Improvement Method of Abrasion Resistance of Cement Concrete Pavement

A technology of cement concrete and wear resistance, which is applied in the field of road construction, can solve the problems of production cost, road performance limitation of construction technology, difficulty in popularization and implementation, etc., and achieve the effect of easy control of construction quality, easy promotion and application, and improvement of surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

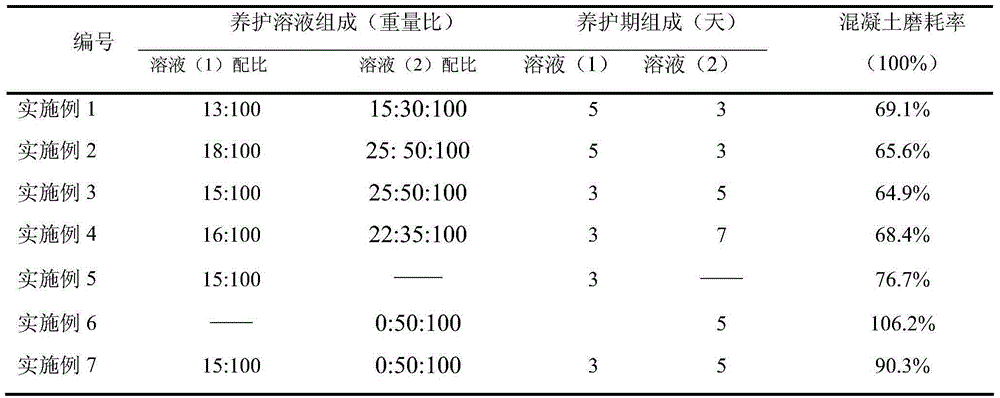

Examples

Embodiment Construction

[0020] The present invention will be described in detail below.

[0021] A method for improving the wear resistance of cement concrete pavement, comprising the following steps:

[0022] 1) After the cement concrete pavement is formed, spray K once before the initial setting of the concrete 2 CO 3 aqueous solution;

[0023] 2) After the initial setting of concrete, use K 2 CO 3 Water solution curing concrete for 3-5 days, spray once a day;

[0024] In steps 1 and 2), the K 2 CO 3 K in aqueous solution 2 CO 3 The mass ratio to water is 13-18:100, preferably 15:100, and the dosage per square meter of cement concrete pavement is 120-150 grams.

[0025] 3) Use the aqueous solution of composite polycarboxylic acid-based high-efficiency water-reducing agent and shrinkage reducing agent to maintain the concrete surface for 3-7 days, and spray once a day. In the aqueous solution of composite polycarboxylic acid-based high-efficiency water-reducing agent and shrinkage reducing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com