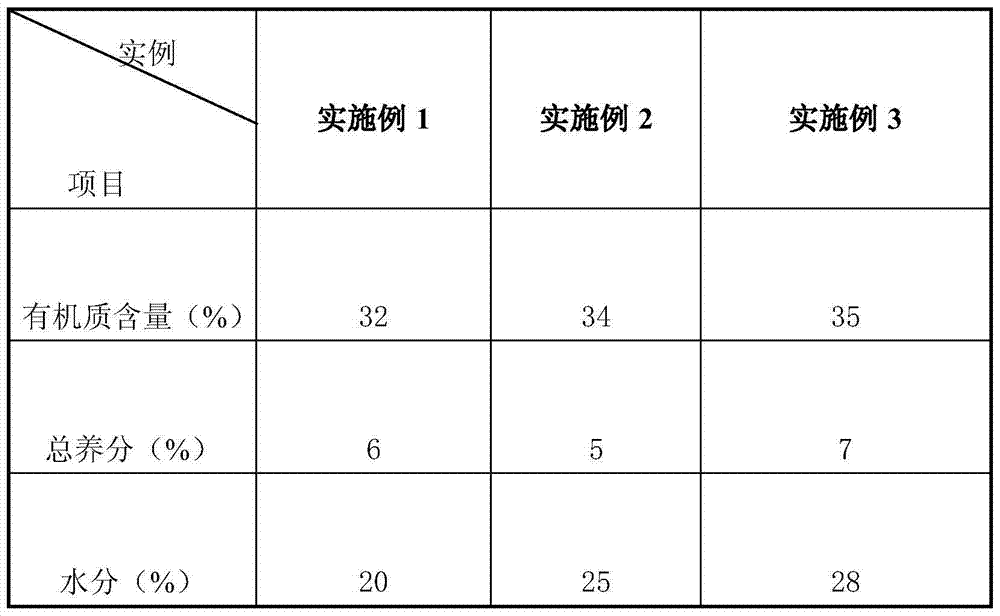

Embodiment 1

[0024] 15kg of cyanobacteria with a water content of 95% are mixed with 3kg of chicken manure for wet fermentation, and biogas slurry and biogas residue are obtained after fermentation.

[0025] Cut off the 1 / 4 stem tip of the front end of the reed, crush the rice straw and the intercepted stem tip of the reed into small pieces with an average length of 1 cm, and mix the crushed rice straw and reed at a mass ratio of 2:1 to obtain crushed material for later use. .

[0026] Take 8kg of the above pulverized material and enter the mixing device together with the biogas residue and biogas slurry obtained after the above wet fermentation. After mixing evenly, the materials enter the dry anaerobic fermentation device together. 0.72m gas was collected 3 .

[0027] The biogas residue enters the secondary fermentation device again, and is aerobic and aerobic fermented in a water bath at a constant temperature of 50°C for 25 days, and the feed is turned over every 5 days. After the pr...

Embodiment 2

[0029] Take 15kg of blue-green algae with a water content of 90% and 4kg of duck manure to carry out wet fermentation, and obtain biogas slurry and biogas residue after fermentation.

[0030] Cut off 1 / 3 of the stem tip of the front end of the reed, crush the rice straw and the cut stem tip of the reed into small pieces with an average length of 2 cm, mix the crushed rice straw and the reed at a mass ratio of 1:1 to obtain crushed material for later use .

[0031] Take 9kg of the above pulverized material and enter the mixing device together with the biogas residue and biogas slurry obtained after the above wet fermentation. After mixing evenly, the materials enter the dry anaerobic fermentation device together. Under the condition of a water bath with a constant temperature of 25°C, anaerobic dry fermentation is carried out for 25 days. Gas production of 0.68m was collected 3 .

[0032] The biogas residue enters the secondary fermentation device again, and is aerobic and ae...

Embodiment 3

[0034] 15kg of cyanobacteria with a water content of 90% are mixed with 5kg of pig manure for wet fermentation, and biogas slurry and biogas residue are obtained after fermentation.

[0035] Cut off 1 / 3 of the stem tip of the front end of the reed, crush the rice straw and the cut stem tip of the reed into small pieces with an average length of 5 cm, and mix the crushed rice straw and reed at a ratio of 3:1 to obtain crushed material for later use.

[0036] Take 10kg of the above-mentioned pulverized material and enter the mixing device together with the biogas residue and biogas slurry obtained after the above-mentioned wet fermentation. After mixing evenly, the materials enter the dry anaerobic fermentation device together. 0.65m of gas is collected 3 .

[0037] The biogas residue enters the secondary fermentation device, and is aerobic and aerobic fermented in a water bath at a constant temperature of 45°C for 25 days, and the feed is turned over every 7 days. After the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com