Honey tomato juice and preparation method thereof

A technology for tomato juice and honey, which is applied in food preparation, food shearing, food heat treatment, etc., can solve the problems of single tomato paste and insufficient nutrition, and achieve the effect of enhancing endurance, uniform state and supplementing nutritional value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

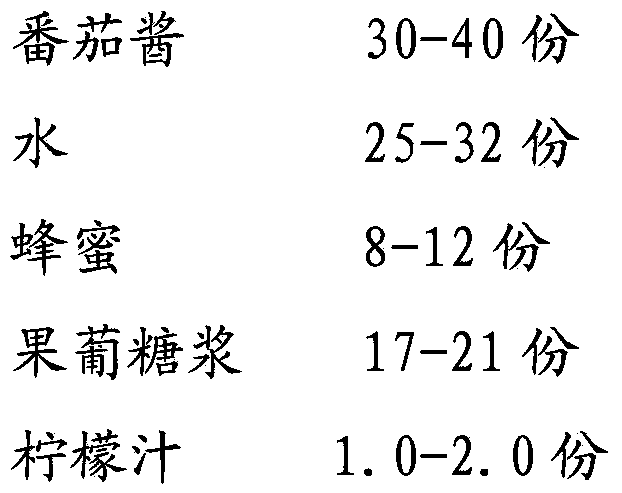

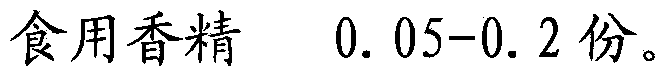

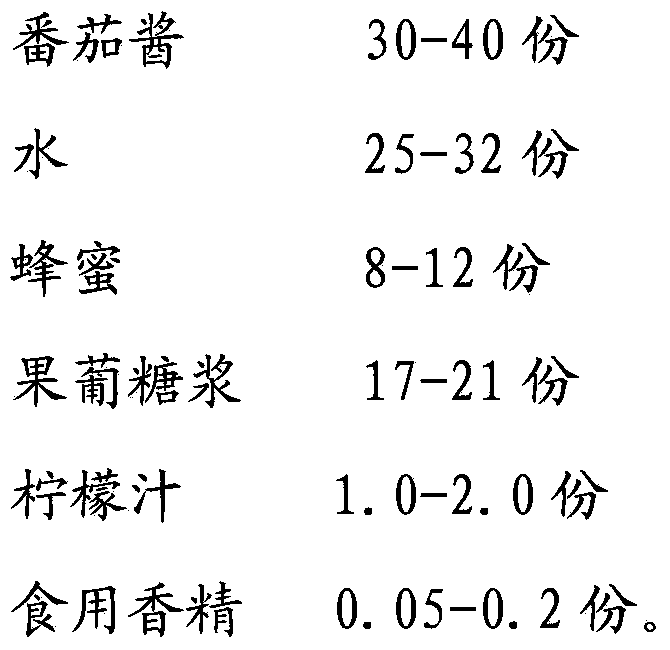

[0022] Add 30Kg tomato paste and 25Kg water to the tank and stir to dissolve the tomato paste and disperse the tomato paste evenly, then add 10Kg honey, 17Kg fructose syrup, 1Kg lemon juice, 0.025Kg tomato essence, 0.025Kg lemon essence The materials must be stirred and dispersed; then heated, mixed and stirred, the heating temperature is 40°C, low-temperature heating can effectively ensure the flavor and properties of honey, after heating for 15 minutes, it is cut by a 2600rpm shear pump, and then degassed for 5 minutes; The heating tube is heated at 90°C; the heated material is pumped to the filling machine for hot filling at 88°C. The canned products enter the steam sterilization tunnel at 87°C for 3 minutes to sterilize for a short time to ensure the sterilization effect while preserving the flavor and color of the product as much as possible; the sterilized products are cooled to below 50°C. The final state of honey tomato juice is uniform, no peculiar smell, red or orang...

no. 2 example

[0024] Add 40Kg tomato paste and 32Kg water to the tank and stir to dissolve the tomato paste and disperse the tomato paste evenly, then add 12Kg honey, 21Kg fructose syrup, 2Kg lemon juice, 0.1Kg tomato essence, 0.1Kg lemon essence The materials must be stirred and dispersed; then heated, mixed and stirred, the heating temperature is 45°C, low-temperature heating can effectively ensure the flavor and properties of honey, after heating for 10 minutes, it is cut by a 2600rpm shear pump, and then degassed for 5 minutes; The heating tube is heated at 92°C; the heated material is pumped to the filling machine for hot filling at 90°C. The canned products enter the steam sterilization tunnel at 90°C for 2 minutes to sterilize for a short time to ensure the sterilization effect while preserving the flavor and color of the product as much as possible; the sterilized products are cooled to below 50°C. The final honey tomato juice is in a uniform state, no peculiar smell, red or orange;...

no. 3 example

[0026] Add 35Kg tomato paste and 27Kg water to the tank and stir to dissolve the tomato paste and disperse the tomato paste evenly, then add 8Kg honey, 20Kg fructose syrup, 1.5Kg lemon juice, 0.1Kg tomato essence, 0.08Kg lemon essence, and All materials must be stirred and dispersed; then heated, mixed and stirred, the heating temperature is 42°C, low-temperature heating can effectively ensure the flavor and properties of honey, after heating for 13 minutes, it is cut by a 2600rpm shear pump, and then degassed for 5 minutes; the prepared materials The heating tube is heated at 90°C; the heated material is pumped to the filling machine for hot filling at 88°C. The canned products enter the steam sterilization tunnel at 85°C for 3 minutes to sterilize for a short time to ensure the sterilization effect while preserving the flavor and color of the product as much as possible; the sterilized products are cooled to below 50°C. The final state of honey tomato juice is uniform, no pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com