Potassium nitrate production process by double decomposition-air cooling crystallization method

A technology of cooling crystallization and air cooling, which is applied to the preparation of alkali metal nitrates, etc., can solve the problems of large consumption of cooling water and steam, poor quality of ammonium chloride products, and low output of potassium nitrate, achieving remarkable energy saving effects and improving raw materials conversion rate and the effect of improving product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

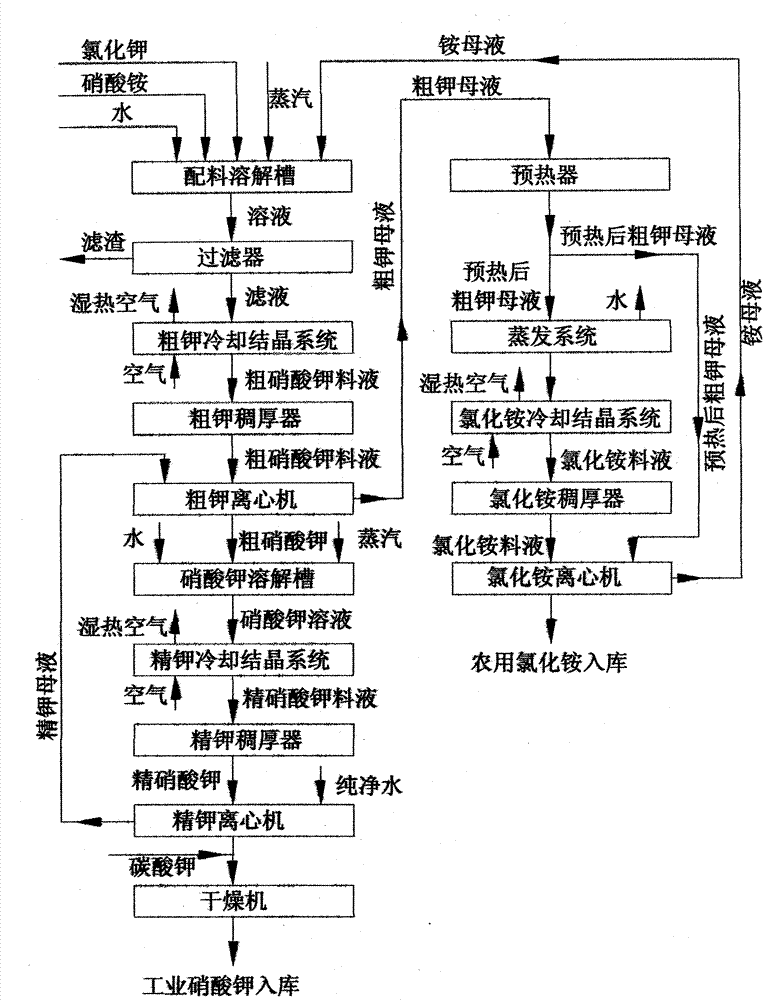

[0025] Such as figure 1 , figure 2 Shown, the present invention's metathesis air-cooled crystallization method produces potassium nitrate technique, and it is to take Repone K and ammonium nitrate as raw material, produces potassium nitrate and ammonium chloride by metathesis reaction and air-cooled crystallization, the present invention implements by following way :

[0026] (1) Mix potassium chloride, ammonium nitrate and water in a certain proportion and add them to the ingredients dissolving tank, feed steam to heat directly, stir to dissolve potassium chloride and ammonium nitrate, and prepare nitric acid at a temperature of 70-100°C The molar ratio of ammonium to potassium chloride is (1.35-1.8): 1, and the mixed solution of Baume concentration is 35-44Be.

[0027] (2), after the prepared solution is sent to the filter to filter and remove impurities, the filtrate is sent to the crude potassium cooling crystallization system and the air cooling crystallization process...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com